| Price | USD43.5PCS |

| MOQ | 1pc |

| Delivery Time | 5*7 days |

| Brand | CrownExtra |

| Place of Origin | CHINA |

| Certification | ATEX、CE、ISO、CNEX、RoHS |

| Model Number | BPY- Explosion Proof Fluorescent Tube Light |

| Packaging Details | CARTON、WOODEN BOX、PALLET |

| Payment Terms | T/T, Western Union |

| Supply Ability | 500000PCS Per Month |

| Ex Mark | Exd IIB T6 Gb/Ex tD A21 IP65 T80℃ | Place of Origin | CHINA |

| Packaging Details | CARTON、WOODEN BOX、PALLET | Model Number | BPY- Explosion Proof Fluorescent Tube Light |

| Supply Ability | 500000PCS Per Month | Certification | ATEX、CE、ISO、CNEX、RoHS |

| Brand Name | CrownExtra | Payment Terms | T/T, Western Union |

| Battery charging time | ≤24h | Cable outer diameter | Ф6mm—Ф10mm |

| Price | USD43.5PCS | Delivery Time | 5*7 days |

| Product name | Oil Gas Station Explosion Proof Fluorescent Tube Light Corrosion Proof Led Light | IP Rating | IP54, IP65, IP66 |

| Rated voltage | AC220V | Minimum Order Quantity | 1pc |

| Luminous Efficiency | 90-110lm/w | Emergency starting time | ≤0.3s |

| Emergency lighting time | ≤90min | Item type | Explosion Proof Fluorescent Tube Light |

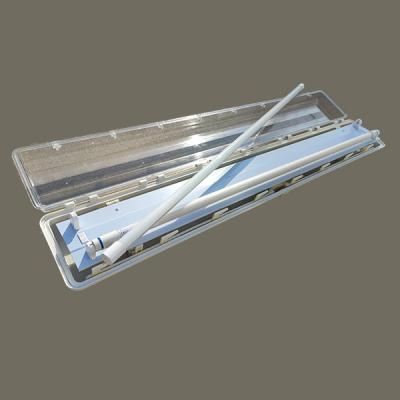

Oil Gas Station Explosion Proof Fluorescent Tube Light Corrosion Proof Led Light

Introduction

1.

Suitable

for

zone

1

and

zone

2

of

explosive

gas

environment;,

2.

Suitable

for

IIA.IIB

explosive

gas

environment:

3.

It

is

suitable

for

the

environment

where

the

temperature

group

is

T1~T6;

it

is

equipped

with

T8

two-foot

fluorescent

tubes;

4.

Suitable

for

explosive

and

dangerous

environments

such

as

petroleum

extraction,

storage,

chemical

industry,

medicine,

military

industry

and

military

facilities.

Features

1.

Aluminum

alloy

die-casting

shell,

the

surface

is

high-voltage

electrostatic

spray;

2.

High-strength

toughened

glass

transparent

tube;

3.

Stainless

steel

exposed

fasteners;

4.

The

lamp

is

equipped

with

a

grille

to

increase

the

light

efficiency

of

the

lamp

and

effectively

reduce

the

glare;

5.

Equipped

with

well-known

brand

fluorescent

tubes,

long

life

and

high

luminous

efficiency;

6.

Modular

plug-in

design,

you

only

need

to

loosen

the

end

cap

and

pull

out

the

core

to

replace

the

lamp;

7.

The

fluorescent

lamp

with

emergency

device

automatically

switches

to

the

emergency

lighting

state

when

the

power

supply

line

loses

power;

8.

There

are

specially

designed

overcharge

and

overdischarge

protection

circuits

in

the

emergency

device;

9.

Steel

pipe

or

cable

wiring.

Installation

and

maintenance

1.

The

sealing

ring

of

the

lead-in

device

should

be

reliably

pressed

and

the

cable

clamped;

2.

The

extra

unused

inlets

on

the

junction

box

matched

with

the

lamp

should

be

reliably

sealed

with

a

plugging

plate

and

a

compression

nut

to

ensure

explosion-proof

performance

and

protection

level

performance;

3.

Before

the

lamp

is

put

into

use,

the

internal

and

external

grounding

must

be

firmly

and

reliably

connected

to

the

user's

site

grounding

system;

4.

When

installing

and

maintaining

the

lamp,

it

is

strictly

forbidden

to

open

it

with

power;

5.

Regularly

check

the

sealing

ring,

if

it

is

found

to

be

aging,

it

should

be

replaced

in

time.

Technical Specification:

| 1 Compliance with:GB 3836.1,GB 3836.2,GB 3836.3,GB 12476.1,IEC60079-0,IEC60079-1 |

|

2 Explosion Protection: Exd IICT6 Gb / DIPA20TA, T6 |

|

3 Rated Voltage: AC 220V |

|

4 Tube options: T5/T8 Bi-pin fluorescent tubes(1*9W,2*9W,1*18W,2*18W,1*40W,2*40W) |

|

5 Ingress Protection:IP66 |

|

6 Corrosion Resistance:WF1 |

|

7 Cable Entries specification:2-G1/2 |

|

8 Cable’s outer dia.:Φ6mm~Φ10mm |

|

9 Charging time ≤24h |

|

10 Emergency starting time:≤0.3s |

|

11 Emergency lighting duration: ≥120min |