Good

Quality

Custom

Cutting

Edge

Width

500mm

Rebar

Shear

Line

Rebar

Shear

Line

SGS150

Product

Specifications

|

Attribute

|

Value

|

|

Video

Outgoing-Inspection

|

Provided

|

|

Machinery

Test

Report

|

Provided

|

|

Core

Components

|

Motor

|

|

Voltage

|

380V

|

|

Dimension

(L×W×H)

|

30×5×3

m

|

|

Power

(kW)

|

42

|

|

Weight

(kg)

|

15000

|

|

Key

Selling

Points

|

Easy

to

Operate

|

|

Warranty

|

1

Year

|

|

Cutting

Edge

Width

|

500mm

|

|

Shearing

Mode

|

Hydraulic

Shearing

|

|

Roller

Speed

|

0-100m/min

adjustable

|

|

Maximum

Shear

Length

|

12m

|

|

Minimum

Shear

Length

|

1.4m

|

|

Shear

Accuracy

|

±5mm

|

|

Shear

Frequency

|

≤12n/min

|

|

Silo

Series

|

3

|

|

Rated

Power

|

42kw

|

|

Total

Weight

|

15t

|

Product

Description

CNC

REBAR

SHEAR

LINE

SGS150

-

PLC

control

shearing

precision,

high

precision

of

finished

steel

bar,

suitable

for

shearing

processing

of

steel

bar

with

many

specifications

and

small

batches.

-

The

machine

has

24

fixed

length

plates,

all

steel

plate

structure,

with

fixed

length

servo

motor

for

fast

and

accurate

positioning.

-

Large

length

blade

and

inclined

blade

design

ensure

multiple

reinforcing

bars

can

be

cut

simultaneously.

-

Equipped

with

centralized

oil

supply

system

for

long

life

operation.

-

Level

3

product

storage

mechanism

facilitates

collection

of

multiple

products.

-

Thickened

and

widened

gears

for

stable,

efficient

cutting

with

fully

encapsulated

shield

for

enhanced

safety.

-

High

strength

spiral

elevator

for

positioning

screw

prevents

deformation

and

ensures

high

positioning

accuracy.

-

Cutting

length

can

be

set

arbitrarily

for

continuous

work

with

high

fixed-length

cutting

accuracy.

-

Key-guided

chains

with

rolling

friction

design

for

minimal

wear,

long

service

life,

and

high

transmission

efficiency.

Straightening

Structure

Straightening

wheel

made

from

forged

alloy

tool

steel

for

superior

wear

resistance

and

impact

resistance.

Preset

wheel

plate

constructed

from

30mm

thick

steel

plate

for

high

strength

and

durability

under

impact

load.

Multi-split

Type

Blade

Multi-split

type

blade

design

doubles

lifespan

compared

to

standard

one-piece

blades.

Servo

Motor

16KW

high-power

servo

motor

ensures

smooth

traction

operation.

Pneumatic

Element

Premium

Airtac

brand

pneumatic

components

from

Taiwan

ensure

extended

service

life.

Split

thickening

blade

design

with

40mm

thickness

for

multiple

uses.

Pay-Off

System

-

2

pay-off

units

per

machine

-

2500KG

maximum

carrying

capacity

per

pay-off

-

Designed

for

easy

disassembly

and

transport

-

Optional

brake

customization

available

Automatic

Collector

(Optional)

-

Automatically

collects

finished

stirrups

-

Adjustable

collection

quantity

settings

-

Simplifies

finished

product

packaging

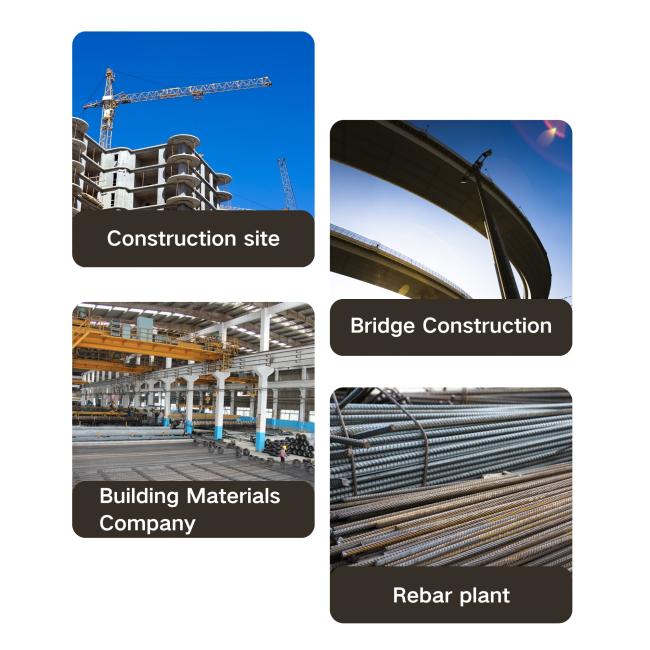

Application

Production

Line

Company

Profile

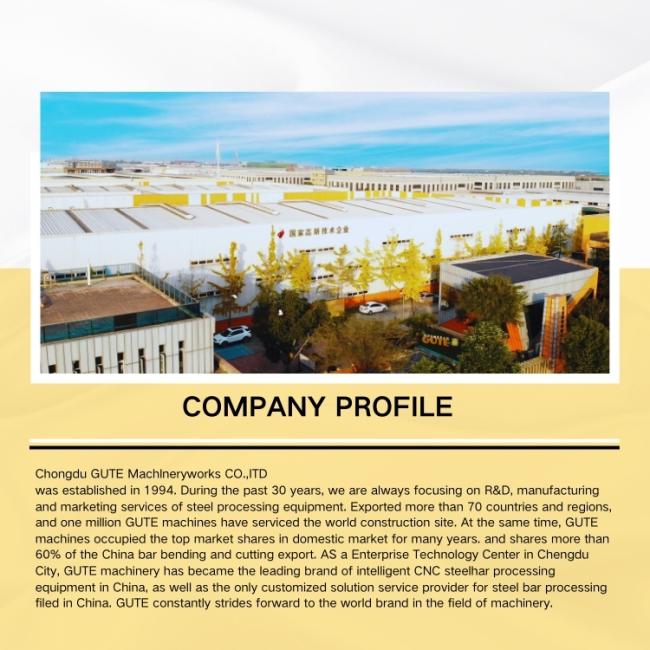

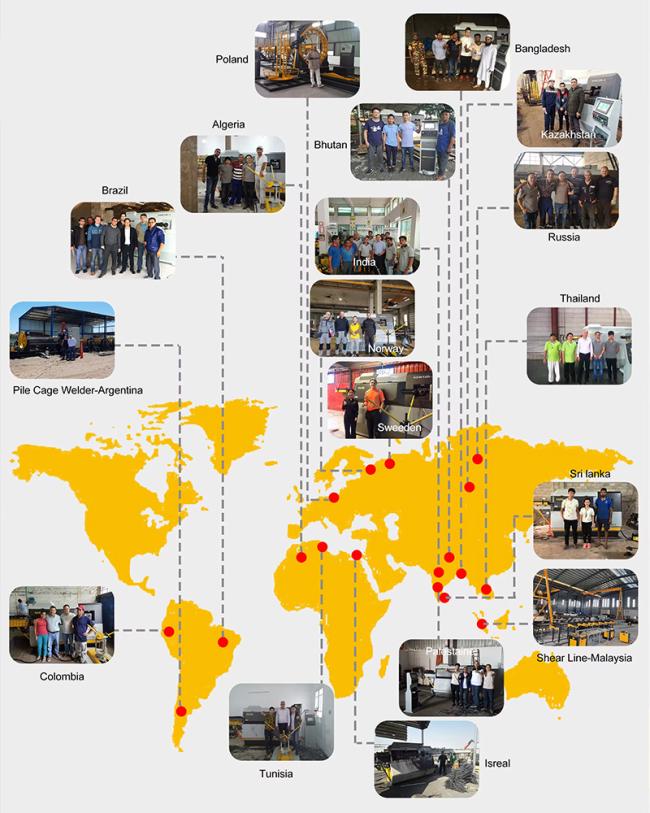

GUTE

is

a

manufacturer

of

construction

machinery

with

28

years

of

history

and

more

than

250

workers

producing

steel

bar

processing

machinery.

-

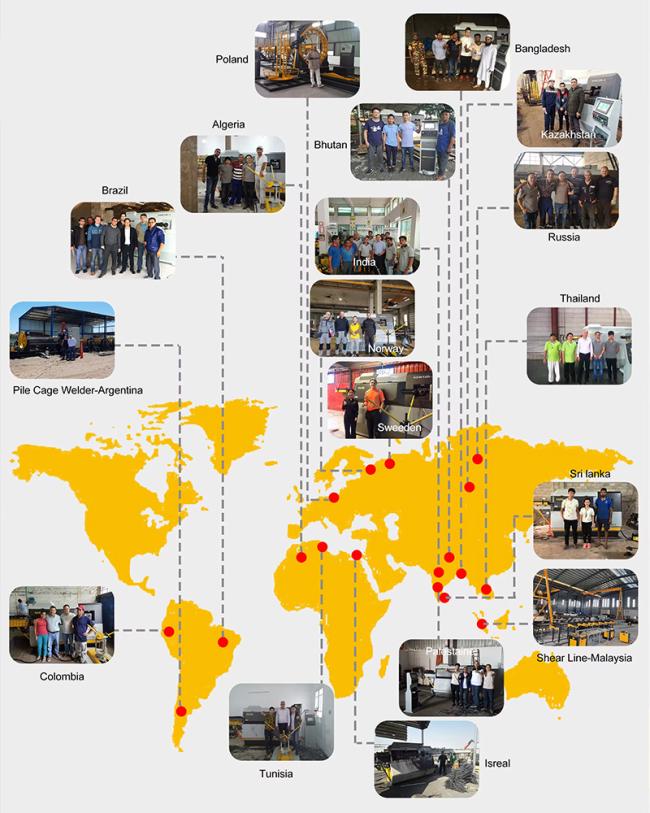

Exported

to

more

than

70

countries

with

70%

export

share

of

steel

bar

bender/cutter

-

Over

200

agents

in

Chinese

market

and

10

owned

brand

shops

across

China

-

OEM

provider

for

many

famous

European

brands

-

Machines

sold

to

Russia,

Italy,

Brazil,

Algeria,

India,

Argentina,

Saudi

Arabia,

Middle

East

and

more

than

70

countries

worldwide

-

Specialists

in

reinforcement

steel

bar

bending,

shearing,

welding,

and

straightening

machines

-

Expert

in

fast,

professional

customized

services

with

strong

R&D

and

quality

control

-

Manufacturer

of

highly

precise,

durable

semi-automatic

and

fully

automatic

steel

bar

machines

Transportation

Frequently

Asked

Questions

Q:

What's

the

producing

time

and

delivery

time?

A:

Order

less

than

5

pcs,

we

have

stock,

delivery

to

Shanghai

port

about

5

days.

And

order

more

than

5

pcs,

about

10-15

working

days.

Q:

What's

the

MOQ?

A:

5

pcs.

For

sample

order,

1

pc

is

OK,

there's

extra

port

and

delivery

charges.

Q:

What's

the

departure

port?

A:

Usually

Shanghai

port,

Guangzhou,

Qingdao,

Tianjin

and

other

Chinese

port

is

also

OK.

Q:

What's

the

packing?

A:

Iron

Pallet

and

Polly

wooden

cases

(no

fumigation

needed).

Q:

What's

the

payment

term?

A:

T/T,

L/C,

DP,

West

union,

PayPal.

Our

Service

-

Your

inquiry

related

to

our

products

or

prices

will

be

replied

in

24

hours

-

Protection

of

your

sales

area,

design

ideas

and

all

private

information

-

Best

quality

and

competitive

price