| Price | $80.00/Sheets 1-49 Sheets |

| MOQ | 100 Pieces |

| Delivery Time | 7-15work days |

| Brand | Grand Metal |

| Place of Origin | Guangdong, China |

| Certification | ISO |

| Model Number | HW-SSS-045 |

| Packaging Details | In bundles with seaworthy wooden pallets or as per requirement. The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM, max weight 28 tons 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 100000000000 Sheet/Sheets per Month |

| Place of Origin | Guangdong, China | Packaging Details | In bundles with seaworthy wooden pallets or as per requirement. The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM, max weight 28 tons 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about |

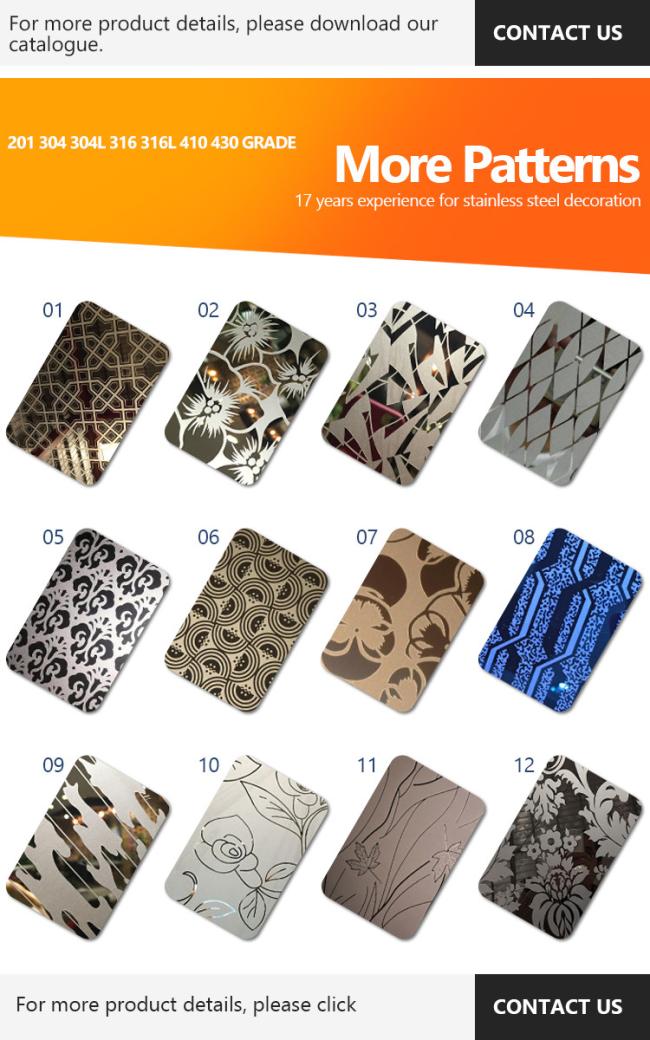

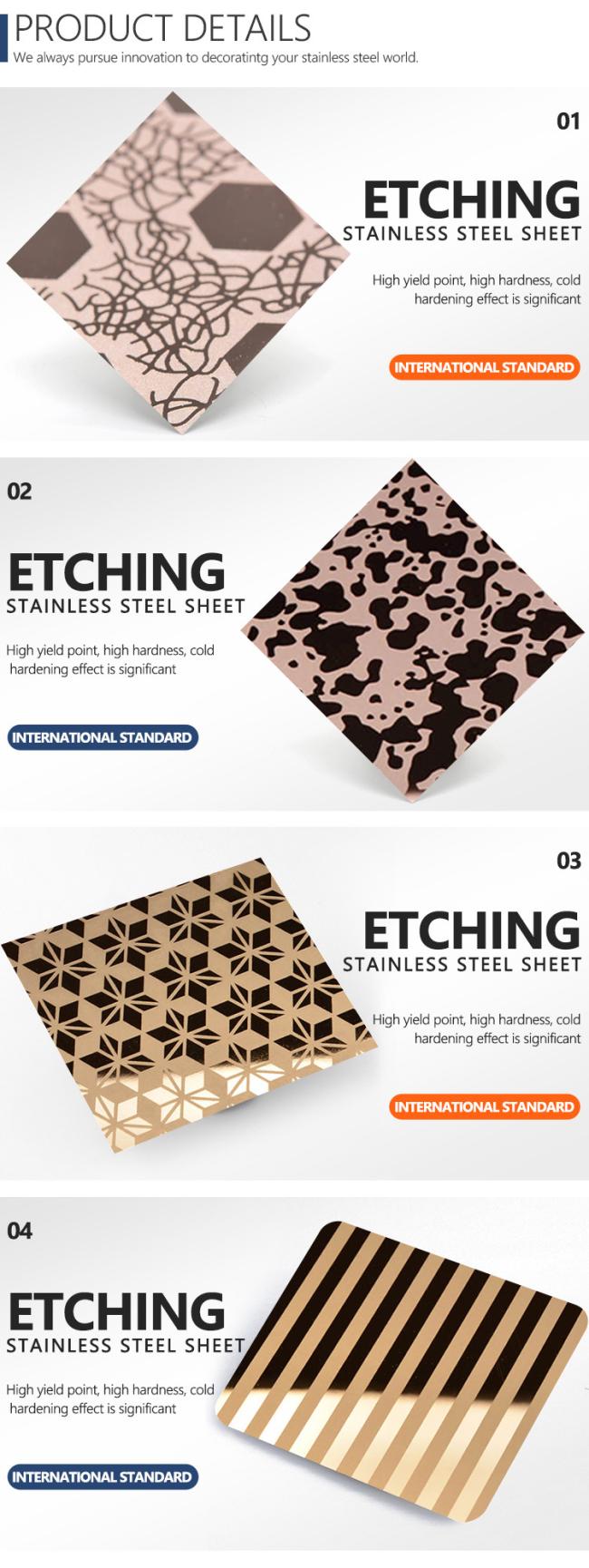

| Product type | 201 304 Color Hotel Home Decor Etched decorative Stainless Steel Sheet | Color | lots of color available |

| Tolerance | ±3% | Model Number | HW-SSS-045 |

| Supply Ability | 100000000000 Sheet/Sheets per Month | Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Certification | ISO | Brand Name | Grand Metal |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Thickness | 0.3-3mm |

| Type | Sheet/Plate | Price | $80.00/Sheets 1-49 Sheets |

| Delivery Time | 7-15work days | Minimum Order Quantity | 100 Pieces |

| Bending or Laser Cutting | available | Surface Finish | Etched |

| Application | wall decoration | MTC | provided |

| Product Information | |

| Product Name | China Original Factory Inner Decoration Hotel Elevator Panels 316 1.0mm Etched PVD Stainless Steel Decorative Sheets |

| Grade | Stainless Steel 201,304,316,etc. |

| Color | Gold, Rose Gold, Champagne Gold, Black, Wine Red, Rose Red, Violet, Emerald Green, Bronze, Red Copper, Sapphire Blue, Silver, etc.; Color Fastness for More Than 20 Years |

| Size |

1000×2000;1220×2440;1500×3000;1220×3050;

or

Customized

by

Customer Thickness: 0.3mm-3mm |

| Technology | 2b, BA, No.4, 8k, Hairline, Embossed, Etched, Vibration, PVD color Coated, Sand Blasted, Anti-fingerprint, Stamped, Satin Finish, Perforated, etc. |

| Samples | Free Sample, Freight Paid by Customers |

| Feature |

1.Anti-rust,Oxidation-resistant,

Anti-scar,

Non

Fading,

Waterproof

,

Corrosion-resistant 2.Eco-friendly, No Pollution, Durable and Strong |

| Usage |

1.Indoor

and

Outdoor

Decoration

Specially

for

Star

Rated

Hotel,

Restaurant,

Office,

Bar,

Club,

KTV,

Villa 2. Engineering Decoration 3. Wall and Ceiling Decoration |

| payment | TT 30% before production, 70% before shipment |

How to fill the stainless steel plate after etching?

Many people think that the stainless steel etched plate is etched after being plated, but it is not. Many technologies now make stainless steel plates etched first and then colored.

Etched

wood

grain

board

How

to

fill

in

the

color

after

the

stainless

steel

is

etched?

According

to

the

surrounding

color,

you

can

slant

the

gray

of

the

surrounding

color,

generally,

the

blue-gray

is

enough,

add

20-30

black,

and

other

ambient

colors

do

not

exceed

10.

Toning refers to changing a specific tone to form another tone picture with a different feeling. Toning is a technique that is most likely to confuse everyone and is very difficult to grasp in practice. Let many enthusiasts go around to discuss tutorials, and spend a lot of energy and time on color testing.

Color stainless steel plate is to use vacuum coating technology to evenly cover titanium or chromium metal on the surface of stainless steel plate, and produce different colors. The principle of vacuum coating technology is to use low-voltage, high-current arc discharge technology under vacuum conditions, use gas discharge to evaporate the target and ionize the evaporated material, and under the action of an electric field, make the evaporated material or its reaction. The product is deposited on the plate.

A

variety

of

decorative

color

plates

At

the

same

time,

the

following

matters

should

be

paid

attention

to

in

the

stainless

steel

products

coated

with

color

PVD

film:

1. Although the vacuum-plated PVD film has certain corrosion resistance, it is still difficult to resist the contact of strong corrosive substances such as acid and alkali. Therefore, in the usual maintenance, try not to use cleaning agents that contain strong acids and alkalis or have strong decontamination capabilities, such as toilet cleaners, paint strippers, metal cleaning agents, etc. You can use industrial alcohol to gently wipe with a soft cotton cloth. Dirt should also be treated with weak acid and weak base solvents. In addition, if exposed to harsh environments for a long time, or in contact with corrosive liquids for a long time, the PVD film layer is also prone to problems such as falling off, such as swimming pools (containing fluorine), seawater (containing a lot of salt), high temperature and high humidity (steam) etc. environment.

Various

pattern

etching

plates

2.

The

use

of

anti-fingerprint

varnish.

More

and

more

customers

choose

to

spray

a

layer

of

transparent

anti-fingerprint

clear

oil

on

the

stainless

steel

products

plated

with

color

PVD

film,

the

effect

is

obvious,

there

is

no

fingerprint

on

the

hand,

easy

to

clean,

and

it

can

also

increase

wear

resistance

and

resistance.

The

function

of

corrosion

can

serve

multiple

purposes.

However,

the

disadvantage

is

that

the

color

of

the

injected

and

uninjected

is

inconsistent,

and

the

processing

requirements

are

high

and

the

cost

is

not

low,

which

affects

the

metal

texture

of

the

product,

and

there

are

problems

such

as

aging.

Therefore,

it

must

be

carefully

considered

before

use.