| Price | Negotiable |

| MOQ | 50 |

| Delivery Time | 15-25 working days |

| Brand | Santon |

| Place of Origin | China |

| Certification | ISO |

| Model Number | SNMG250924ZM-M or customized |

| Packaging Details | Plastic boxes inside and cartons outside |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 2 million per month |

| Place of Origin | China | Place of Origin: Sichuan, China Applicable Industries | metal cutting industry |

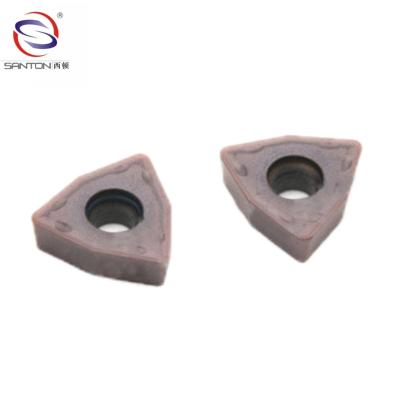

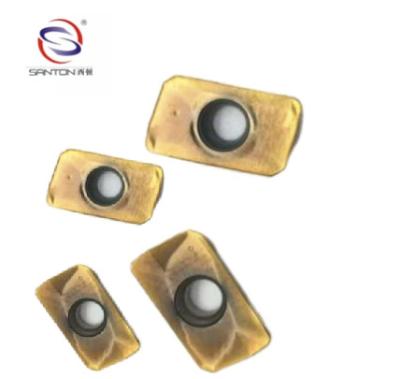

| Packaging Details | Plastic boxes inside and cartons outside | Product Name | Various Coating CNC Carbide Inserts |

| Grade | K30 | Model Number | SNMG250924ZM-M or customized |

| Supply Ability | 2 million per month | Certification | ISO |

| Brand Name | Santon | Payment Terms | L/C, T/T, Western Union |

| Video outgoing-inspection | Provided | material | tungsten carbide, cobalt,etc |

| Price | Negotiable | Delivery Time | 15-25 working days |

| Alias | industrial cutter knives | Minimum Order Quantity | 50 |

| Model | ISO standard, also can be customized | Machinery Test Report | Provided |

Tic TiN T(CN) TiALN ALTiN Coating Materials CNC Carbide Inserts

Product Information:

The main coating materials are :Tic, TiN, T(CN), TiALN, ALTiN, etc. Coating technology has been applied to vertical iron cutter, reamer, drill bit, composite hole machining tool, gear hob, gear shaper, gear shaving cutter, forming broach and various machine clamping indexable blades. Meet the different production technology requirements of high speed cutting of high strength and high hardness cast iron (steel), forged steel, stainless steel, titanium alloy, agluve alloy, magnesium alloy, aluminum alloy, powder metallurgy, nonmetal and other materials. Hard cutting tool is the leading product of numerical control processing tool, some countries have more than 90% turning tool and more than 55% of the milling tool are made of hard alloy and this trend is still increasing.

Grade Information:

|

Santon Grade |

Density(g/cm³) | TRS(n/mm²) | HRA | Performance & Applications | ISO Code |

| SK233-1 | 14.3-14.55 | 2800 | 91.5-92.5 | Extra fine substrate, high strength,good resistance to impact,vibration and wear,better red hardness,roughing and heavy milling for gray cast iron,nodular cast iron,creep grinding cast iron, non-ferrous metal,roughing for non-metallic materials, particularly for dry cutting applications. | K30 |

Company information:

The company takes an active response to the national call for the localization of smart intelligent manufacturing equipment. Its products are applied to the key industries such as aerospace, 5G, high-speed railway, large ships, wind power, automobile manufacturing, oil pipelines and heavy equipments. The carbide inserts especially designed for aerospace aluminum processing, 5G special optical fiber cutting, high-speed railway wheel online repair, large ship crankshaft milling, wind power gears, rotor machining, automobile engine cylinder heads, turbine shells and crankshaft milling, Petroleum pipeline processing are positioned at mid-to-high end level to replace import products, contributing to the localization of smart intelligent manufacturing equipment. With good reputation, excellent products and dedicated service, the company is deeply trusted and welcomed by users at home and abroad.

We have perfect carbide material analysis process and channels and strong ability of independent research and development of the material, the material (brand) is in the leading level in the trade, and made with special blade material (brand) is the most complete in the peer enterprises at home and abroad, material instead of foreign brands (brand) one of the most hard alloy production enterprises.

Certifications:

FAQ

Q.

Are

you

a

manufacturer

or

a

trading

company?

A.

We

are

a

professional

manufacturer

with

10

years

of

experience

of

producing

and

selling

carbiede

inserts.

Q.

What

is

your

main

products?

A.

Our

main

products

includes

cemented

carbide

plates,

strips,

blanks,

saw

tips,

geological

and

mining

bits,

brazed

tips,

indexable

carbide

inserts,

wear

parts,snow

plow

inserts,

tungsten

carbide

pins,

etc.

Q.

what's

the

payment

term?

A.

We

accept

Western

union,

Onetouch,

T/T,

and

L/C.

30%

T/T

deposit

and

70%

balance

before

shipment,

or

against

copy

of

BL,

or

L/C

at

sight.

Q.

What

about

your

delivery

time?

A.

Usually

it

will

take

about

25

-

30

days

for

production.But

for

new

molds,

the

lead

time

may

need

10days

more

to

open

molds.

If

you

need

the

goods

urgently,

we

could

try

to

push

for

and

shorten

the

delivery

time.

Q.

What

is

your

minimum

order

quantity(MOQ)?

A.

No

limit

for

MOQ.

For

non-standard

products,

mold

fee

need

to

be

paid,

but

can

be

refunded

later.

Q.

What

is

your

warranty?

A.

We

extend

a

100%

satisfaction

guarantee

on

all

items.

if

you’re

not

completely

satisfied

with

our

products

,we’ll

replace

them

or

refund

the

fee.

Q.Where

is

your

market?

A.

Our

products

are

popular

in

Germany,

America,

Mexico,

India,

Russia,

Indonesia,

Malaysia,

Bangladesh,

South

Africa,etc.

Contact information:

Chengdu

Santon

Cemented

Carbide

Co.,

Ltd

No.2618,4th

Konggang

Road,

Southwest

Airport

Economic

Development

Zone,

Chengdu

City,

Sichuan,P.R.

China.

Tel:

86-28-85739522

Fax:

86-28-85739559

sales Ginger mei

Whatsapp:+8618181940599

Email:export_2@santoncc.com