| Price | Negotiable |

| MOQ | 50 |

| Delivery Time | 15-25 working days |

| Brand | Santon |

| Place of Origin | China |

| Certification | ISO |

| Model Number | CUSTOMIZABLE |

| Packaging Details | Plastic boxes inside and cartons outside |

| Payment Terms | L/C,T/T,Western Union |

| Supply Ability | 2 million per month |

| Brand Name | Santon | Payment Terms | L/C,T/T,Western Union |

| Place of Origin | China | Price | Negotiable |

| Delivery Time | 15-25 working days | Minimum Order Quantity | 50 |

| Packaging Details | Plastic boxes inside and cartons outside | Model Number | CUSTOMIZABLE |

| Supply Ability | 2 million per month | Certification | ISO |

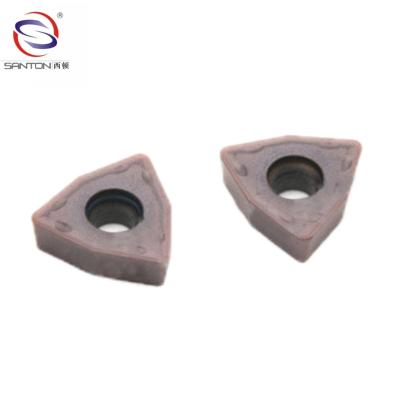

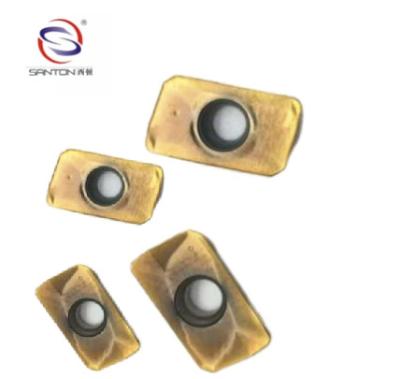

The CNC Carbide Inserts are precision-engineered cutting tools designed to deliver exceptional performance in a wide range of machining applications. Manufactured with high-quality materials and advanced technology, these inserts are ideal for turning, milling, and drilling operations on various metals and alloys. Whether you are working in automotive, aerospace, or general manufacturing, the CNC Carbide Inserts offer the durability and sharpness needed to achieve superior results consistently.

One of the standout features of these CNC Carbide Inserts is their status as Imported Universal cutting tools. The term "Imported Universal" signifies that these inserts are sourced from reputable international manufacturers known for their stringent quality standards and innovative designs. This ensures that each insert meets global benchmarks for toughness, wear resistance, and dimensional accuracy, making them reliable for both high-speed and heavy-duty machining tasks.

Thanks to their Imported Universal quality, these inserts boast a versatile design that fits a broad spectrum of CNC machines and tool holders. This universality simplifies inventory management and tooling setups for machine shops, reducing downtime and increasing productivity. The inserts are engineered with optimized geometries and coatings that enhance chip control and heat dissipation, further extending tool life and improving surface finish on workpieces.

The CNC Carbide Inserts are crafted from premium carbide material, which is known for its hardness and resistance to abrasion. This material composition allows the inserts to maintain sharp cutting edges longer than conventional tools, minimizing the frequency of tool changes and boosting operational efficiency. Additionally, their Imported Universal classification guarantees compatibility with various machining parameters and materials, from soft aluminum to hardened steels.

Another advantage of choosing these Imported Universal CNC Carbide Inserts lies in their precision manufacturing process. Utilizing advanced grinding and coating technologies, each insert achieves tight tolerances and a consistent cutting edge, ensuring repeatable performance and reduced scrap rates. The inserts are often coated with specialized layers such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Aluminum Oxide (Al2O3), which provide superior wear resistance and thermal stability during aggressive cutting conditions.

For users seeking flexibility, the CNC Carbide Inserts come in multiple shapes, sizes, and chipbreaker patterns to accommodate various machining strategies. Whether you require inserts for finishing, semi-finishing, or roughing operations, the Imported Universal range offers options tailored to meet specific cutting needs. This adaptability makes it easier to optimize cutting parameters, improve cycle times, and achieve better dimensional accuracy on complex parts.

In addition to performance benefits, these Imported Universal CNC Carbide Inserts also offer economic advantages. Their extended tool life and reliable performance reduce tooling costs and downtime, contributing to lower overall manufacturing expenses. Moreover, the consistency provided by imported universal standards means less variability in production quality, leading to higher customer satisfaction and fewer rework incidents.

Maintenance and handling of the CNC Carbide Inserts are straightforward due to their robust design and universal compatibility. Operators can quickly install and replace inserts without specialized tools or procedures, streamlining workflow and minimizing machine stoppages. The Imported Universal nature of these inserts ensures they integrate seamlessly with existing tooling systems, making upgrades or replacements hassle-free.

In summary, the CNC Carbide Inserts stand out as a premium choice for machining professionals who demand reliability, versatility, and high performance. Their Imported Universal quality guarantees that they meet rigorous international standards and can be used across a wide variety of CNC machines and applications. By investing in these inserts, manufacturers can enhance their machining capabilities, reduce costs, and achieve superior product quality consistently.

| Product Name | Imported Universal CNC Carbide Inserts |

| Material | High-Quality Tungsten Carbide |

| Grade | Imported Universal Grade |

| Shape | Square, Triangle, Round |

| Coating | Titanium Nitride (TiN) / Titanium Carbonitride (TiCN) |

| Application | Universal use for turning, milling, and drilling |

| Size Range | 5mm to 20mm |

| Tolerance | ±0.01mm |

| Hardness | HRA 91 ± 1 |

| Heat Resistance | Up to 1200°C |

| Origin | Imported Universal quality standard |

The Santon CNC Carbide Inserts are designed to meet the demanding needs of modern machining industries. As an Imported Universal solution, these inserts are highly versatile and compatible with a wide range of CNC machines, making them ideal for various application occasions and scenarios. Whether you are engaged in precision metal cutting, milling, turning, or drilling, the Santon CNC Carbide Inserts provide exceptional performance, durability, and reliability.

In manufacturing plants where high efficiency and accuracy are paramount, the Santon CNC Carbide Inserts are extensively used for machining hard materials such as stainless steel, cast iron, and non-ferrous metals. Their customizable model number allows for tailored specifications to suit specific machining requirements, ensuring optimal results across different projects. Thanks to the ISO certification, these inserts guarantee consistent quality and adherence to international standards, enhancing their appeal in global markets.

Due to their Imported Universal design, these inserts excel in automotive, aerospace, and heavy machinery industries where precision and long tool life are critical. The adaptability of the Santon CNC Carbide Inserts makes them suitable for both high-volume production lines and small batch jobs. With a supply ability of 2 million units per month, Santon can meet the demands of large-scale manufacturers and smaller workshops alike.

In addition to their industrial applications, these inserts are perfect for specialized tool shops and maintenance facilities that require fast turnaround times and reliable cutting tools. The minimum order quantity of 50 pieces makes it accessible for diverse customer needs, and the negotiable price coupled with flexible payment terms such as L/C, T/T, and Western Union facilitates smooth procurement processes.

The delivery time of 15-25 working days ensures timely availability, while the packaging details—plastic boxes inside and cartons outside—provide secure transportation and storage. Originating from China, these Santon CNC Carbide Inserts combine cost-effectiveness with world-class quality, making them a preferred choice for CNC machining applications globally.

Overall, the Imported Universal nature of the Santon CNC Carbide Inserts allows them to be seamlessly integrated into various machining setups, providing superior cutting performance and operational efficiency in diverse industrial scenarios.

Our CNC Carbide Inserts are engineered to deliver high precision and durability for a wide range of machining applications. To ensure optimal performance and longevity of your inserts, please follow the recommended usage guidelines and maintenance procedures provided in the product manual.

If you encounter any issues with your CNC Carbide Inserts, our technical support team is available to assist you with troubleshooting, product selection, and application advice. We are committed to providing prompt and effective solutions to maximize your machining efficiency.

For replacement parts, warranty information, and further technical documentation, please refer to the support section on our website. Regular updates and detailed product data sheets are also available to help you stay informed about the latest advancements and best practices in CNC machining.

We encourage customers to provide feedback and share their experiences to help us continually improve our products and services. Your satisfaction and success are our top priorities.

Each CNC Carbide Insert is carefully packaged to ensure maximum protection during transit. The inserts are securely placed in sturdy, cushioned containers to prevent any damage or displacement. Our packaging materials are designed to withstand shipping stresses and maintain product integrity.

For shipping, we use reliable carriers with tracking options to guarantee timely and safe delivery. Orders are processed promptly and dispatched with appropriate labeling and documentation to facilitate smooth customs clearance and delivery. Whether shipping domestically or internationally, customer satisfaction and product quality are our top priorities.

Q1: What brand manufactures these CNC Carbide Inserts?

A1: These CNC Carbide Inserts are manufactured by the brand Santon.

Q2: Can the model number of the CNC Carbide Inserts be customized?

A2: Yes, the model number is customizable to meet your specific requirements.

Q3: What is the minimum order quantity for these inserts?

A3: The minimum order quantity is 50 pieces.

Q4: What certifications do these CNC Carbide Inserts have?

A4: These inserts are ISO certified, ensuring high quality and reliability.

Q5: What payment methods are accepted for purchasing these inserts?

A5: We accept payments via L/C (Letter of Credit), T/T (Telegraphic Transfer), and Western Union.

Q6: What is the typical delivery time after placing an order?

A6: The delivery time is usually between 15 to 25 working days.

Q7: How are the CNC Carbide Inserts packaged for shipment?

A7: The inserts are packaged in plastic boxes inside and cartons outside to ensure safe delivery.

Q8: Where are these CNC Carbide Inserts manufactured?

A8: They are manufactured in China.

Q9: What is the monthly supply capacity for these inserts?

A9: The supply ability is up to 2 million pieces per month.

Q10: Is the price fixed or negotiable?

A10: The price is negotiable depending on your order quantity and specifications.