| Price | $30000-$60000/set |

| MOQ | 1 SET |

| Delivery Time | 2 months |

| Brand | HYDEB |

| Place of Origin | Shandong, China |

| Certification | CE certificate, ISO |

| Model Number | LDU-II |

| Packaging Details | Wooden box |

| Payment Terms | By T/T |

| Supply Ability | 1000 sets/ year |

| Place of Origin | Shandong, China | Packaging Details | Wooden box |

| Product Name | Molten Aluminum Launder Type Double Graphite Rotor In-Line Rotory Degassing Equipment | Model Number | LDU-II |

| Supply Ability | 1000 sets/ year | Certification | CE certificate, ISO |

| MOQ | 1 Set | Colour | Yellow & Siliver |

| Brand Name | HYDEB | Payment Terms | By T/T |

| Degassing Efficient | Hydrogen Less Than 0.12ml/100g-Al | Price | $30000-$60000/set |

| Delivery Time | 2 months | Rotor material | Graphite |

| Minimum Order Quantity | 1 SET | Application | on line Purity molten aluminum |

| Power | < 45KW |

Molten Aluminum Launder Type Double Graphite Rotor In-Line Rotory Degassing Equipment

Molten Aluminum Box type Double/Two Graphite Rotor in-line rotory degassing Equipment

1. In-line Rotory Degassing Equipment Description

•

The

LDU

has

higher

degassing

efficiency

because

degassing

rotors

are

mounted

between

the

melting

furnace

and

casting

machine

in

the

length

direction

of

the

launder

and

the

degassing

zone

is

partitioned

into

several

parts

for

multilevel

in-line

degassing.

The

number

of

rotors

depends

on

the

flow

rate

of

molten

aluminum

2. In-line Rotory Degassing Equipment Mainly Specification

| Items | Parameters |

| Maximum temperature of molten aluminum | 750℃ |

| Launder shell surface temperature | ≤60℃ |

| Launder lining life | ≥12 months |

| Rotor speed | 100-600rpm |

| Inert gases | High-purity N2, high-purity Ar |

| Degassing efficiency |

When it is not greater than the maximum flow rate, the inlet hydrogen content is ≤0.30ml / 100gAl, when the aluminum liquid is 700-740 ℃, the hydrogen content after degassing is ≤0.22ml / 100g -Degassing efficiency≥35% when hydrogen content at the inlet>0.30ml/100g-Al. |

| Power supply | 380V AC 50Hz, ≤10KVA |

4. In-line Rotory Degassing Equipment Models

| No. Of Rotor | 1 | 2 | 3 | 4 |

| Type | LDU-I | LDU-II | LDU-III |

LDU-IV |

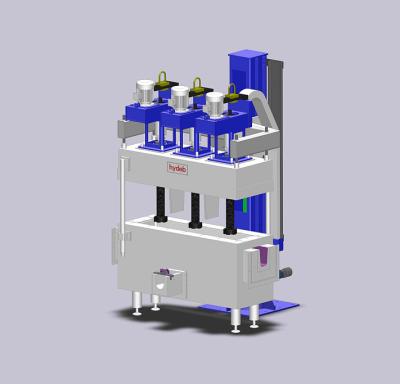

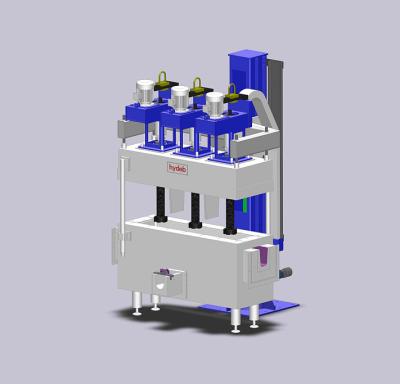

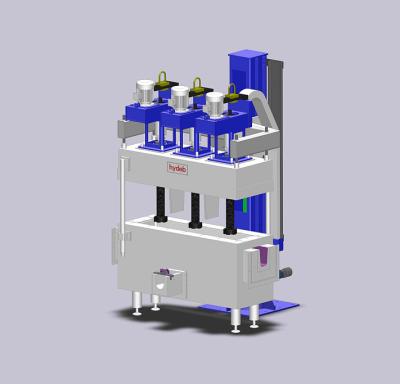

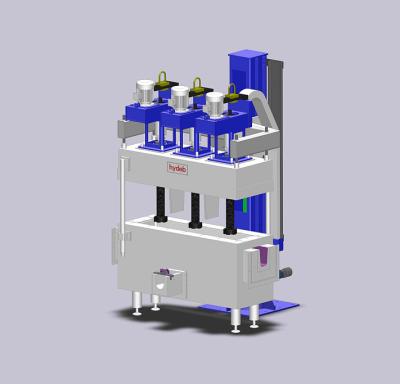

5. In-line Rotory Degassing Equipment Pictures

6. Company Profile

-- Established in January 2003, and now has 56 employees

-- Sales of 50 million RMB in 2021

-- Focus on one industry -- "aluminum casting"

-- Has a complete product line of aluminum casting equipment, all products are independent research

and development, manufacturing

-- aluminum melting and holding, transportation, ladle preheating, aluminum liquid refining, aluminum liquid

hydrogen measurement, until aluminum solution aging treatment equipment

7. FRQ

Q1:

I

know

nothing

about

this

in-line

rotory

degassing

equipment,

what

kind

of

in-line

rotory

degassing

equipment

I

should

choose?

Very

easy.

We

will

email

you

an

inquiry

form

for

making

sure

your

real

need.

Or

just

tell

us

what

you

want

to

do

by

using

this

machine,

then

let

us

give

you

perfect

solutions

and

suggestions.

Q2:

When

I

get

this

in-line

rotory

degassing

equipment,

but

I

don’t

know

how

to

use

it.

What

should

I

do?

We

will

send

pictures

or

video

and

English

manual

with

the

machine.

If

you

still

have

some

doubts,

we

can

talk

by

Telephone/

Skype

/

Whatsapp

/

Weichat/

E-mail.

Q3:

If

some

problems

happen

to

this

in-line

rotory

degassing

equipment

during

warranty

period,

what

should

I

do?

We

will

supply

free

parts

during

machine

warranty

period

if

machine

have

some

problems

(except

spare

parts).

While

we

also

supply

free

life

long

after-sales

service.

So

any

doubts,

just

let

us

know,

we

will

give

you

solutions.