| Price | negotiable |

| MOQ | 1 set |

| Delivery Time | For detailed talk |

| Brand | Chuzhou HH non-woven |

| Place of Origin | Chuzhou China |

| Certification | CE |

| Model Number | HH Meltblown |

| Packaging Details | wooden case |

| Payment Terms | L/C, T/T |

| Supply Ability | For detailed talk |

| Place of Origin | Chuzhou China | Motor | Siemens AC |

| bearing | TWB SKF | Packaging Details | wooden case |

| Product | 1600 M Meltblown Nonwoven Fabric Machine | Model Number | HH Meltblown |

| Supply Ability | For detailed talk | Melt die | ENKA |

| Certification | CE | Brand Name | Chuzhou HH non-woven |

| Payment Terms | L/C, T/T | Price | negotiable |

| Delivery Time | For detailed talk | Filament denier | 1.6 - 4 um |

| Minimum Order Quantity | 1 set | daily output | 3 ton |

| warranty | one year free warranty and long time service | Certificate | CE |

PP

Meltblown

Nonwoven

Fabric

Making

Machine

for

Mask

Filter

Fabric

Melt blown cloth is mainly used to provide raw materials for N9, N95 and n99 masks. In other words, melt blown cloth is the core material of masks, because masks produced with melt blown cloth can play a good filtering role. Melt blown cloth is made of polypropylene as the main raw material.

| PROJECT |

MELT

BLOWN

NONWOVEN

FABRIC

PRODUCTION

LINE |

||

|

WIDTH |

1600MM | ||

|

MACHINE

SPEED |

≦70

M/MIN |

||

|

MODEL |

HHM-PP1600 | ||

|

CAPACITY |

2-3

T/DAY;(calculation

based

on

fabric

18gsm,

width

at

1600mm) |

||

|

FILAMENT

DENIER 纤维细度 |

1.6~4μm |

||

|

FABRIC

WEIGHT 克重范围 |

18~300GSM | ||

|

RAW

MATERIAL 原料级别 |

100%

POLYPROPYLENE

GRANULE

FIBER

GRADE; MFI 800~1600 FOR MEL TBLOWN 100%丙纶全新料-纤维级;熔喷-熔融指数800~1600 |

||

|

PLANT

SIZE |

6m*8m*7m | ||

HHM

1600

m

meltblown

fabric

making

line

date

| Width | 1600 M |

| Gsm | 9 - 250 gsm |

| Output per day | 4 - 6Ton |

| Machine Speed | ≦70 m / min |

| Transformer | ≈ 600 KVA |

| Power Consumption | 3000º - 3500º / Ton |

| Machine Size | 18 * 8 *12 M |

| Model | Effective Width | Weight Range | Output per day | Machine speed | Tranformer | Power consumption | Machine Size |

| HHM-1.6M | 1.6M | 15-300G/M2 | 2-3Ton | ≦10-70m/min | ≈600KVA | 3000º-3500º/Ton | 18M*10M*10M |

| HHM-2.4M | 2.4M | 15-300G/M2 | 3-4Ton | ≦10-70m/min | ≈800KVA | 3000º-3500º/Ton | 18M*11M*10M |

| HHM-3.2M | 3.2M | 15-300G/M2 | 4.5-5Ton | ≦10-70m/min | ≈1000KVA | 3000º-3500º/Ton | 18M*13M*10M |

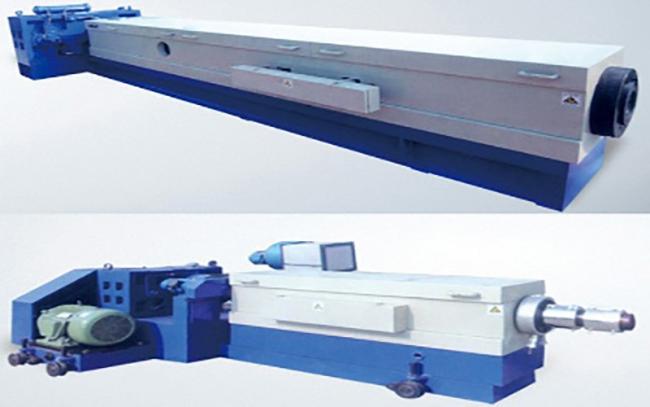

Image of Non woven fabric making

Parts

of

Melt

blown

nonwoven

fabric

production

line:

Main

extruder→filter→Metering

pump→Air

heating

system→Melt

blown

sprayer

(ENKA

sprayer)→Web

former→Winder→Slitter

Melt

blown

process

and

technical

flow

chart:

Raw

material

→Melting→Filtering→Measureing→Air

heating→Spraying→Web

forming→Winding→Cutting→Final

product

Main

machine

parts

introduce

| Maximum temperature | 300 ℃ |

| Max. Output | 200 kg / h |

| Heating zone | 8 tod |

| Perforated length | 3,350 mm |

| HPI | 40 |

| Number of holes | 5,276 |

| 1 Set L/D | 10 |

| Capillary diameter | 0.3mm |

| Capillary length | 3,600mm |

| Aperture (1pc) | 90 300 kg / h |

| The screw L/D of the main extruder | 30:1 |

| The screw L/D of the ancillary extruder | 15:1 |

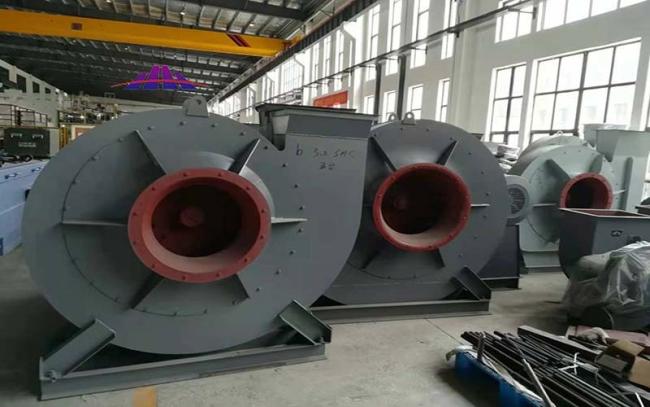

Air

heater

Heating

power:

220KW-240KW

Material

of

tank

and

pipeline:

stainless

steel

304

Insulation

form:

stainless

steel

seal

outside

the

insulation

layer

Air

Blower

It

is

used

to

pump,

exhaust

gas,

and

to

compress

the

gas,

and

convert

the

energy

input

into

the

kinetic

energy

and

potential

energy

of

the

gas

in

order

to

increase

the

unit

energy

of

the

gas.

Precisely

CNC

center

ensure

processing

accuracy

Exhibition

show

Packaging

Details

Nude

packing

,

wooden

case

is

optional.

case

packing:Carding

machine,

lapper

and

electric

boxes

wooden

case

packaged.

Other

machines

nude

packaging.

FAQ:

1.How

can

i

know

your

machine

has

good

quality?

You

can

visit

our

company

and

we

will

see

many

machines

in

China,because

we

also

have

many

customers

from

local

market.

2.What

is

the

delivery

time

for

nonwoven

machines

as

usual?

We

need

3-6

month

to

make

your

order.

3.Will

you

inspect

my

order

before

shipping?

We

accept

SGS

inspection

service

and

buyer

own

inspect

it,we

will

pay

all

expense

for

buyer

visiting.

4.How

is

your

after-sale

service

and

warranty?

we

provide

12

month

warranty

and

free

door

to

door

engineering

service

in

the

period.

Free

spare

parts

replacement

and

online

technical

support.

5.How

long

time

for

machine

installation?

It

takes

30-60

days

for

machine

installation

as

usual.