Type K N E J T S R B Mineral Insulated Thermocouple Cable

Accurate temperature measurement solution for industrial settings with various thermocouple types and configurations.

Product Specifications

Thermocouple Types: K, N, E, J, T, S, R, B

Place of Origin: Zhejiang, China

Accuracy Classes: I (0.4%t), II (0.75%t), III (1.5%t)

Core Number: 2, 3, 4, 6

Conductor Materials: Nickel, Copper

Insulation: 99.6% high purity Magnesium Oxide (MgO)

Certifications: ISO9001, IATF16949, CE

Application: Connection with thermocouple and instrument machines

Sheath Materials: 0Cr18Ni10Ti, SS304, SS316L, SS316, Copper

Sheath Diameter: φ3.0, φ4.0, φ6.0, φ8.0 mm

Temperature Specifications by Sheath Type

| Product Name |

Code |

Type |

Sheath Material |

Outside Diameter |

Temperature (°C) |

| NiCr-NiSi /NiCr-NiAl | KK | K | SS304 SS316 | 0.5-1.0 | 400 |

| | | | 1.5-3.2 | 600 |

| | | | 4.0-8.0 | 800 |

| | | SS310 Inconel600 | 0.5-1.0 | 500 |

| | | | 1.5-3.2 | 800 |

| | | | 4.0-6.4 | 900 |

| | | | 8.0-12.7 | 1000 |

| NiCrSi-NiSi | NK | N | SS304 SS316 | 0.5-1.0 | 400 |

| | | | 1.5-3.2 | 600 |

| | | | 4.0-8.0 | 800 |

| | | SS310 Inconel600 | 0.5-1.0 | 500 |

| | | | 1.5-3.2 | 800 |

| | | | 4.0-6.4 | 900 |

| | | | 8.0-12.7 | 1000 |

| NiCr-Konstantan | EK | E | SS304 SS316 | 0.5-1.0 | 400 |

| | | | 1.5-3.2 | 600 |

| | | | 4.0-8.0 | 800 |

| Fe-Konstantan | JK | J | SS304 SS316 | 0.5-1.0 | 400 |

| | | | 1.5-3.2 | 600 |

| | | | 4.0-8.0 | 800 |

| Cu-Konstantan | TK | T | SS304 SS316 | 0.5-1.0 | 400 |

| | | | 1.5-3.2 | 600 |

| | | | 4.0-8.0 | 800 |

| RhPt10-Ph | SK | S | Inconel600 | 6.0-12.7 | 1100 |

Note: Different temperature measuring media and service conditions impact service life and temperature range. Table data is for reference only.

Accuracy Specifications

| Type |

Class I |

Class II |

| K | ±1.5℃ (-40~375℃)

±0.4% (375℃-1000℃) | ±2.5℃ (-40~375℃)

±0.75% (375℃-1000℃) |

| N | ±1.5℃ (-40~375℃)

±0.4% (375℃-1000℃) | ±2.5℃ (-40~375℃)

±0.75% (375℃-1000℃) |

| E | ±1.5℃ (-40~375℃)

±0.4% (375℃-800℃) | ±2.5℃ (-40~375℃)

±0.75% (375℃-800℃) |

| J | ±1.5℃ (-40~375℃)

±0.4% (375℃-800℃) | ±2.5℃ (-40~375℃)

±0.75% (375℃-800℃) |

| T | ±0.5℃ (-40~125℃)

±0.4% (125℃-350℃) | ±1.0℃ (-40~125℃)

±0.75% (125℃-350℃) |

| S | ±1.0℃ (0-1100℃) | ±1.5℃ (0-1100℃) |

Product Features

- Available in sizes from 0.5mm to 4.0mm, measuring temperatures up to 1200°C

- Conductor options: solid or stranded based on application requirements

- Mineral insulation provides excellent electrical insulation and mechanical protection

- Stainless steel sheath offers corrosion resistance and high-temperature durability

- Multiple connector types: screw, plug, and socket configurations

- High reliability and accuracy for demanding industrial applications

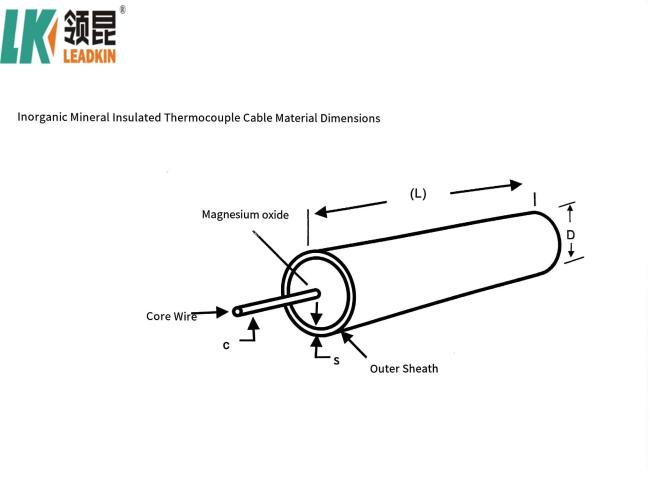

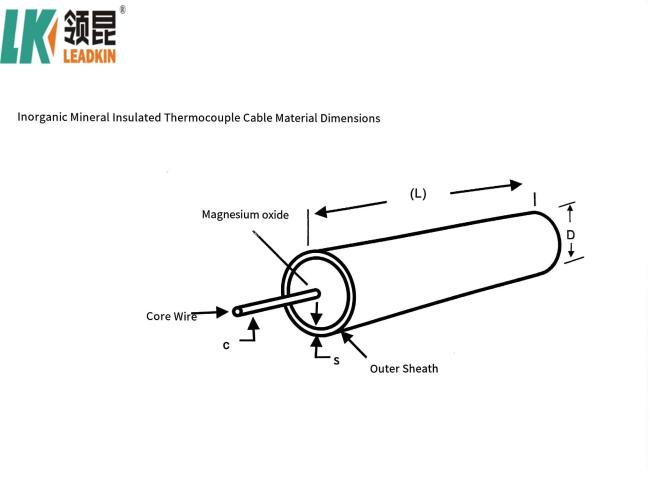

What is Mineral Insulated (MI) Cable?

Mineral Insulated cables feature conductors enclosed by a metal jacket and insulated with hard-packed Magnesium Oxide (MgO). This construction provides exceptional electrical isolation, physical protection, and high-temperature capability in harsh environments.

- Construction: Copper or thermocouple wires inside copper, stainless steel, or Inconel sheath

- Insulation: Magnesium oxide provides chemical and physical stability at high temperatures

- Configurations: Available with 1, 2, or 3 pairs of conductors, plus custom configurations

- Applications: Heat treating metals, solid waste incinerators, sintering powdered metals, ceramic firing, furnaces, and energy plants

Product Images

Company Overview

Main Products

Packaging

We use heat shrink tubing and plastic film to ensure high insulated resistance. Each coil cable includes marking notes, pass card, and test report.

Production Capabilities

We maintain high-quality professional products with advanced production lines and equipment. All products comply with international quality standards and are continuously improved to meet market demands.

Support & Services

- Selection guidance for thermocouple type, sheath material, and insulation material

- Assistance with cable installation and maintenance

- Troubleshooting and problem-solving

- Repair and warranty services

Ordering Process

- Accurate quotation provided

- Confirmation of price, trade terms, lead time, and payment terms

- Proforma Invoice with company seal

- Customer arranges deposit payment

- Production updates with photos

- Balance payment and shipment

- Tracking information provided

- Quality feedback and continuous improvement