| Price | 500-1000 USD PER TON |

| MOQ | 100KG |

| Delivery Time | 5-10Days after confirming order |

| Brand | TISCO |

| Place of Origin | Mainland China |

| Certification | SGS ISO ROHS |

| Model Number | Stainless Steel Sheet |

| Packaging Details | Standard waterproof package |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 800TONS PER MONTH |

| Place of Origin | Mainland China | Packaging Details | Standard waterproof package |

| Standard | ASTM,JIS,AISI,EN,GB | Grade | 300 Series,400 Series,200 Series,201/202/304 /304L/316/316L321/310s/410/420/430/440/439ect,Stainless steel |

| Model Number | Stainless Steel Sheet | Supply Ability | 800TONS PER MONTH |

| Certification | SGS ISO ROHS | Brand Name | TISCO |

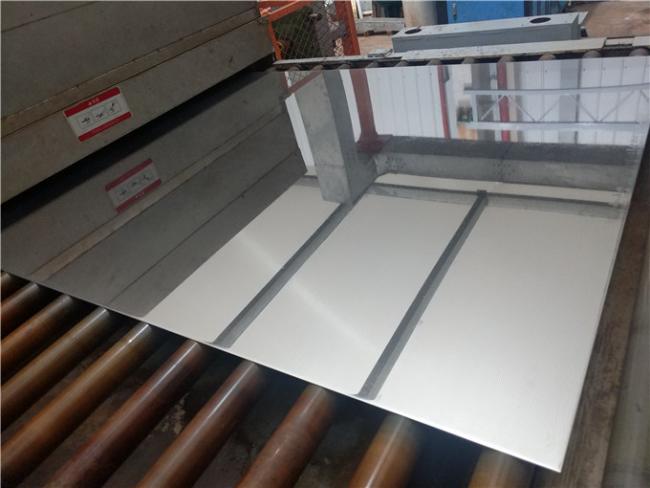

| Payment Terms | L/C, T/T, Western Union | Surface finish | 2B/BA/HAIRLINE/8K/NO.4/No.1 Or customize,2B/BA/HAIRLINE/8K/NO.4,2B/NO.1/BA/HL/NO.4/8K/Embossed |

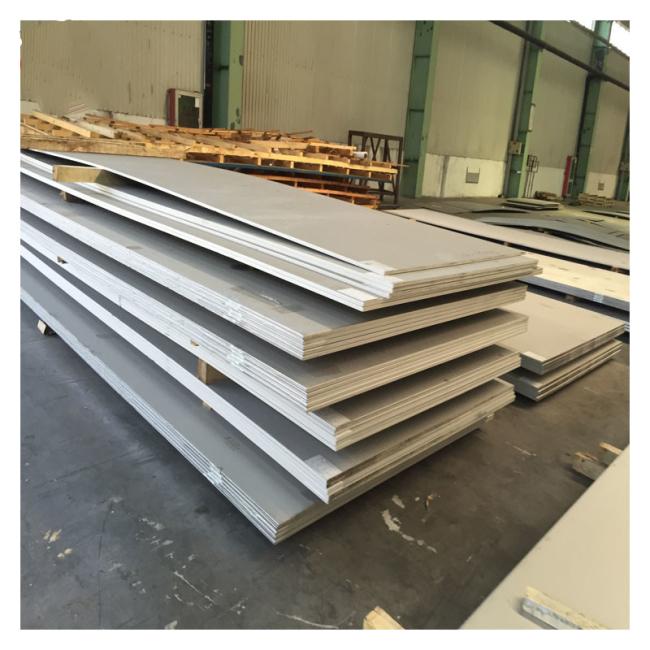

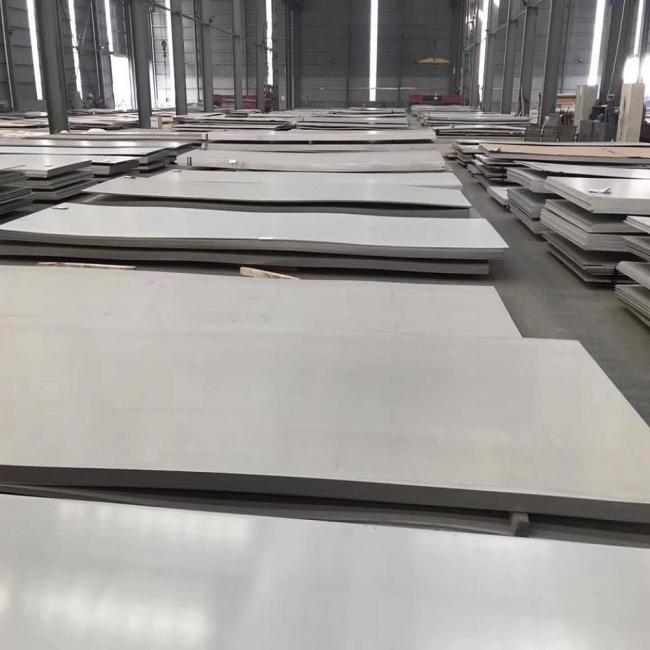

| Type | Plate,Coil,stainless steel sheet | Price | 500-1000 USD PER TON |

| Delivery Time | 5-10Days after confirming order | Length | Customer's Request,1000-6000mm or Customer's Requirement,2440mm,customer required,2438/3000/6000 |

| Product name | Stainless Steel Sheet Coil | Minimum Order Quantity | 100KG |

| Application | Construction,Kitchenware,Decoration,chemical,Industry | Width | 1000-2000mm,or as required,20mm-1250mm,1219/1250/1500,7mm-2000mm |

ASTM 904L Stainless steel sheet punch 310S Heat resistant steel plate laser cutting manufacturer

|

Grade

|

201,202,301,304,304L,316L,310,321,409,410,420,430,904l,C-276

|

|||

|

Standard

|

JIS,AISI,ASTM,DIN,EN,GB

|

|||

|

Length

|

1000-8000mm

or

customized

|

|||

|

Width

|

50-2000mm

|

|||

|

Thickness

|

0.3-100mm

|

|||

|

Surface

|

2B/BA/NO.1/NO.4/8K/HL

|

|||

|

Application

|

Building.bridge,hotel,factory,fan

etc

|

|||

|

Certificate

|

ISO9001,SGS,TUV,BV

etc

|

|||

|

Grade

|

201,202,301,304,304L,316L,310,321,409,410,420,430,904l,C-276

|

|||

|

Standard

|

JIS,AISI,ASTM,DIN,EN,GB

|

|||

|

Length

|

1000-8000mm

or

customized

|

|||

|

Width

|

50-2000mm

|

|||

|

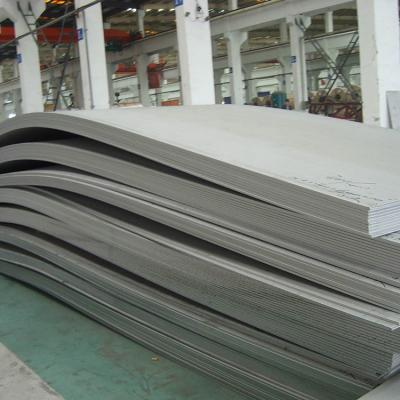

Thickness

|

0.3-100mm

|

|||

|

Surface

|

2B/BA/NO.1/NO.4/8K/HL

|

|||

|

Application

|

Building.bridge,hotel,factory,fan

etc

|

|||

|

Certificate

|

ISO9001,SGS,TUV,BV

etc

|

|||

|

Finish

|

Thickness

|

Characteristics

|

Applications

|

|

2B

|

0.3-6.0mm

|

Finished

by

heat

treatment

|

General

application

|

|

BA(Bright

annealed)

|

0.5-2.0mm

|

Bright

heat

treatment

|

Kitchen

utensil

|

|

NO.1

|

3.0-50.0mm

|

Finished

by

hot

rolled

|

Chemical

industry

|

|

NO.4

|

0.4-3.0mm

|

Ink

short

brush

|

Milk

&

food

processing

|

|

8K

|

0.4-3.0mm

|

Mirror

finish

|

Lift

and

hall

|

specifications:

Thickness

:

Cold

rolled(0.3mm-6.0mm);

Hot

rolled:(3.0mm

-

130mm)

Width

:

1000mm/1219mm/1250mm/1500mm/1800mm/2000mm

or

as

needed

Length

:

1000mm/2000mm/2440mm/3000mm/6000mm/12000mm

or

as

needed.

| Steel grade | ASTM | Mechinical Spefication | ||

| Rm Mpa | Y.S.(Mpa) | A5 | ||

| 201 | 201 | ≥520 | ≥275 | ≥40 |

| 1Cr17Ni7 | ≥520 | ≥205 | ≥40 | |

| 301 | 301 | ≥520 | ≥205 | ≥40 |

| 1Cr18Ni9 | ≥520 | ≥205 | ≥40 | |

| 0Cr18Ni9 | ≥520 | ≥205 | ≥40 | |

| 304 | 304 | ≥515 | ≥205 | ≥30 |

| 00Cr19Ni10 | ≥480 | ≥175 | ≥40 | |

| 304L | 304L | ≥485 | ≥170 | ≥30 |

| 309S | 309S | ≥520 | ≥205 | ≥40 |

| 0Cr25Ni20 | ≥520 | ≥205 | ≥40 | |

| 310S | 310S | ≥520 | ≥205 | ≥40 |

| 0Cr17Ni12Mo2 | ≥520 | ≥205 | ≥40 | |

| 316 | 316 | ≥515 | ≥205 | ≥30 |

| 00Cr17Ni14Mo2 | ≥480 | ≥175 | ≥40 | |

| 316L | 316L | ≥485 | ≥170 | ≥30 |

| 316Ti | 316Ti | ≥515 | ≥205 | ≥30 |

| 0Cr19Ni13Mo3 | ≥520 | ≥205 | ≥40 | |

| 00Cr19Ni13Mo3 | ≥480 | ≥177 | ≥40 | |

| 317L | 317L | ≥480 | ≥176 | ≥40 |

| 0Cr18Ni10Ti | ≥520 | ≥205 | ≥40 | |

| 321 | 321 | ≥515 | ≥205 | ≥30 |

| 409L | ≥360 | ≥175 | ≥25 | |

| 410 | 410 | ≥440 | ≥205 | ≥20 |

| 430 | 430 | ≥450 | ≥205 | ≥22 |

| 444 | 444 | ≥480 | ≥310 | ≥30 |

| 410S | ≥420 | ≥290 | ≥33 | |

| 2205/S31803/F51 | 2205 | ≥450 | ≥620 | ≥15 |

| 2507/S32750/F53 | 2507 | ≥550 | ≥800 | ≥25 |

| 630 | ≥520 | ≥785 | ≥18 | |

| 904L/N08904 | ≥490 | ≥216 | ≥35 | |

Regular cleaning and maintenance

Pay

attention

to

prevent

the

occurrence

of

the

phenomenon

of

surface

scratches

Use

soap,

weak

detergent

or

warm

water

to

remove

surface

dust,

dirt

In

addition

to

the

surface

of

the

binder

with

alcohol

or

an

organic

solvent

(benzene)

Use

neutral

detergent

or

ammonia

solution

in

addition

to

surface

oil

With

10%

nitric

acid

or

abrasive

detergent

in

addition

to

the

surface

of

the

embroider

caused

by

the

dirt.