| Price | Negotiable |

| MOQ | 100 meters |

| Delivery Time | 10-30 days |

| Brand | UCER |

| Place of Origin | China |

| Certification | Enterprise credit rating AAA |

| Model Number | ST630/ST800/ST1000/ST1250/ST1600/ST2000 |

| Packaging Details | Iron packing, iron frame or other |

| Payment Terms | L/C, D/P, T/T |

| Supply Ability | 10000 per month |

| Usage | Conveyor | Place of Origin | China |

| Warranty | 1 Year | Packaging Details | Iron packing, iron frame or other |

| Color | Black | Model Number | ST630/ST800/ST1000/ST1250/ST1600/ST2000 |

| Supply Ability | 10000 per month | Certification | Enterprise credit rating AAA |

| Brand Name | UCER | Payment Terms | L/C, D/P, T/T |

| Thickness | 6mm-30mm | Price | Negotiable |

| Delivery Time | 10-30 days | Length | 10000mm |

| Minimum Order Quantity | 100 meters | Standard or nonstandard | Standard |

| Model | ST1000 | Width | 800mm |

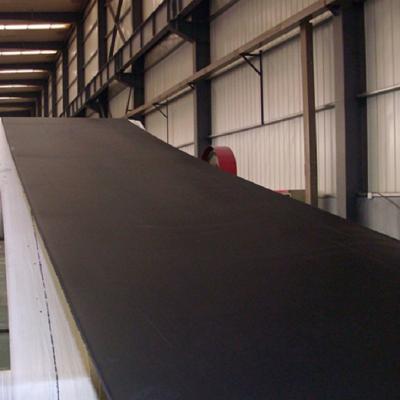

High temperature resistant conveyor belt ST1000 Special Conveyor Belts

High temperature resistant conveyor belt is a conveyor belt used to transport high temperature materials.

1. Classification

Heat-resistant

conveyor

belts

are

divided

into

ordinary

heat-resistant

belts

and

strong

heat-resistant

conveyor

belts.

The

strength

layer

of

ordinary

heat-resistant

belts

is

polyester

cotton

canvas

(CC56),

and

the

strength

layer

of

strong

heat-resistant

belts

is

EP

(specifically,

it

is

divided

into

EP100

and

EP150.

EP200,

EP250,

EP300,

EP350,

EP400,

EP450,

EP500,

etc.).

2. Use matters needing attention

With

the

popularity

of

conveyor

belts

in

industrial

production,

multiple

varieties,

high

performance,

light

weight,

multi-function,

and

long

life

are

several

aspects

that

manufacturers

pay

attention

to.

In

industrial

production,

the

correct

use

of

conveyor

belts

is

particularly

important.

The

following

items

should

be

paid

attention

to

in

the

use

of

conveyor

belts:

1)

Avoid

the

roller

being

covered

by

the

material,

causing

the

rotation

failure,

prevent

the

leakage

of

the

material

from

getting

stuck

between

the

roller

and

the

belt,

pay

attention

to

the

lubrication

of

the

movable

part

of

the

conveyor

belt,

but

do

not

oil

the

conveyor

belt;

2)

Prevent

the

conveyor

belt

from

starting

under

load;

3)

If

the

conveyor

belt

deviates,

measures

should

be

taken

to

correct

it

in

time;

4)

When

the

conveyor

belt

is

found

to

be

partially

damaged,

use

artificial

cotton

to

repair

it

i

<

| Variety | Standards and main indicators |

| Ordinary steel cord conveyor belt | GB/T9770-2001 |

| Flame-retardant steel cord conveyor belt | MT668-1997 |

| General flame-retardant steel cord conveyor belt | MT668-1997 |

| Heat-resistant steel cord conveyor belt | HG2297-92 |

| Wear-resistant steel cord conveyor belt | Shaoboer wear amount ≤90mm 3 |

| Acid, alkali and oil resistant steel cord conveyor belt |

HG4-846 HG4-846 |

| Cold-resistant steel cord conveyor belt | Brittleness temperature -40℃ |