| Price | Negotiable |

| MOQ | 100 meters |

| Delivery Time | 10-30 days |

| Brand | UCER |

| Place of Origin | China |

| Certification | Enterprise credit rating AAA |

| Model Number | ST630/ST800/ST1000/ST1250/ST1600/ST2000 |

| Packaging Details | Iron packing, iron frame or other |

| Payment Terms | L/C, D/P, T/T |

| Supply Ability | 10000 per month |

| The minimum working temperature | -60℃ | Usage | Conveyor |

| Place of Origin | China | Warranty | 12 month |

| Packaging Details | Iron packing, iron frame or other | Color | Black |

| Material feature | Heat Resistant | Model Number | ST630/ST800/ST1000/ST1250/ST1600/ST2000 |

| Supply Ability | 10000 per month | Certification | Enterprise credit rating AAA |

| Brand Name | UCER | Payment Terms | L/C, D/P, T/T |

| Price | Negotiable | Delivery Time | 10-30 days |

| Length | 2100mm | Minimum Order Quantity | 100 meters |

| Model | ST630/ST800 | Performance | GB9770 |

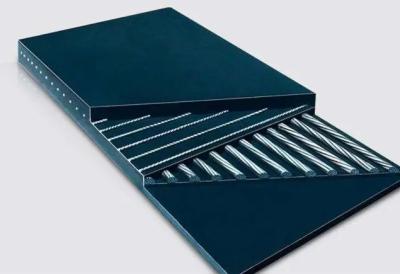

Steel cord conveyor belt ST800 Wire Rope Conveyor Belt

Wire rope conveyor belt is a rubber conveyor belt with steel wire as the skeleton. It has the advantages of high tensile strength, good impact resistance, long life, low elongation, good trough forming, and good flexural resistance. It is suitable for long-distance, long-haul, and high-speed transportation of materials. The product is composed of core rubber, steel wire rope, covering layer and edge rubber.

1.

Purpose

Wire

rope

conveyor

belt

is

suitable

for

material

transportation

under

tear-proof

conditions

required

by

coal

mines,

mines,

ports,

electric

power,

metallurgy,

building

materials

and

other

industries.

It

can

be

used

for

long-distance,

large-span,

large-volume

and

high-speed

material

transportation.

2. The form of damage

There

are

many

forms

of

damage

to

the

wire

rope

conveyor

belt,

mainly:

serious

wear

on

the

rubber

surface;

ripped

edges;

tearing.

Among

them,

conveyor

belt

tearing

is

the

most

harmful

form

of

damage.

It

mainly

refers

to

the

longitudinal

tearing

of

the

conveyor

belt

caused

by

the

sharp

impurities

in

the

conveying

material

being

inserted

into

the

conveyor

belt

or

the

steel

wire

in

the

conveyor

belt

is

drawn

out.

Although

the

tearing

of

the

conveyor

belt

is

an

accidental

damage,

it

is

very

destructive.

If

it

is

not

controlled

in

time,

it

will

cause

the

entire

conveyor

belt

to

tear

(accidents

of

tearing

the

conveyor

belt

of

thousands

of

meters

occur

from

time

to

time

in

the

port),

which

will

cause

production

shutdown

,

Bringing

huge

direct

and

indirect

economic

losses

to

the

port.

Therefore,

the

protection

and

detection

of

the

tearing

of

the

conveyor

belt

have

always

been

paid

attention

to

by

the

conveyor

belt

manufacturers

and

users.

At

the

same

time,

the

relevant

national

standards

also

require

that

the

conveyor

belt

should

be

installed

to

prevent

longitudinal

tearing

and

tearing

detection

devices.

<

| Variety | Standards and main indicators |

| Ordinary steel cord conveyor belt | GB/T9770-2001 |

| Flame-retardant steel cord conveyor belt | MT668-1997 |

| General flame-retardant steel cord conveyor belt | MT668-1997 |

| Heat-resistant steel cord conveyor belt | HG2297-92 |

| Wear-resistant steel cord conveyor belt | Shaoboer wear amount ≤90mm 3 |

| Acid, alkali and oil resistant steel cord conveyor belt |

HG4-846 HG4-846 |

| Cold-resistant steel cord conveyor belt | Brittleness temperature -40℃ |