| Price | Negotiable |

| MOQ | Negotiable |

| Delivery Time | 7-15 work days |

| Brand | EMT |

| Place of Origin | Jiangsu |

| Certification | Yes |

| Packaging Details | According to customer needs |

| Payment Terms | T/T, Western Union |

| Supply Ability | 50000PCS /Month |

| Model of production equipment | 1500T Magnesium alloy semi-solid injection molding machine | Place of Origin | Jiangsu |

| Packaging Details | According to customer needs | Material | Magnesium alloy |

| Supply Ability | 50000PCS /Month | Certification | Yes |

| Surface treatment | Powder coating, electroplating, oxide, anodization | Processing | CNC Turning, Milling parts, Dilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. |

| Brand Name | EMT | Payment Terms | T/T, Western Union |

| Technics | One piece,laser cut, bend, weld, stamp | feature | Customized |

| Price | Negotiable | Delivery Time | 7-15 work days |

| Minimum Order Quantity | Negotiable | Drawing Formats | PRO/E, Auto CAD, Solid Works, UG, CAD/ CAM / CAE, PDF |

| Application | Auto Parts | Diameter | standard |

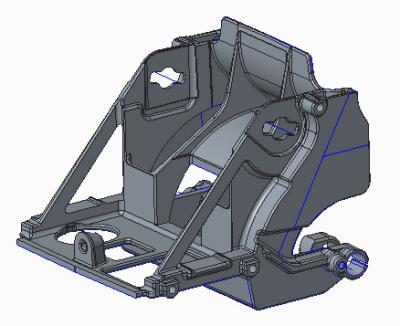

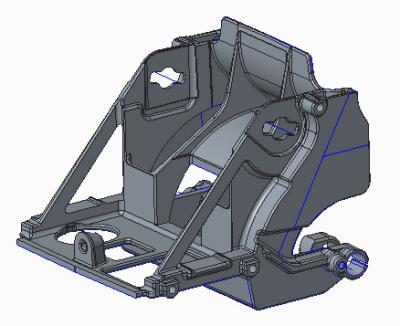

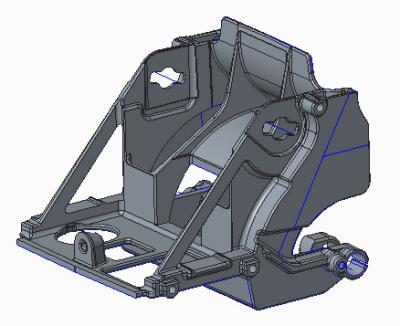

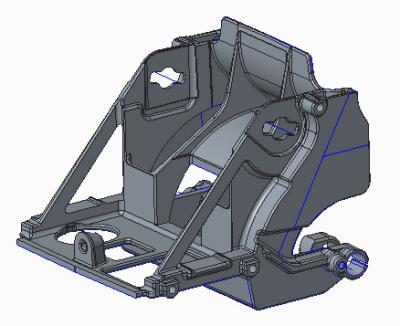

EMT 2000T Die Car Seat Frame Magnesium Metal Alloy

Advantage:

Automobile seat frame is another typical part that can be die-cast with magnesium alloy, because magnesium alloy has the characteristics of good formability, low density, good simplified structure effect, and also has the advantages of easy parts integration and improved earthquake resistance. German Mercedes Automobile Company uses AM series magnesium alloy seat frame, assembled by 5 magnesium alloy thick wall die casting parts, weighing only 8.5 kg, 11.5 kg lighter than the original steel frame, that is, 57.5% lighter, and then successfully developed only 2 kg seat frame, composed of a seat bottom frame and a seat back frame. Their wall thickness is only 2 mm to 4 mm and does not require deep mechanical cutting prior to assembly. The application of magnesium alloy seat frame greatly stimulates the development of magnesium application, substituting magnesium for steel and aluminum can achieve significant weight reduction, energy saving and emission reduction, and improve the impact resistance of the car.

Advantage:

FAQ:

1. Q:Are you a factory or a trading company?

A:We are a factory which has been focus on Magnesium alloy deep processing lightweight field & semi-solid injection molding of Magnesium alloy for more than 16+ years.

2. Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control.

3. Q: Has the company established and implemented a standard procedure for purchasing contract review and approval?

A: Yes, with written standard procedures.

4. Q: Is there a procedure to conduct random product inspections after final packaging?

A: Yes, with clear standard and written inspection records.

5. Q: How can I get a quotation?

A: Please kindly send us following information 1) Product drawings by STEP/STP/PRT/PDF/IGS format etc. 2) Material, size and surface treatment request. 3) Required quantity. Normally,the quote will be offer in 1-6 hours. :)

6. Q: What is your payment terms?

A: T/T, Western Union, etc.