| Price | Negotiable |

| MOQ | Negotiable |

| Delivery Time | 7-15 work days |

| Brand | EMT |

| Place of Origin | CHINA |

| Certification | TS16949、IOS9001 |

| Packaging Details | According to customer needs |

| Payment Terms | T/T, Western Union |

| Supply Ability | 50000PCS /Month |

| Model of production equipment | 800T Magnesium alloy semi-solid injection molding machine | Place of Origin | CHINA |

| Testing Equipment | CMM / Tool microscope / multi-joint arm / Automatic height gauge / Manual height gauge / Dial gauge / Roughness measurement | Packaging Details | According to customer needs |

| Material | Magnesium alloy | Supply Ability | 50000PCS /Month |

| Certification | TS16949、IOS9001 | Surface treatment | Powder coating, electroplating, oxide, anodization |

| Processing | CNC Turning, Milling parts, Dilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. | Brand Name | EMT |

| Payment Terms | T/T, Western Union | Price | Negotiable |

| Delivery Time | 7-15 work days | Minimum Order Quantity | Negotiable |

| Drawing Formats | PRO/E, Auto CAD, Solid Works, UG, CAD/ CAM / CAE, PDF |

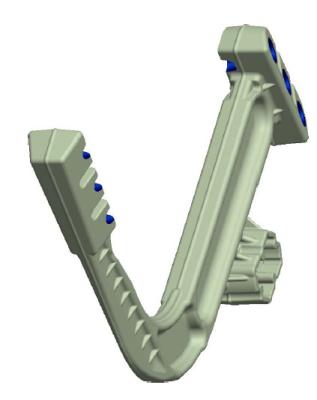

CMM 800T Magnesium Alloy Die Casting Electroplating Power Tool Parts

Comparison of mechanical Properties of several die-casting alloys (ratio to density in parenthesis)

| Description: |

magnesium alloy (AZ91D) |

aluminium alloy (A380) |

zinc alloy (AG40A) |

|

| Density (g/cm3) | 1.8 | 2.7 | 6.7 | |

| Tensile strength (Mpa) |

230 (130) |

330 (120) |

280 (42) |

|

| Yield strength (Mpa) | 160(88) | 170(61) | - | |

| Shear strength (Mpa) | 140(77) | 190(69) | 210(32) | |

|

3 | 3 | 10 | |

| Tensile modulus of Elasticity (Gpa) | 45(25) | 71(26) | - | |

| Shear stiffness modulus (Gpa) | 17(9) | 27(10) | - | |

| Brinell | 63 | 80 | 82 | |

|

fatigue strength Moore 5*100000000(Mpa) |

97(54) | 150(54) | 48(7.1) | |

|

Creep strength (Mpa) |

70.F,100 hour | 140(77) | 170(61) | 76(11) |

| 200.F,100 hour | 80(50) | 160(59) | 24(3.6) | |

| 70.F,100 day | 140(77) | 170(61) | 48(7.2) | |

|

5000psi | 25 | 1 | 18 |

| 15000psi | 53 | 4 | 40 |

|

Advantage:

FAQ:

1. Q:Are you a factory or a trading company?

A:We are a factory which has been focus on Magnesium alloy deep processing lightweight field & semi-solid injection molding of Magnesium alloy for more than 16+ years.

2. Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control.

3. Q: Has the company established and implemented a standard procedure for purchasing contract review and approval?

A: Yes, with written standard procedures.

4. Q: Is there a procedure to conduct random product inspections after final packaging?

A: Yes, with clear standard and written inspection records.

5. Q: How can I get a quotation?

A: Please kindly send us following information 1) Product drawings by STEP/STP/PRT/PDF/IGS format etc. 2) Material, size and surface treatment request. 3) Required quantity. Normally,the quote will be offer in 1-6 hours. :)

6. Q: What is your payment terms?

A: T/T, Western Union, etc.