| Price | Negotiable |

| MOQ | Negotiable |

| Delivery Time | 7-15 work days |

| Brand | EMT |

| Place of Origin | CHINA |

| Certification | TS16949、IOS9001 |

| Packaging Details | According to customer needs |

| Payment Terms | T/T, Western Union |

| Supply Ability | 50000PCS /Month |

| Model of production equipment | 800T Magnesium alloy semi-solid injection molding machine | Place of Origin | CHINA |

| Packaging Details | According to customer needs | Material | Magnesium alloy |

| Supply Ability | 50000PCS /Month | Tolerance | Surface Roughness | +/-0.005-0.01mm | Ra0.2 - Ra3.2 (Customize avaiable ) |

| Certification | TS16949、IOS9001 | Processing | CNC Turning, Milling parts, Dilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. |

| Brand Name | EMT | Payment Terms | T/T, Western Union |

| Price | Negotiable | Delivery Time | 7-15 work days |

| Minimum Order Quantity | Negotiable | Application | Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medicaldevice, Telecommunications |

| Reduce noise | Good |

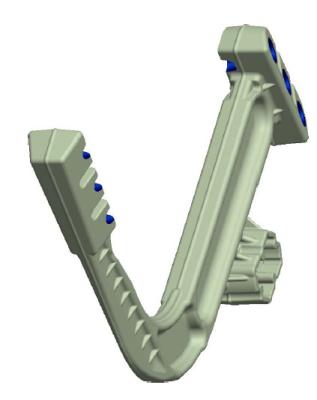

3C Products Shell Magnesium Zinc Alloy Aluminum Iron Power Tool Parts

Necessary wall thickness to weight ratio of engineering plastics and magnesium alloys:

|

proportion | Necessary wall thickness (mm) |

|

| magnesium alloy | 1.80 | 0.59 | 59 |

| PC/ABS | 1.14 | 1.60 | 100 |

| PC/GF(15%) | 1.34 | 1.26 | 93 |

|

Carbon fiber reinforced thermoplastic resin CFRTP(CF13%)

|

1.32 | 1.11 | 81 |

|

Carbon fiber reinforced thermoplastic resin CFRTP(CF13%)

|

1.50 | 0.89 | 73 |

Advantage:

The proportion of magnesium alloy is 2/3 that of aluminum alloy and 1/4 that of zinc alloy. Compared with plastic materials, the proportion of magnesium alloy is 1.5 times that of ordinary plastic. The gravity of magnesium alloy is the lightest among all structural alloys, so it is very suitable for the shell of 3C products.

Advantage:

FAQ:

1. Q:Are you a factory or a trading company?

A:We are a factory which has been focus on Magnesium alloy deep processing lightweight field & semi-solid injection molding of Magnesium alloy for more than 16+ years.

2. Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control.

3. Q: Has the company established and implemented a standard procedure for purchasing contract review and approval?

A: Yes, with written standard procedures.

4. Q: Is there a procedure to conduct random product inspections after final packaging?

A: Yes, with clear standard and written inspection records.

5. Q: How can I get a quotation?

A: Please kindly send us following information 1) Product drawings by STEP/STP/PRT/PDF/IGS format etc. 2) Material, size and surface treatment request. 3) Required quantity. Normally,the quote will be offer in 1-6 hours. :)

6. Q: What is your payment terms?

A: T/T, Western Union, etc.