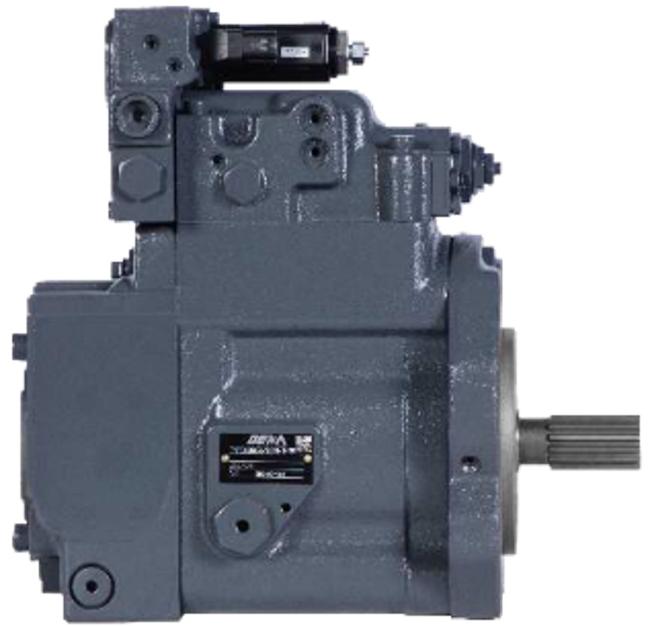

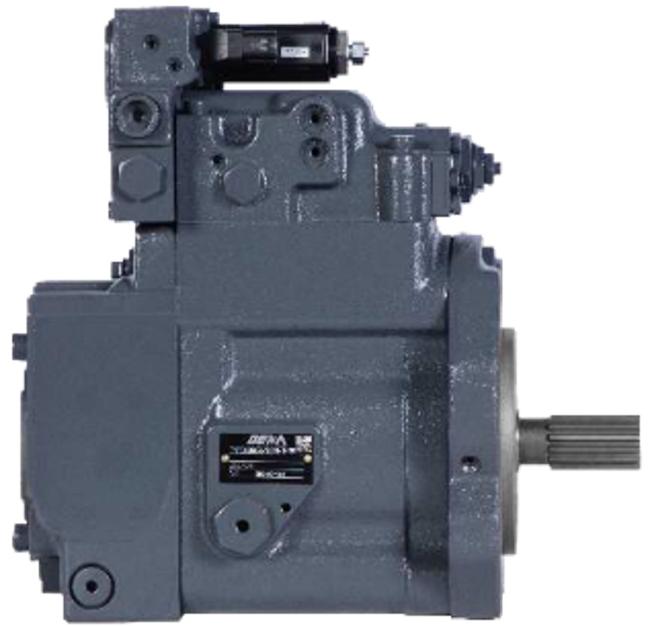

Product

Introduction

Manufactured

in

strict

adherence

to

ISO

4413

and

SAE

J1995

global

industry

standards,

the

K3V63-102R-1F29

Fan

Pump

delivers

stable

pressure

transmission

and

uniform

fluid

circulation—two

indispensable

elements

for

sustaining

smooth,

high-efficiency

operation

of

ZX470-3/1450-3

excavators,

even

during

heavy-load

tasks

(such

as

rock

breaking

or

bulk

material

handling)

or

long-duration

work

shifts.

Its

seamless

compatibility

with

ZX470-3/1450-3

models

is

validated

through

a

suite

of

rigorous

verification

tests,

covering

dynamic

load

simulations,

dimensional

precision

checks,

and

on-machine

fitment

trials.

These

tests

ensure

a

streamlined

installation

process,

removing

the

need

for

complicated,

time-intensive

modifications.

In

turn,

maintenance

teams

can

complete

replacement

work

more

quickly,

while

the

risk

of

unplanned

downtime—often

triggered

by

ill-matched

or

incompatible

parts—is

significantly

reduced.

Long-lasting

performance

is

a

standout

trait

of

the

K3V63-102R-1F29.

Its

key

internal

components

(including

rotors

and

seals)

are

crafted

from

premium

wear-resistant

stainless

steel

alloys,

and

the

outer

shell

is

reinforced

with

high-strength

cast

iron—design

features

that

enable

it

to

withstand

the

harsh

operating

environments

common

in

large-scale

construction,

deep-pit

mining,

and

large-area

landscaping

projects.

These

environments

typically

involve

prolonged

dust

immersion,

intense

mechanical

vibration,

and

extreme

temperature

swings

(from

-10°C

to

60°C).

For

excavator

operators

and

fleet

supervisors,

selecting

this

fan

pump

means

enhancing

the

operational

reliability

of

their

ZX470-3/1450-3

machines,

prolonging

the

overall

service

life

of

the

equipment,

and

cutting

down

on

long-term

costs

associated

with

frequent

repairs

and

part

swaps.

Whether

it’s

used

to

replace

a

worn-out

original

fan

pump

or

kept

in

inventory

as

a

backup

for

proactive

fleet

maintenance

planning,

the

K3V63-102R-1F29

meets

the

high

standards

of

dependability

and

performance

that

owners

of

ZX470-3/1450-3

excavators

demand.

It

has

emerged

as

a

trusted

solution

for

ensuring

these

heavy-duty

excavators

remain

productive

and

efficient,

regardless

of

the

specific

job

site

conditions

or

operational

requirements.

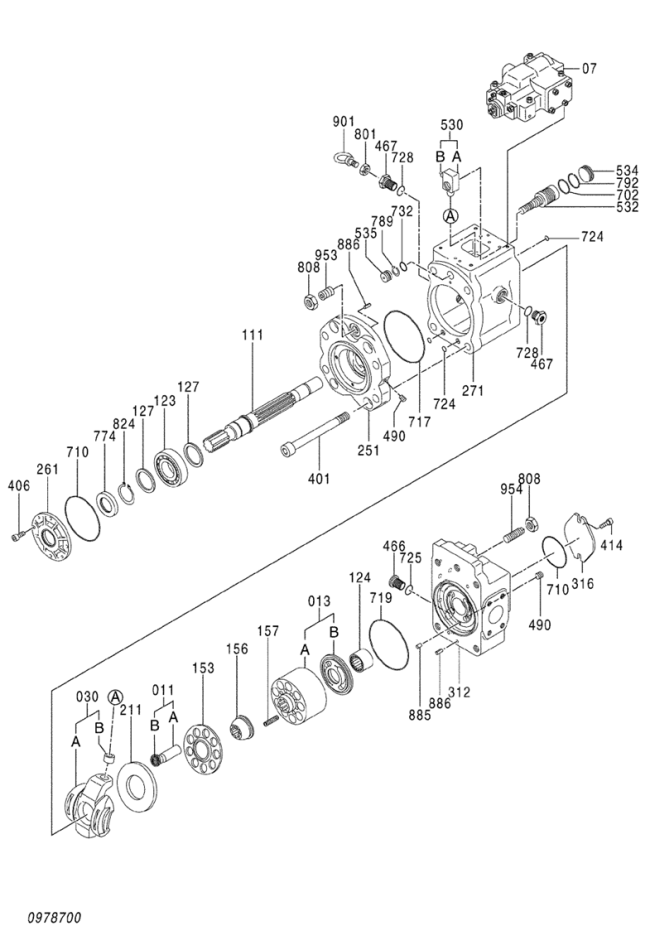

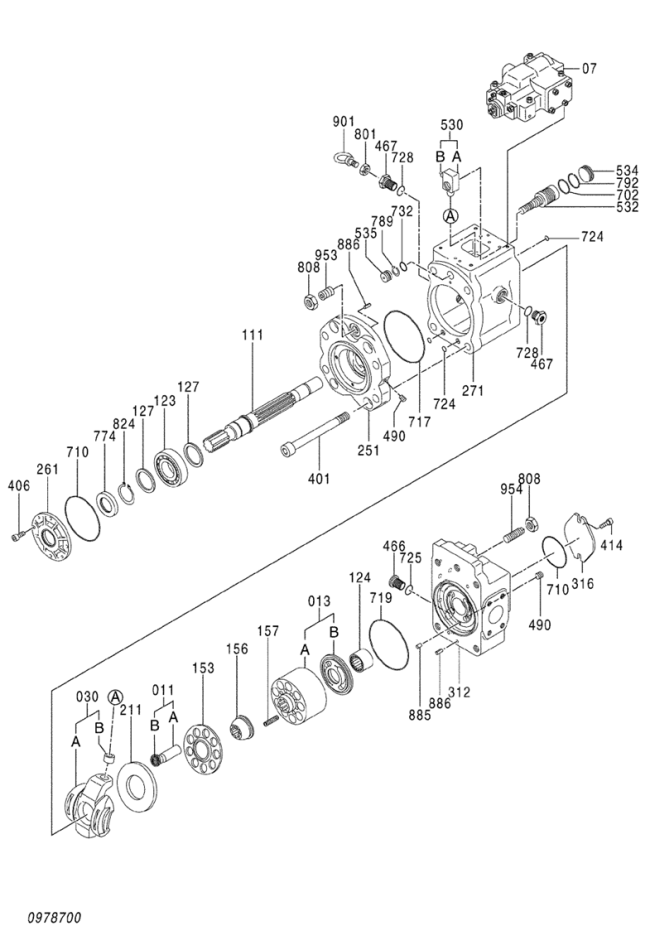

Parts

Show

|

4633472

|

[1]

|

PUMP;PISTON

|

|

7

|

4633474

|

[1]

|

PUMP;REGULATOR

|

|

11

|

4658832

|

[1]

|

PISTON

|

|

011A.

|

928006

|

[9]

|

PISTON

|

|

011B.

|

十十十十十十十

|

[9]

|

SHOE

|

|

13

|

十十十十十十十

|

[1]

|

CYL.

|

|

013A.

|

978701

|

[1]

|

BLOCK;CYL.

|

|

013B.

|

十十十十十十十

|

[1]

|

PLATE;VALVE

|

|

30

|

十十十十十十十

|

[1]

|

PLATE

|

|

030A.

|

818503

|

[1]

|

PLATE

|

|

030B.

|

十十十十十十十

|

[1]

|

BUSHING

|

|

111

|

十十十十十十十

|

[1]

|

SHAFT

|

|

123

|

818504

|

[1]

|

BRG.;ROL.

|

|

124

|

878107

|

[1]

|

BRG;NEEDL

|

|

127

|

924003

|

[2]

|

SPACER

|

|

153

|

818508

|

[1]

|

PLATE

|

|

156

|

818509

|

[1]

|

BUSHING;SPH.

|

|

157

|

818510

|

[9]

|

SPRING

|

|

211

|

818511

|

[1]

|

PLATE

|

|

251

|

818512

|

[1]

|

SUPPORT

|

|

261

|

818513

|

[1]

|

COVER

|

|

271

|

978702

|

[1]

|

CASING;PUMP

|

|

312

|

928002

|

[1]

|

COVER

|

|

316

|

820422

|

[1]

|

COVER

|

|

401

|

818519

|

[4]

|

BOLT;SOCKET

|

|

406

|

237902

|

[4]

|

BOLT;SOCKET

|

|

414

|

820425

|

[2]

|

BOLT;SOCKET

|

|

466

|

629404

|

[1]

|

PLUG

|

|

467

|

818520

|

[2]

|

PLUG

|

|

490

|

263019

|

[8]

|

PLUG

|

|

530

|

818521

|

[1]

|

PIN

|

|

530A.

|

十十十十十十十

|

[1]

|

PIN

|

|

530B.

|

十十十十十十十

|

[1]

|

PIN

|

|

532

|

878116

|

[1]

|

PISTON

|

|

534

|

924006

|

[1]

|

STOPPER

|

|

535

|

818524

|

[1]

|

STOPPER

|

|

702

|

443404

|

[1]

|

O-RING

|

|

710

|

A811085

|

[2]

|

O-RING

|

|

717

|

A811120

|

[1]

|

O-RING

|

|

719

|

A811115

|

[1]

|

O-RING

|

|

724

|

4506408

|

[9]

|

O-RING

|

|

725

|

95736

|

[1]

|

O-RING

|

|

728

|

4506418

|

[2]

|

O-RING

|

|

732

|

443407

|

[1]

|

O-RING

|

|

774

|

924007

|

[1]

|

SEAL;OIL

|

|

789

|

4085607

|

[1]

|

RING;BACK-UP

|

|

792

|

249148

|

[1]

|

RING;BACK-UP

|

|

801

|

124811

|

[1]

|

NUT

|

|

808

|

131108

|

[2]

|

NUT;LOCK

|

|

824

|

991342

|

[1]

|

RING;RETAINING

|

|

885

|

175241

|

[1]

|

PIN

|

|

886

|

244604

|

[2]

|

PIN;SPRING

|

|

901

|

4163072

|

[1]

|

BOLT;EYE

|

|

953

|

978703

|

[1]

|

SCREW;SET

|

|

954

|

978704

|

[1]

|

SCREW;SET

|

|

4658832

|

[1]

|

REGULATOR;PUMP

|

|

79

|

4654325

|

[1]

|

VALVE;REDUCING

|

|

412

|

135904

|

[2]

|

BOLT;SOCKET

|

|

413

|

213208

|

[2]

|

BOLT;SOCKET

|

|

418

|

667626

|

[2]

|

BOLT;SOCKET

|

|

436

|

211510

|

[4]

|

BOLT;SOCKET

|

|

438

|

102411

|

[8]

|

BOLT;SOCKET

|

Why

Choose

TGFQ

Over

Other

Excavator

Part

Dealers?

TGFQ

stands

out

with

3

unique

advantages:

Model-specific

expertise:

We

don’t

just

sell

parts—our

team

can

cross-reference

part

numbers

with

your

excavator’s

VIN

to

ensure

100%

fit

(we’ve

helped

500+

clients

avoid

“wrong

part”

delays

in

the

past

year).

Flexible

solutions

for

every

client:

Whether

you’re

a

small

repair

shop

needing

1

sample

part

(we

accept

orders

as

low

as

$50)

or

a

large

fleet

needing

100+

engine

Assemblys

(we

offer

bulk

discounts

up

to

15%),

we

adapt

to

your

needs.

Post-purchase

support:

Beyond

delivery,

we

provide

free

maintenance

guides

(e.g.,

“How

to

Extend

Hydraulic

Pump

Life”)

and

quarterly

check-ins

to

update

you

on

part

upgrades

for

your

machine

model.

With

clients

in

30+

countries

(including

repeat

customers

like

a

Southeast

Asian

construction

firm

that’s

partnered

with

us

for

10

years),

TGFQ

delivers

more

than

parts—we

deliver

reliability

you

can

count

on.