| Price | Negotiable |

| MOQ | 1 Piece |

| Delivery Time | General Order 15-30 Days |

| Brand | LBS |

| Place of Origin | Shijiazhuang Hebei China |

| Certification | CCS |

| Model Number | LBSS Series |

| Packaging Details | Export Standard Wooden Case |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1000 Pieces Per Month |

| Place of Origin | Shijiazhuang Hebei China | Packaging Details | Export Standard Wooden Case |

| Color | gray | Material | steel Q335B |

| Model Number | LBSS Series | Supply Ability | 1000 Pieces Per Month |

| Product Status | New | Certification | CCS |

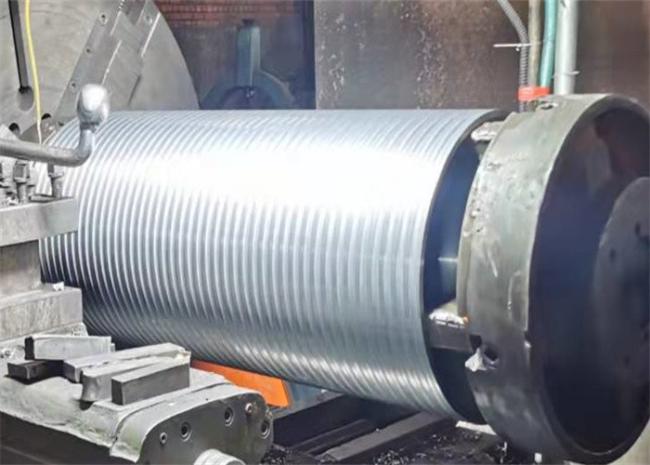

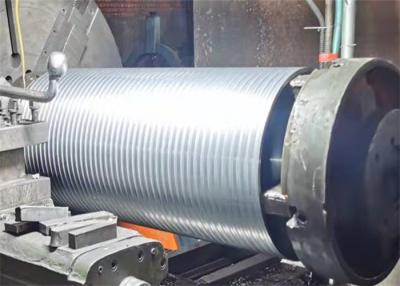

| Grooved type | lebus groove | Brand Name | LBS |

| Payment Terms | L/C, T/T, Western Union | Connection Type with drum | Bolted |

| Groove Type | Lebus Grooves | Dia.of rope | 3~60mm |

| Price | Negotiable | Delivery Time | General Order 15-30 Days |

| Product name | Grooved Cable Drum | Minimum Order Quantity | 1 Piece |

| layers | 2~20 Layers | Grooving Machining | CNC Machining |

Compared with the general non grooved (smooth) drum and spiral grooved drum, the Grooved Steel Drum Sleeves has obvious advantages in the neat winding of multi-layer steel wire rope. Lbs double fold rope groove makes the winding of steel wire rope more smooth and the load between layers is evenly distributed, reduces the irregular, disorderly winding and rope biting in the process of steel wire rope arrangement, reduces the damage of steel wire rope, prolongs the service life of steel wire rope, improves the safety of equipment operation, and avoids the shutdown time of mechanical equipment due to disorderly rope replacement.

In the winch, the wire rope plays an irreplaceable effect, so how can we do to avoid the phenomenon of wire rope there is disorderly rope? As a winch, it also makes some methods to avoid wire rope chaos, its drum has more obvious groove, double drum winch, these grooves can be better fixed wire rope.

how should we do? First, the wire rope is not sorted out before hoisting, and the wire rope is checked by itself, and the wire rope with a higher proportion of broken rope should be replaced in time. Second, do a good job of fixing the winch, the base of the winch is unstable, and the winch is prone to displacement when lifting. Show ropes. Third, when lifting, adhere to the wire rope and drum into a 90 degree Angle. The above is to avoid the method of small winch wire rope chaos. There are many parts on the winch. The effect of different parts is different, and the fault response method will be different

1) Wire rope or cable diameter (mm)

2) The inner diameter of the sleeves? (or the outer diameter of the smooth drum)

3)

The

length

of

the

sleeves?

(or

the

distance

between

two

flanges

,no

wear

plates)

4)

Material of

the

drum

sleeves

5)

The

rotation

direction

of

the

drum

groove?

6)

Type

of

rope

entry

| No: | Wire diameter(mm): | Rotation direction |

Main

drum diameter(mm) |

Main drum length(mm) | Application |

| 1 | 8 10 13 | Lefthand,Righthand | 430 | 763 |

The

oil

workover

rig

winch, Towing winch Tower crane |

| 2 | 13 18 20 | Lefthand,Righthand | 623 | 1144 |

Engineering

winch, Lifting winch,Crawler crane |

| 3 | 22 25 26 | Lefthand,Righthand | 730 | 1220 |

Oil

workover

rig

, Logging Winch |

| 4 | 18 22 32 | Lefthand,Righthand | 670 | 1240 |

Drilling

Rig

Winch, drawworks |

| 5 | 28 32 36 40 | Lefthand,Righthand | 560 | 630 |

Rotating

Drilling

Rig

winch, Lifting equipment |

| 6 | 26 28 32 45 | Lefthand,Righthand | 760 1146 | 1970 1765 |

Offshore

Crane, |

1.

Marine

ship

machinery:

offshore

oil

crane

winch,

mooring

winch,

traction

winch,

towing

winch,

anchor

winch

and

hydrological

winch

2.

Petroleum

industry:

oil

drilling

rig,

oil

logging

truck

winch,

oil

workover

rig,

wiper,

oil

truck

winch,

etc

3.

Hoisting

machinery:

crane,

tower

crane

winch,

gantry

crane

winch,

crawler

crane

winch,

tire

crane

winch

4.

Construction

machinery:

construction

wall

cleaning

winch,

single

drum

winch

and

double

drum

winch

5.

Other

construction

machinery:

cable

winch,

tower

crane,

pile

driver,

electric

hydraulic

winch

6.

Mining

machinery:

dispatching

winch,

traction

winch,

inclined

shaft

winch,

etc

LBS groove in each circle inside the drum are composed of straight line groove and diagonal rope groove, and each circle straight wire rope groove and diagonal rope groove position is exactly the same. when the wire rope for multi-layer winding, through the diagonal rope groove fixed upper wire rope and the lower rope crossover point position, the crossover of the upper steel wire rope in the oblique line. in the straight rope groove,the upper steel wire rope completely falls into the grooves formed by two lower steel wire ropes, form line contact between ropes, the contact between the upper and the lower rope is stable,when the return line, step retaining ring with return flange on both ends of the drum,guide wire rope to climb smoothly and return, avoid the rope disorder caused by mutual extrusion. so The wire rope is orderly and smoothly transferred to the upper layer ,Realize multi-layer winding.

When the split type drum fence skin is installed, the split fence skin sleeve is wrapped on the smooth slotless drum, and is closely connected with the drum through bolts or welding, so that the original smooth surface of the drum outside the surface becomes the form of lebus double folding rope groove, which is convenient for the application of winch modification or replacement of the drum.