| Price | USD, EUR, RMB / Negotiable |

| MOQ | 1 Piece |

| Delivery Time | General order 15-30 days |

| Brand | LBS |

| Place of Origin | Shijiazhuang Hebei China |

| Certification | ccs |

| Model Number | According to drawings or sample |

| Packaging Details | Export standard wooden case |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1000 Pieces Per Month |

| Place of Origin | Shijiazhuang Hebei China | Warranty | 13 Months |

| rocessing Type | Quenching | Packaging Details | Export standard wooden case |

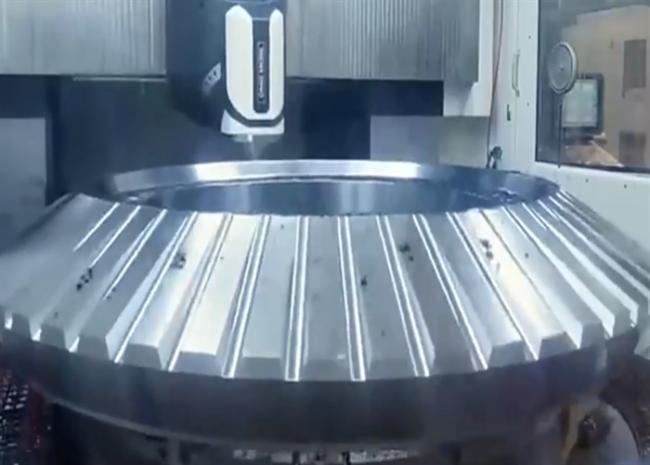

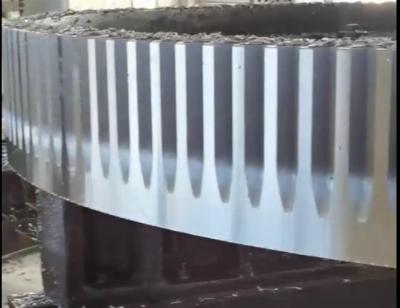

| Product Name | steel gear ring | Material | Metal Alloy Steel |

| Accuracy Class | 60Class | Model Number | According to drawings or sample |

| Supply Ability | 1000 Pieces Per Month | Certification | ccs |

| Forging Heat-treatment | Normalizing Treatment | Brand Name | LBS |

| Payment Terms | L/C, T/T, Western Union | Heat Treatment | Surface Carburizing |

| Price | USD, EUR, RMB / Negotiable | Delivery Time | General order 15-30 days |

| Supply abilitty | 2600sets /per month | Minimum Order Quantity | 1 Piece |

| Surface State | Grinding |

| Model | steel gear ring |

| Type | Round/Worm gear/bevel/Non-round /Rac Plastic stainless steel |

| Tooth shape | spur/bevel/curve/double gear |

| Production type |

Casting/cutting/rolling/sintered gear |

| Wrapped | wooden box |

|

Application

scope |

textile, agriculture, mining, food, oil and other transmission machinery |

| Hardness | hardening |

| MOQ |

≥100 pieces |

| Name | 15 m large diameter module 28 alloy steel stainless steel gear ring |

| Machining module | 0.2-10 |

| Materials: | stee45#l, 40CR, Easy car iron (1214#), brass, tin bronze, POM(Sisteel), PVD, PVDFl, imported nylon, stainless steel 303#, stainless steel 304#, aluminum 606#, aluminum 6063# |

|

Surface treatment: blackening, |

high frequency, carburizing and quenching, surface nitriding, etc |

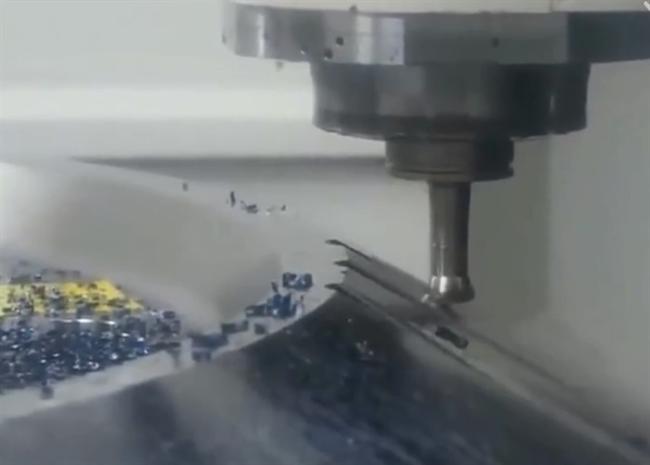

| Processing equipment: | CNC lathes, automatic lathes, general lathes, hobbing machine, gear shaper, gear milling machine, shaving machine, milling machine, grinding machine, wire cutting, etc |

| Processing technology | hobbing, gear, shaving, milling teeth |

| Common spur gear specifications | |||||||

| Modulus | 1M | 1.5M | 2M | 2.5M | 3M | 4M | 5M |

| tooth thickness | 10mm | 15-18mm | 20mm | 25mm | 30mm | 35-40mm | 40-50mm |

| inner hole | The blank hole | ||||||

| setting method | Outer diameter = module * (Number of teeth -2) | ||||||

Involute

gear

processing

methods

have

two

categories,

one

is

the

copying

method,

with

a

forming

cutter

milling

gear

groove,

is

"imitation

shape".

The

other

is

the

generativity

method.

(1)

Hobbing

machine

hobbing:

can

process

8

module

below

the

helical

teeth

(2)

Milling

machine

teeth:

can

process

straight

rack

(3)

Slotting

machine

gear:

can

process

internal

teeth

(4)

Cold

beating

machine

teeth:

no

chip

processing

(5)

Gear

planer

gear:

can

process

16

module

gear

(6)

Precision

casting

teeth:

cheap

pinion

can

be

processed

in

large

quantities

(7)

Gear

grinding

machine:

can

process

the

gear

on

the

precision

master

machine

Gear castings are also known as cast steel gears. This is because most gears are made of cast steel. Here I share some information about the production of gear castings and related heat treatment. Gear castings usually range in weight from a few kilograms to several tons.

Gear castings are usually made of high carbon cast steel, but some are made of alloy steel containing chromium, nickel and molybdenum to achieve high tensile strength. Large gears generally have lower physical requirements than pinions.

About the casting process, usually the floor molding process is suitable and can meet the normal demand. For cast steel gears, such as driven gears, gears and idler wheels, a floor molding process using quartz sand is a good choice. Why? Because most parts of the gear need machining. So, you don't need to use a higher casting process. In addition, for medium and large steel castings, the floor molding process using quartz sand is almost the only option.

Regarding heat treatment, of course, all steel castings must be standardized to eliminate internal pressures. Some parts of the gear casting can be welded. If the foundry welds castings, the weld position must be annealed. If the hobbing is extremely hard, you can anneal again to reduce the hardness and eliminate internal hard spots. After machining and hobbing, a gear is hardened or hardened to improve the surface hardness of its teeth. For pinion gear, you can do carburizing. For large driven gears, you can do surface hardening. Gears that have not been hardened have a short life span of only a few weeks to a few months.

Because gear castings have higher requirements on materials, defects, processing and heat treatment. Moreover, orders for gear castings are relatively small. As a result, many steel foundries are reluctant to manufacture.

Some gears are made by forging process. Forging gear internal tissue density is better, higher strength. Forged gears can be used for more stringent working conditions. Cast gears have low strength but are widely used in general operating conditions. The cost of forging gears is high while the cost of casting gears is relatively low. The buyer shall select the appropriate manufacturing process according to the cost and conditions of use.