| Price | Negotiation |

| MOQ | Negotiation |

| Delivery Time | 15-45 days |

| Brand | Antaeus |

| Place of Origin | Hunan,China |

| Certification | / |

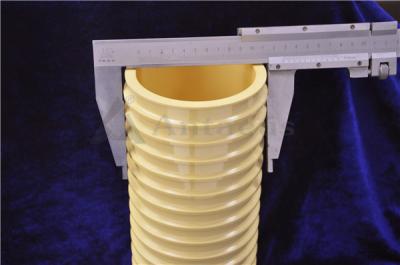

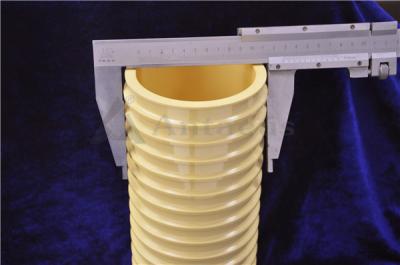

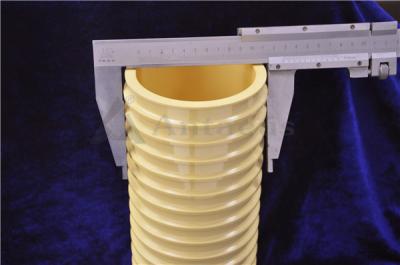

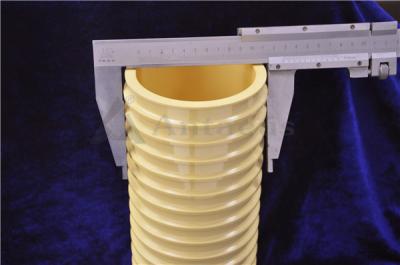

| Model Number | AD-Z018 |

| Packaging Details | Inner vacuum packaging, outside carton. |

| Payment Terms | T/T or Negotiation |

| Supply Ability | Full Supply |

| Place of Origin | Hunan,China | Tensile | 30 Kpsi - 32 Kpsi |

| Packaging Details | Inner vacuum packaging, outside carton. | Product Name | Zirconia Ceramic Parts / Structural Machining Ceramic Parts |

| Dielectric Strength | 16 KV/mm - 20 KV/mm | Model Number | AD-Z018 |

| Heat Expansion Rate (10-6K-1): | 10 | Supply Ability | Full Supply |

| Density | 6.0g/cm3 And 3.9g/cm3 | Certification | / |

| C.O.T.E | 75 In / In°C (x10^7) - 78 In / In°C (x10^7) | Brand Name | Antaeus |

| Payment Terms | T/T or Negotiation | Volume Resistivity | >10^14 Ohm-cm |

| Compressive | 300 Kpsi - 330 Kpsi | Price | Negotiation |

| Delivery Time | 15-45 days | Minimum Order Quantity | Negotiation |

| Working Temperature | 1500 °C - 1750 °C | Forming Process | Isostatic Pressing |

| Dielectric Constant | 9.5 - 9.8 | Fine-machining | CNC |

| Flexural | 55 Kpsi - 60 Kpsi |

Structural Machining Zirconia Ceramic Material Components IATF16949

1. Description:

Ceramic

knives

are

substantially

harder

than

steel

knives,

will

not

corrode

in

harsh

environments,

are

non-magnetic,

and

do

not

conduct

electricity

at

room

temperature.

Because

of

their

resistance

to

strong

acid

and

caustic

substances,

and

their

ability

to

retain

a

cutting

edge

longer

than

forged

metal

knives,

ceramic

knives

are

better

suited

for

slicing

boneless

meat,

vegetables,

fruit

and

bread.

Since

ceramics

are

brittle,

blades

may

break

if

dropped

on

a

hard

surface

although

improved

manufacturing

processes

have

reduced

this

risk.

They

are

also

unsuitable

for

chopping

through

bones,

or

frozen

foods,

or

in

other

applications

which

require

prying,

which

may

result

in

chipping.

1) High density.

2) High fracture toughness .

3) High hardness High Mechanical Strength.

4) Low thermal conductivity Excellent insulation .

5) Good Wear resistance.

6) Resistant to Corrosion and Chemical Attack.

7) Extreme Temperature Stability.

8) Outstanding Electrical and Electronic Properties.

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Assembing --- Brazing --- Inspecting --- Packing

6. Application Fields:

Widely apply for new energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

11.Shipping and Package:

12. Our aimed market :

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!