| Price | Negotiable |

| MOQ | 20KM |

| Delivery Time | 7 days |

| Brand | YUANTONG |

| Place of Origin | China |

| Certification | ROSH ,TLC, CCC, ISO |

| Model Number | GYTC8Y 48 Core |

| Packaging Details | Wooden Drum |

| Payment Terms | L/C, D/P, T/T, Western Union |

| Supply Ability | 500km per week |

| Place of Origin | China | Cable Sheath | HDPE |

| Packaging Details | Wooden Drum | Product Name | 48 Core Figure-8 PE sheath Full Filling Compound Communication Outdoor Fiber Optic Cable GYTC8Y |

| Model Number | GYTC8Y 48 Core | Fiber Count | 48 Core |

| Fiber Type | G652D | Cable Use | Outdoor |

| Supply Ability | 500km per week | Certification | ROSH ,TLC, CCC, ISO |

| Brand Name | YUANTONG | Payment Terms | L/C, D/P, T/T, Western Union |

| Cable Color | Blue Green Orange Brown | Price | Negotiable |

| Delivery Time | 7 days | OEM | Supported |

| Minimum Order Quantity | 20KM | Strength Member | Metallic strength member |

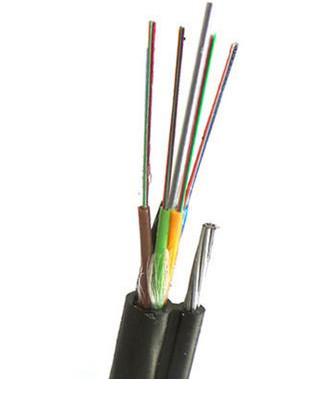

48 Core Figure-8 PE sheath Full Filling Compound Communication Outdoor Fiber Optic Cable GYTC8Y

Description:

A figure 8 fiber optic cable design incorporates a steel or dielectric messenger into the fiber optic cable thus, eliminating the need to lash a fiber optic cable to a messenger. A figure 8 fiber optic cable consists of three components: the messenger, the webbing, and the fiber optic cable. A figure 8 messenger cable has several advantages. Installation material cost may be reduced by eliminating the need to purchase a separate messenger wire and lashing wire. The labor cost can be greatly reduced in that there is only one installation job, installing the figure 8 cable. This compares with two installation jobs required when first the messenger must be installed, and then the cable installed by lashing it to the messenger. Typically, the overall cost of the installation may be reduced by as much as 40 %.

Characteristics:

High

tensile

strength

of

stranede

wires

meet

the

requirement

of

self-supporting

and

reduce

installation

cost

Good

mechanical

and

temperature

performance

High

strength

loose

tube

that

is

hydeolysis

resistant

Special

tube

filling

compound

ensure

a

critical

protection

of

fiber

The

following

measures

are

taken

to

ensure

the

cable

watertight:

Steel

wire

used

as

teh

central

strength

member

Loose

tube

filling

compound

100%

cable

core

filling

APL

moisture

barrier

| Model | Description | Applications | Tensile Strength (N) | Crush Resistance (N/100mm) | ||

| Long term | short term | Long term | short term | |||

| GYTC8Y | 48 Core Communication outdoor optical cable,Metallic strength member,Layer loose tube,full filling compound,PE sheath,Fig.8 self-supporting optical cable | Self-supporting overhead laying | 3000 | 7000 | 300 | 1000 |

|

Bned

Radius (mm) |

Working Temperature(℃) | Max. attenuation (dB/km) | fibers | OD(mm) | weight kg/km | |||

| Static(D) | Dynamic (D) | Min.TA | Max.TB | 1310μm | 1550μm | |||

| 10 D | 20 D | -40℃ | +60℃ | ≤0.36 | ≤0.22 | 2~144 | 8.2~17.8 | 102~268 |

| Category | Description | Specifications | |

| G.652D | |||

| Optical Specifications | Attenuation | @1310nm | ≤0.36dB/km |

| @1550nm | ≤0.22dB/km | ||

| Attenuation discontinuity | ≤0.05 dB | ||

| Attenuation vs. Wavelength | @1285~1330nm | ≤0.05 dB/km | |

| @1525~1575nm | ≤0.05 dB/km | ||

| Zero Dispersion Wavelength | 1300~1324nm | ||

| Zero Dispersion Slope | ≤0.092ps/(nm2.km) | ||

| Dispersion | @1310nm | ≤3.5 ps/nm.km | |

| @1550nm | ≤18 ps/nm.km | ||

| Polarization Mode Dispersion(PMD) | ≤0.2ps/km1/2 | ||

| Cable Cutoff Wavelength(λcc) | ≤1260nm | ||

| Effective Group Index of Refraction | @1310nm | 1.4675 | |

| @1550nm | 1.4681 | ||

| Macro bend loss (30mm radius,100turns) 1625nm | ≤0.1 dB | ||

|

Geometric Specifications |

Mode Field Diameter | @1310nm | 9.2±0.6μm |

| @1550nm | 10.4±0.8μm | ||

| Cladding Diameter | 125±1μm | ||

| Cladding Non-Circularity | ≤1.0% | ||

| Coating Diameter | 245±7μm | ||

| Coating/Cladding Concentricity Error | ≤8μm | ||

| Core/Cladding Concentricity Error | ≤0.8μm | ||

|

Mechanical Specifications |

Proof Test level | ≥1.0% | |

| Fiber Curl Radius | ≥4.0m | ||

| Peak Coating Strip Force | 1.3~8.9N | ||