| Price | Negotiable |

| MOQ | 10pcs |

| Delivery Time | 3-5days |

| Brand | Anping County Xinlu Wire Mesh Products Co.,Ltd |

| Place of Origin | Anping County, Hebei Province, China |

| Certification | CO |

| Model Number | XL - Water Well Screen - 029 |

| Packaging Details | wood case, pallet,container |

| Payment Terms | T/T |

| Supply Ability | 100pcs/20days |

| Another name | 4 Inch Dia Stainless Steel Well Screen Pipe 4 - 10mm Thickness For Water Well | Place of Origin | Anping County, Hebei Province, China |

| Filter type | screen pipe, screen tube, filter element, strainer pipe | advantage | easy cleaning, Easy Installation, long using life |

| Packaging Details | wood case, pallet,container | Material | low carbon steel, ss 304, ss316, ss316L, ss321,etc |

| Model Number | XL - Water Well Screen - 029 | Supply Ability | 100pcs/20days |

| Certification | CO | Surface treatment | Electrolytic polishing |

| Brand Name | Anping County Xinlu Wire Mesh Products Co.,Ltd | Payment Terms | T/T |

| End connection | welded rings, threaded, flange, blind end cap | Price | Negotiable |

| Delivery Time | 3-5days | Weave style | V wire or Wedge Wire Wrapped |

| Well Deep | 50-600m | Minimum Order Quantity | 10pcs |

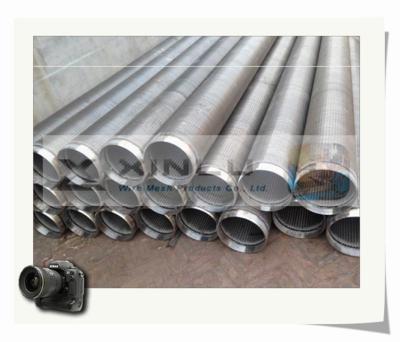

4 Inch Dia Stainless Steel Well Screen Pipe 4 - 10mm Thickness For Water Well

wedge wire screens, v shaped wire welded stainless steel water well screens, low carbon galvanized water well screen, Johnson screen tube, johnson screen pipe, johnson well screen, johnson wire screen, johnson filter screen, johnson v wire screens,v wire slot tube, wire wrapped screen pipe, oil well screens, dewatering well screen, perfect roundness screen tube, profile wire screen pipe, reverse rolled screen tube, spiral screen tube, screen cylinders, rod based continous slot screens, sand conrol well screen, wire wound screen pipe, stainless steel filter elements, wedge wire roll screen, stainless steel strainer pipe,

XinLu

factory's

water

well

screens

is

produced

by

a

perfect

combination

of

Vshaped

wire

and

V-shaped

rod

or

round

rod.

The

wire

is

welded

onto

the

rod

at each

intersection

point.

Water

well

screens

have

a

structure

and

high

open

area,

as

well

as

accurate

slot dimension.

At

the

same

time,

water

well

screen

have

heat-resisting,

anticorrosive,

good

machine

capability,

last

long,

safety

and

reliability

and

so

on characteristics.

It

can

be

used

in

many

kinds

of

medium

filtering.

Stainless Steel Water Well Screen Pipe

Slot Rod Based Continuous Slot Johnson Wire Wrapped Screen Tube

1. Inroduction:

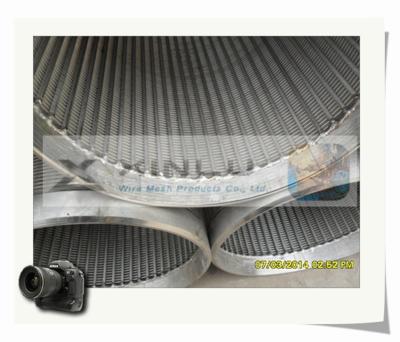

The welded stainless steel water well screen is made up of support wire and filter wire. with the material of stainless steel 302,304,316,304L,316L.

2. Component:

The support wires can be round wires, triangular wires or trapezoidal wires, while the filter wires is triangular wires(V shape wires).

3. Characteristics:

precise aperture size, high filter precision,firm structure, high-temperature resistance, corrosion resistance and mechanical performance is good,long service life, safe and reliable, etc. Can be used in various media filtration and screening.

4. Specifications for your reference:

| outside diameter | Sewing | Standard length | Specifications of filter wire | Specifications of support wire |

|

4'' ,6'' ,8'', 10'',12'' and etc. |

0.1-35mm | 50-6000mm |

2.2x3.0mm, 2.3x3.0mm, 3.0x4.6mm, 3.0x5.0mm |

3.8mm/22pieces, 3.8mm/32pieces. 3.8mm/48pieces, 3.8mm/50pieces |

5. Application:

widly used in coal,mine,water treatment and etc field.

Stainless Steel Water Well Screen Pipe Description:

Material:

Low

Carbon(Q195,

Q235)

Low

carbon

galvanized

Stainless

steel

(

304,

304L,316,

316L,

321)

Stainless

Steel

No

Magnetic(

201,

205)

Mild steel wire

Iron wire

Shape: Tube/pipe (Wire-wrapped stainless steel screen pipe, Water & Oil Well screen, Wedge wire screen, Changeable filter element, screen nozzle, Screen Cylinder, Spiral screen pipe, Strainer tube, Filter circumference, filter drum, v wire slot tube, screen basket. Cylinder screen,stainless steel lateral arm, hub lateral, head lateral,etc)

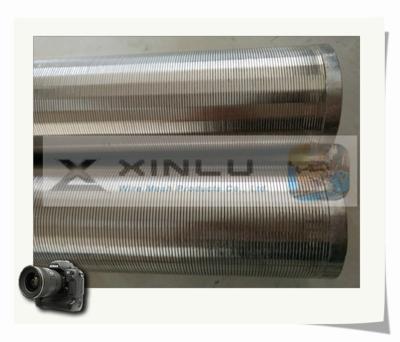

Slot (mm):0.08, 0.1, 0.15,0.20, 0.25, 0.30, 0.35, 0.40,0.45, 0.50, 0.60, 0.7, 0.75,1.00, 1.50, 2.00, 3.00 and so on.

Length ( mm): 50, 100, 200, 500, 1000,2000, 3000……6000( max)

Weaving: v wire / wedge wire wrapped Welded

LOOPED

WEDGE

WIRESCREEN

TUBE

Well

Scren

Tube

(Strainer

Pipe)

is

a

kind

of

filtered

water

tubing

with

the perforation.

it

can

use

with

the

deep

well

pump,

dive

the

water

pump,

also

may use

in

the

water-treating

equipment,

the

environmental

protection,

the

sea water

transforms

into

the

industrial

water

and

life

use

water

desalination treatment,

running

water

treatment,

water

softening

treatment,

the

petroleum industry:

The

petroleum

product

terminal

filters

and

the

chemical

acid,

the alkali

liquid

filters,

the

ethyl

alcohol

and

so

on

the

organic

solution

recycling filters.

WELDED

PROFILE

WIRE

SCREEN

PIPE/TUBE

End

connection:

welded

ring

threaded male

/female

coupling

V

WIRE

SLOT

TUBE

Used: Application in the water well, oil, mining, coal, oil, chemical fertilizers, food, environmental protection, sewage treatment, food filter screen mesh and other industries to sew, oil filter, wire net in salt industry,etc.

Stainless Steel Water Well Screen Pipe Specifications

| Material |

Size (Inch) |

OD (mm) |

Slot (mm) |

Length (m) |

Collapse Strength (PSI) |

Tensile Weight (TON) |

Profile wire (WXH) |

Support rod | End Connection |

|

Q195 Q235 201 205 321 304 304L 316 316L |

4 | 117 | 0.040 | 3-6 | 395 | 6 | 2.2*3.0 | 3.8MM/22 |

Threaded

Welded Rings

Flange |

| 4 | 114.3 | 0.040 | 3-6 | 395 | 6 | 2.3*3.0 | 3.8MM/22 | ||

| 6 | 168.3 | 0.040 | 3-6 | 252 | 8 | 2.3*3.5 | 3.8MM/32 | ||

| 8 | 219.1 | 0.010 | 3-6 | 399 | 10.5 | 3.0*4.6 | 3.8MM/48 | ||

| 8 | 219.1 | 0.020 | 3-6 | 370 | 10.5 | 3.0*4.6 | 3.8MM/48 | ||

| 8 | 219.1 | 0.040 | 3-6 | 323 | 10.5 | 3.0*4.6 | 3.8MM/48 | ||

| 10 | 273.1 | 0.010 | 3-6 | 206 | 11 | 3.0*4.6 | 3.8MM/50 | ||

| 10 | 273.1 | 0.020 | 3-6 | 191 | 11 | 3.0*4.6 | 3.8MM/50 | ||

| 10 | 273.1 | 0.040 | 3-6 | 167 | 11 | 3.0*4.6 | 3.8MM/50 |

Features: Consistent weld integrity at every point of welding.

Tight slot control for consistent flow rates.

Stringent Quality Control measures ensure a quality product.

Weld Rings or Threaded Fittings as per customer requirements.

Multiple wire profile options to suit applications and specification.

Geological formations comprised of small, fine particles

Water wells where gravel packs will be installed

Thin aquifers, where maximum open area is required

Large and small diameter deep wells

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.