| Price | USD 30~50/KG |

| MOQ | 30kg |

| Delivery Time | 10~15 Working days |

| Brand | CUBERYLLIUM® |

| Place of Origin | China |

| Certification | ISO ROHS |

| Model Number | Copper Alloy 173 |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Payment Terms | L/C, T/T |

| Supply Ability | 50T/Month |

| Place of Origin | China | Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Product Name | Copper Alloy 173 beryllium | CUBERYLLIUM® Grade | CUBERYLLIUM®-173 |

| Standard | ASTM B196 | Model Number | Copper Alloy 173 |

| Supply Ability | 50T/Month | Typical Application | Electrical Industry Application |

| Certification | ISO ROHS | Surface | Bright, Polish |

| Shape for available | Rod&Bar | Brand Name | CUBERYLLIUM® |

| Payment Terms | L/C, T/T | Brand | CUBERYLLIUM® |

| Price | USD 30~50/KG | Delivery Time | 10~15 Working days |

| Length | According customers' requirement | Minimum Order Quantity | 30kg |

| Temper | TD04 | Diameter | According customers' requirement |

Copper Alloy 173 beryllium Shape Rods/Bars By Standard ASTM B196

Product Description:

| Product Name | Copper Alloy 173 Beryllium Rods/Bars |

| Grade | Alloy 173 |

| End Product Form | Rods/ Bars |

| Standard | ASTM B196 |

| State of product | TD04 |

| Processing | Seamless / Welding |

| Feature | With high strength and high conductivity |

| Specification |

Dia. and Length: according customers' requirement |

CUBERYLLIUM® maintains an inventory of beryllium copper alloys, including beryllium copper strips, beryllium copper rods/bars, beryllium copper wires and so on.

The normal grades of beryllium copper alloy are C17200 and C17300, with high strength and moderate conductivity. C17200 & C17300 can be purchased in the solution annealed or cold worked tempers and can be easily formed or machined. A low-temperature heat treatment (600 degrees for 2-3 hours ) produces additional maximum strenght and hardness.

Chemical Composition of Copper Alloy 173 beryllium:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium |

Cobalt + Nickel |

+Cobalt + Nickel + Iron |

Pb | Copper |

| Cuberyllium-C173 | C17300 | 1.80-2.00 | 0.20 min | 0.6 max | 0.2~0.6 | Balance |

Note: Copper plus additions equal 99.5% minimum.

Typical Physical Properties of High Strength Beryllium Copper Alloys C17300:

Density: 8.36g/cm3

Density before age hardening: 8.25g/cm3

Melting Range: 870~980℃

Elastic Modulus((kg/mm2 (103)): 13.4

Thermal Expansion Coefficient(20 °C to 200 °C m/m/°C): 17 x 10 -6

Thermal Conductivity(cal/(cm-s-°C)): 0.25

Mechanical and Electrical Properties of Copper Alloy 173 beryllium Shape Rods/Bars:

| Temper(*) | Diameter | Heat Treatment | Tensile Strength ksi |

Elogation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B or C Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 400~600 | 30 | 15~19 | B45~85 |

|

H(TD04) |

5~10 | / | 660~900 | 5 | 15~19 |

>B88 |

| >10~25 | / | 620~860 | 5 | 15~19 | ||

| >25 | / | 590~830 | 5 | 15~19 | ||

| AT(TF00) | ALL SIZE | 3 hr 320°C | 1100~1380 | 2 | 22~28 | C35~42 |

| HT(TH04) | 5~10 | 2 hr 320°C | 1200~1550 | 1 | 22~28 | C37~45 |

| >10~25 | 1150~1520 | 1 | 22~28 | C36~44 | ||

| >25 | 1120~1480 | 1 | 22~28 | C35~44 |

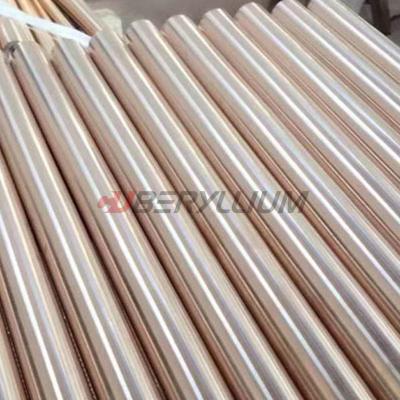

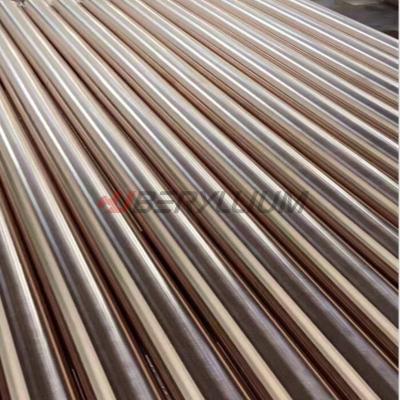

Product Photo:

Copper Alloy 173 Beryllium Applications:

1, Electrical Switch and Relay Blades;

2, Electric Motor Components;

3, Fasteners;

4, Non-sparding safety tools;

5, Industrial;

6, Pump Parts;

7, Electrical connectors.

As a leading beryllium copper alloys supplier, CUBERYLLIUM® attributes our success to serving our customers. through our service-minded employees and material readily available for prompt, accurate deliveries of copper beryllium alloys, including rods, bars, strips, wires, tubes, plates, and so on.