| Price | 32USD |

| MOQ | 10 |

| Delivery Time | 10~15days |

| Brand | CUBERYLLIUM® |

| Place of Origin | China |

| Certification | ISO,SGS |

| Model Number | CUBE2-UNS.C17200 |

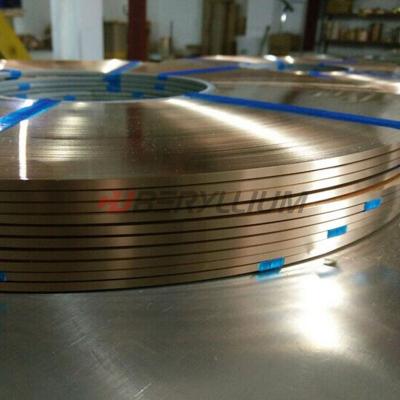

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 200T/Month |

| Place of Origin | China | Machining Property | Good |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

| Standard | ASTM Standard | Model Number | CUBE2-UNS.C17200 |

| Supply Ability | 200T/Month | Certification | ISO,SGS |

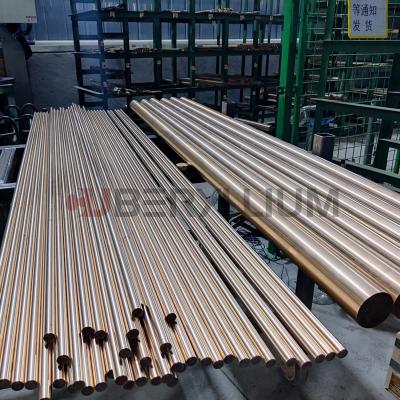

| Name | CUBE2-UNS.C17200 BERYLLIUM COPPER RODS | Surface | Bright/Polished |

| Brand Name | CUBERYLLIUM® | Payment Terms | L/C, T/T, Western Union |

| Dia. | 12MM 15MM 20MM 25MM 30MM | Safe Handling | No special health risk. |

| Price | 32USD | Delivery Time | 10~15days |

| State | TF00 | Minimum Order Quantity | 10 |

| Application | for industry | Flatness | Good |

CUBE2-UNS.C17200 BERYLLIUM COPPER RODS DIA.12MM 15MM 20MM 25MM 30MM

Introduction of CuBe2-UNS.C17200 Grade Mateial:

Be: 1.80-2.00; Ni + Co: 0.20 Min; Ni +Co +Fe: 0.60 Max; Al: 0.20 Max; Si: 0.20 Max; Cu: Balance

|

High hardness |

| High explosion resistance |

| Good corrosion resistance |

| High electrical conductivity |

| Excellent heat dissipation performance |

| High yield limit and fatigue limit |

The alloy has high chemical stability in the atmosphere, fresh water and sea water, has a small intergranular corrosion tendency and is resistant to impact corrosion. It also has good corrosion resistance in media such as dilute hydrochloric acid, acetic acid and phosphoric acid, but the corrosion speed is faster in wet ammonia, nitric acid and chromate solutions.

As Cube2 beryllium copper is easy to process and with its cooling effect, it is used in various fields:

| Electromic and electrical equipment |

| Aerospace |

| Automobile manufacturing |

| Hot runner cooling systems |

| Communication preparation equipment |

| Instrumentation |

| High electronics |

| Plastic and optical molds |

| Mold cores |

| Punches |

Material Standard of CuBe2:

| DIN | ASTM | RWMA |

| w.nr.2.1247 | C17200 | Class IV |

Technical parameters of CuBe2:

| Density | 8.36g/cm³ |

| Hardness | 36-46HRC |

| Tempere | TB00, TF00, TH04, TD04 |

| Thermal Expansion Coefficient | 17.5×10-6m/m℃ |

| Thermal Conductivity | 105W/m℃ |

| Melting Point(solidus) | 870℃ |

Product Photos:

CuBe2-UNS.C17200 Grade Mateial Aging

The aging of the parts should be carried out in a special fixture to prevent warping, deformation and ensure the dimensional accuracy of the parts. When bright treatment is required, a controlled atmosphere or vacuum furnace should be used. When the surface quality is not high or surface oxides are to be removed in subsequent processes, neutral salt furnaces or air circulation furnaces are allowed.

Surface treatment process

Soak in aqueous sodium hydroxide solution

Surface finish

To loosen the oxide film, then pre-corrode in aqueous hydrochloric acid solution, and finally perform bright treatment in a mixture of sulfuric acid and nitric acid.

Passivation treatment

Weakly corrode in dilute sulfuric acid solution first, then impregnate in a mixture of tyrosine (90g/L) and sulfuric acid (30g/L) at room temperature.

Machining and Grinding Performance The machinability of the alloy is 20% of that of the free-cutting brass HPb63-3.

FAQ:

1. How can I contact with your company?

We

are

always

ready

to

serve

you

via

Email,

Telephone,

Fax,

Whatsapp

or

Mobile

telephone.

Mobile/Wechat/Whatsapp:

+86-17376550856

Email:info@cuberyllium.com

2. What is the lead time?

Usually 7 days after payment has been confirmed.

3. What is your payment terms?

T/T,L/C,Western Union,MoneyGram,Paypal.

4. What’s your advantage?

1) Professional production equipment.

2)Smooth surface.

3) Complete specification