| Price | 30USD |

| MOQ | 10 |

| Delivery Time | 10~15days |

| Brand | CUBERYLLIUM® |

| Place of Origin | China |

| Certification | ISO,SGS |

| Model Number | CuBe2 W.Nr.2.1247 |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 200T/Month |

| Place of Origin | China | Machining Property | Good |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

| Standard | ASTM Standard | Model Number | CuBe2 W.Nr.2.1247 |

| Supply Ability | 200T/Month | Certification | ISO,SGS |

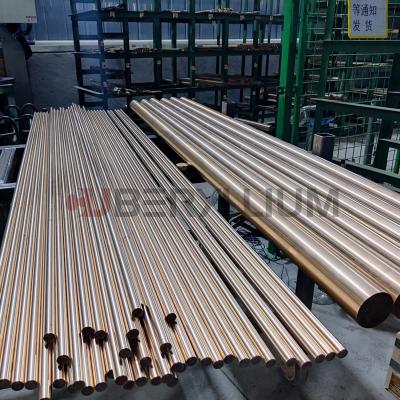

| Name | Copper Beryllium Rod CuBe2 W.Nr.2.1247 | Surface | Bright/Polished |

| Brand Name | CUBERYLLIUM® | Payment Terms | L/C, T/T, Western Union |

| Dia. | 10mm 16mm 20mm | Safe Handling | No special health risk. |

| Price | 30USD | Delivery Time | 10~15days |

| State | TD02, TD04, TF00 | Minimum Order Quantity | 10 |

| Application | for electrical industry | Flatness | Good |

Copper Beryllium Rod CuBe2 W.Nr.2.1247 With Diameter 10mm 16mm 20mm

Product Normal Description:

| Product Name | Copper Beryllium Rod |

| Material Alloy | CuBe2 |

| End Product Form | Round rods, bars |

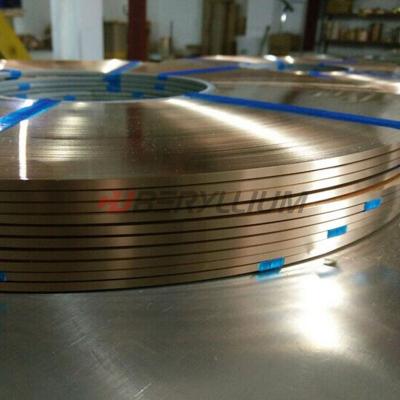

| Other Forms | Strips, flat bars, sheet, wire, tube |

| Product Brand | CUBERYLLIUM® |

| Product Size(Dia.) | 10mm 16mm 20mm |

| Product Size(Length) | 1m, 2m, 2.5m or customized length |

Chemical Coposition of Material CuBe2:

| Element | Composition % |

| Be | 1.80-2.00 |

| Ni + Co | Min. 0.20 |

| Ni +Co +Fe | Max. 0.6 |

| Al | Max. 0.20 |

| Si | Max. 0.20 |

| Cu | Remainder |

Introduction of Material CuBe2:

Cube2--W.Nr.2.1247, CW101C,has great hardness, very good strength, high electrical and thermal conductivity. It can be used in some applications which needs very high hardness. Additionally it is non-sparking material for using in combustible atmosphereBeryllium Copper is the most commonly utilized Copper Beryllium alloy and is notable for its highest strength and hardness compared to commercial copper alloys. C17200 alloy contains appr. 2% of beryllium and achieves its ultimate tensile strength can exceed 1360Mpa, while the hardness approaches Rockwell C45. Meanwhile, the electrical conductivity is a minimum of 22% IACS in the fully aged condition.C17200 also exhibits exceptional resistance to stress relaxation at elevated temperatures.

Material Standard of CuBe2:

| DIN | ASTM | RWMA |

| w.nr.2.1247 | C17200 | Class IV |

Application of Material CuBe2:

Alloy 25(C17200) is used to make oil drilling components such as MWD/LWD tools, drill collars and subs, flex subs and shafts, drill rods, drill bit bushings, valve components, pump shafts and fasteners. Alloy 25 strip is used to make essential parts in consumer electronics like pressure sensor bellows, burn-in and test socket contacts, computer processor socket contacts and electromagnetic shielding gaskets.

Product Photos:

By the physical shape, the proper analysis, and the correct mechanical values.

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications.

Different

copper

alloys

are

tested

for

a

very

long

time

and

always

applicable

to

individual

demands.

We

have

the

experience

to

help

customers

producing

customized

products

as

per

the

customers'

drawings.

Usually with 7-10 working days, it will depend on the final qty requested by customers.