| Price | USD 25/KG |

| MOQ | 30kg |

| Delivery Time | 10~15days |

| Brand | CUBERYLLIUM |

| Place of Origin | China |

| Certification | ISO ROHS |

| Model Number | C17510 |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 50T/Month |

| Place of Origin | China | Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Grade | C17510 | Standard | ASTM B441 |

| Specification | All Sizes | Model Number | C17510 |

| Supply Ability | 50T/Month | Density | 8.83g/cm3 |

| Certification | ISO ROHS | Name | Nickel Beryllium Copper UNS. C17510 Rods |

| Brand Name | CUBERYLLIUM | Payment Terms | L/C, T/T, Western Union |

| Brand | CUBERYLLIUM® | Price | USD 25/KG |

| Delivery Time | 10~15days | Length | 0.5~3m |

| Minimum Order Quantity | 30kg | Temper | TD02,TH04 |

| Application | Springs, Thermal Transfer Plates, Welding Equipments | Diameter | 8mm~30mm |

| Shape For Available | Rod, Bars, Round bars | Modulus of Elasticity Tension | 133Gpa |

Nickel Beryllium Copper UNS. C17510 Rods at Temper TH04 By ASTM B441

Product Description:

| Product Name | Nickel Beryllium Copper UNS. C17510 Rods |

| Grade | C17510 |

| End Product Form | Rods |

| Standard | ASTM B441 |

| State of product | TD02,TH04 |

| Processing | Bending, Welding |

| Feature | With high strength and high conductivity |

| Specification |

Dia 8~30mm; Length 0.5~3m or according customers' requirement |

Introduction of Nickel Beryllium Copper Alloy UNS. C17510:

These 17510 beryllium copper rods are not only conductive, but also non-sparking and non-magnetic, making them suitable for mines, oil rigs, and navigational tools. Containing beryllium and nickel, this alloy is stronger and more rigid than pure copper, though not as conductive. These rods are conductive enough for electrical relays, probe pins, and test-socket and modular-jack contacts, as well as strong enough for welding dies, plunger tips, and injection-mold nozzles. They maintain their shape despite collisions and frequent use, so they’re good for molds and cavities. Meeting RWMA Class 3, they’re recommended when seam and spot welding stainless steel and other electrically-resistant material. They also resist extreme temperatures and won’t rust outdoors.

Product Range of Cuberyllium:

Our product range includes a wide range of beryllium copper alloys, rwma beryllum copper alloys, such as beryllium copper strip, beryllium copper rod, beryllium copper plate, beryllium copper tube, beryllium copper wire, C17200 copper alloy, C17300 copper alloy, C17500 copper alloy, C17510 copper alloy, rwma class 3 copper alloy, rwma class 4 copper alloy. Our valued clients can avail from us an approved quality range of beryllium copper alloys.

Nickel

Beryllium

Copper

Rods

is

the

mirror

image

of

alloys

C17500

in

terms

of

its

properties

&

Characteristics.

CLASS

THREE

BERYLLIUM

COPPER

–

ALLOY

17510

ASTM

B441

ASTM

B534

MIL

C-81021

SAE

J461

SAE

J463

UNS

C17510

Class

3

Coppe

Chemical Composition of Nickel Beryllium Copper Alloy UNS. C17510:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Nickel | Cobalt+Nickel | Cobalt+Nickel+Iron | Lead | Copper |

| Cuberyllium-C751 | C17510 | 0.20 ~ 0.60% | 1.40 ~ 2.20% | - | - | - |

Balance |

Mechanical and Electrical Properties of Nickel Beryllium Copper Alloy UNS. C17510 Rods:

| Temper(*) | Diameter | Heat Treatment |

Tensile Strength Mpa |

Elongation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 240~380 | 20~40 | 20~35 | B20~50 |

| H(TD04) | ALL SIZE | / | 440~550 | 10~20 | 20~35 | B20~30 |

| AT(TF00) | ALL SIZE | 3 hr 480℃ | 680~900 | 10~30 | 45~60 | B92~100 |

| HT(TH04 | ALL SIZE | 2 hr 480 ℃ | 750~960 | 5~30 | 48~60 |

B95~102 |

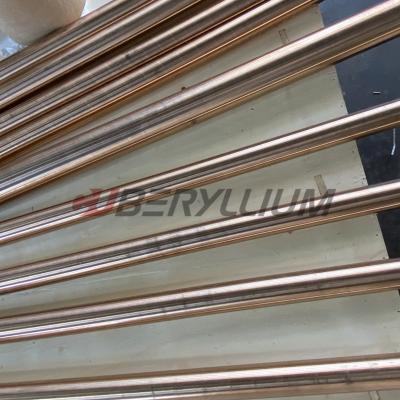

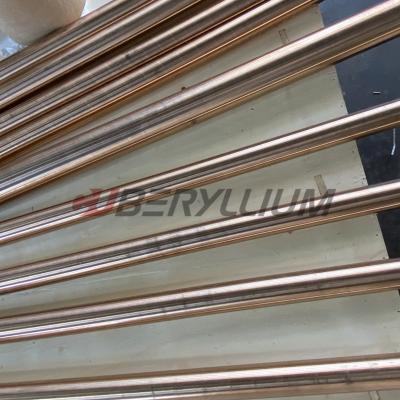

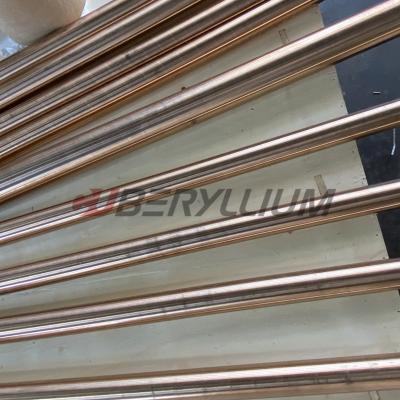

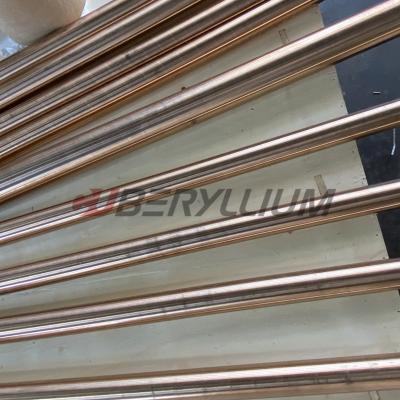

Product Photos:

FAQ:

By the physical shape, the proper analysis, and the correct mechanical values.

Different

copper

alloys

are

tested

for

a

very

long

time

and

always

applicable

to

individual

demands.

We

have

the

experience

to

help

customers

producing

customized

products

as

per

the

customers'

drawings.

Usually with 7-10 working days, it will depend on the final qty requested by customers.

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications.

Copper Alloys can be more susceptible to corrosion, particularly oxidation. which can impact it suitability for some applications.