| Price | $7800.00/Sets 1-4 Sets |

| MOQ | 1 set |

| Delivery Time | Negotiable |

| Brand | chuangying |

| Place of Origin | dongguan |

| Brand Name | chuangying | Place of Origin | dongguan |

| Price | $7800.00/Sets 1-4 Sets | Rated voltage | 220V±5% |

| Minimum Order Quantity | 1 set | Dimensions | 3800(L)×980(W)×1100(H)mm |

| Adaptable material | non-woven fabric (9-10g/m2) Rubber band model (30-40 yarn wrapping) | Rated power | 3Kw |

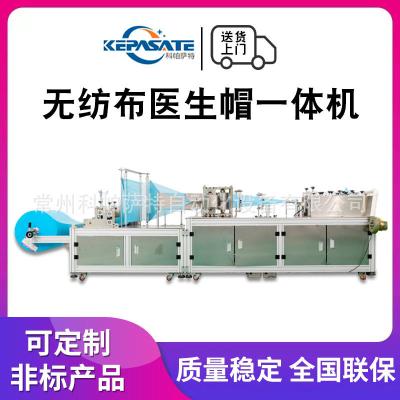

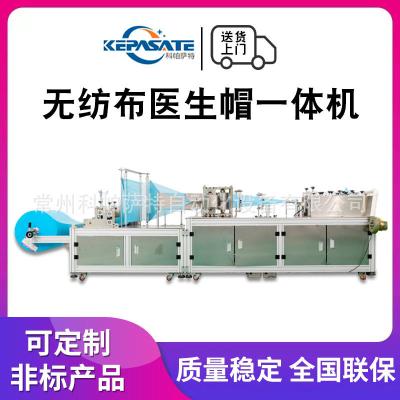

Hot Sale Machines For Making Hats Disposable Operating Hat Machine

Bar Cap Making Machine Instructions

The company independently developed "non-woven bar cap", which is the first manufacturer of elastic non-woven head cover.

Special machinery, the products are suitable for hospitals or dust-free industries, etc. The machine is stainless steel structure, independent

The electrical control box only needs one person to operate, from feeding to forming, counting and collecting to complete automatic control.

The system can produce up to 200 pieces per minute.

◆ High stability, excellent performance and low failure rate

◆ Stainless steel structure, independent electrical control box, compact machine, small rest volume

◆ The surface parts are all chrome-plated, and the cover parts are made of stainless steel, which is beautiful and clean

◆ Adjustable ultrasonic welding

◆ One machine is changeable, changing molds can produce bar caps of various specifications

◆ Electronic counting

◆ Automatic shutdown protection for broken material / broken ribs

|

Specifications of bar caps produced |

18′-24′ single rib/double rib |

| Production speed | According to the thickness of the material, the best control is 90-120p/m (the machine life can be lasting, more than 150 will damage the mold). |

|

Weight of the whole machine |

450KG |

|

Adaptable material |

non-woven fabric (9-10g/m2) Rubber band model (30-40 yarn wrapping) |

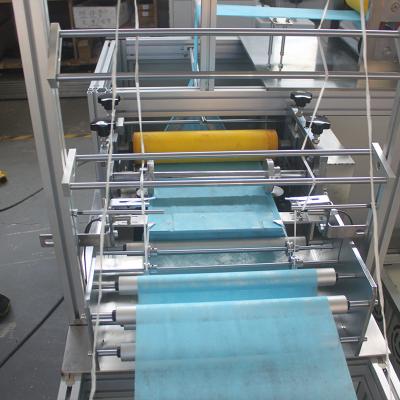

cloth

rubber

band

The

rubber

band

of

the

shower

cap,

except

the

fabric,

is

stretched

and

positioned

as

shown

in

the

picture

below

and

sent

to

the

machine.

The

blue

in

the

middle

is

the

fabric,

and

the

white

on

the

sides

are

the

elastics

that

act

as

elastics.

In

the

role

of

the

crimping

machine,

the

fabric

will

be

crimped

and

then

wrapped

around

the

elastic.

Continue

to

pass

through

the

front

heat

sealing

wheel,

and

weld

the

fabric

and

elastic

band

after

hemming

together.

The

welding

word

is

mentioned

because

the

elastic

band

and

the

non-woven

fabric

need

to

be

joined

together.

Welding

is

not

only

used

on

metals,

but

also

processing

fabrics

and

films

can

be

called

welding.