| Price | $1,500.00/ton 5-10 Sets |

| MOQ | 1 ton |

| Delivery Time | Negotiable |

| Brand | chuangying |

| Place of Origin | dongguan |

| Supply Ability | 1000ton |

| Brand Name | chuangying | Place of Origin | dongguan |

| Keywords | 100 PP Non Woven Fabric | Price | $1,500.00/ton 5-10 Sets |

| Product name | Non Woven Fabric | Minimum Order Quantity | 1 ton |

| Supply Ability | 1000ton | Application | Agriculture Cover |

| Name | 100% PolyPROPYLENE Spunbonded Nonwoven Fabric |

| Packing | Roll Packing |

| Technology | Meltblown Pp Nonwoven Fabric |

| Usage | Medicl |

| Type | Hot-stamping Non-woven Fabric |

| item | value |

| Supply Type | In-Stock Items |

| Pattern | SOLIDS |

| Feature | Waterproof, Breathable, Anti-Bacteria, Shrink-Resistant, Water Resistant, Wrinkle Resistant, Oilproof |

| Material | 100% Polypropylene |

| Weight | 25g/40g |

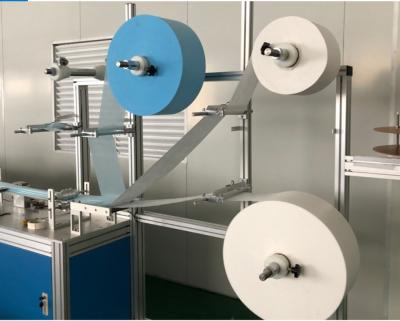

Hello, please don't feel strange when you see words like mine. I am the boss of this mask machine enterprise. I have been doing research and development of machinery and equipment for ten years. I didn't expect the sudden outbreak of the epidemic this year to transform our company into mask machines. I have always been very strict in doing things, and so has the mask machine designed by our company. I have participated in the control of our machines from design to purchase related raw materials. Every detail of the machine is done with great precision. The machine runs stably and is easy to operate. There is a Korean interface. At present, plane mask machines have been made for more than 1,000 years this year, and KF94 South Korea has exported more than 200 units. The factory still has 100 semi-finished products in stock. Can be assembled, installed, debugged and shipped at any time. The fastest delivery speed can be one to two days. Special custom-made mask appearance, 10 days delivery.

common

problem

Q:

Are

you

a

factory

or

a

trading

company?

A: We are a factory with import and export license.

Q: Where is your factory?

A: Our factory is located in Guangdong, China.

Q: How long is the warranty period?

Answer: The shelf life is one year.

Q: How about the installation? Do you have after-sales service?

Answer: South Korea and Vietnam have after-sales service and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install it in this way. Just install the four screws of the connector of the film sticking machine and the earband machine, learn to install the cloth and then operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: Why should we choose your company?

A:1-A company with CE certificate certification.

2-Various production lines, flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine, various positioning pattern mask machine, customized machine according to the mask style you need.

3- Advanced technical support and strict quality control system.

4- Efficient and timely services such as email, WeChat, WhatsApp, etc.

Excerpted from the Internet, for reference only

The

reason

why

masks

can't

be

made

with

a

mask

machine

is

because

of

the

lack

of

the

core

material

of

masks:

meltblown

cloth.

What

is

a

meltblown

cloth?

Cut

a

used

medical

mask

and

you

will

find

that:

the

mask

has

three

layers,

(inner

layer)

moisture

absorption

layer,

(middle

layer)

core

filter

layer,

and

(outer

layer)

water

blocking

layer.

Because

according

to

the

national

production

regulations,

medical

masks

contain

at

least

3

layers

of

non-woven

fabrics

(N95

level

masks,

the

structure

has

been

optimized:

(middle

layer)

core

filter

layer

has

more

layers

and

thicker).

S

layer:

polypropylene

special

resin

(Sinopec)

-

nonwoven

fabric

factory

-

mask

factory

special

material)

-

meltblown

non-woven

fabric

factory

-

mask

factory.

Meltblown

cloth,

commonly

known

as

the

"heart"

of

the

mask,

is

the

filter

layer

in

the

middle

of

the

mask,

which

can

filter

bacteria

and

prevent

the

spread

of

germs.

Meltblown

cloth

is

a

kind

of

film

made

of

polypropylene

with

high

melt

index,

which

is

made

of

many

crisscross

fibers

stacked

in

random

directions.

one.

With

such

a

large

gap

in

the

meltblown

cloth,

how

does

it

filter

viruses

in

the

environment?

Although

the

size

of

the

new

coronavirus

is

very

small,

about

100

nanometers

(0.1

microns),

the

virus

cannot

exist

independently.

The

main

routes

of

transmission

are

secretions

and

droplets

when

sneezing.

The

size

of

the

droplets

is

about

5

microns,

which

is

the

First,

second,

the

meltblown

cloth

is

essentially

a

fiber

filter.

After

the

droplets

containing

the

virus

are

close

to

the

meltblown

cloth,

they

will

also

be

electrostatically

adsorbed

on

the

surface

and

cannot

be

penetrated.

Although

the

raw

materials

of

the

S

and

M

layers

of

the

mask

are

all

polypropylene

special

resins,

the

production

process

and

performance

of

the

special

materials

for

meltblown

cloth

and

other

non-woven

materials

are

very

different.

Meltblown

cloth

How

did

the

meltblown

cloth

come

from?

The

special

material

for

meltblown

cloth

is

polypropylene

with

high

melt

index.

The

higher

the

melt

index

of

polypropylene,

the

finer

the

melt-blown

fibers

and

the

better

the

filterability

of

the

melt-blown

cloth.