| Price | Negotiable |

| MOQ | 1 |

| Delivery Time | Negotiable |

| Brand | Envsin |

| Place of Origin | China |

| Certification | CE |

| Model Number | ET |

| Payment Terms | T/T, Western Union |

| Brand Name | Envsin | Payment Terms | T/T, Western Union |

| Temp. Range | -65℃ ~ +150 | Usage | Widely Used |

| Place of Origin | China | Minimum Order Quantity | 1 |

| Test Space Volume | 50L 100L 200L | Model Number | ET |

| Certification | CE | Temp. Constancy | ±0.3 ℃~±1.0 ℃ |

| Name | Thermal Shock Test Chamber | Test Zones | Two |

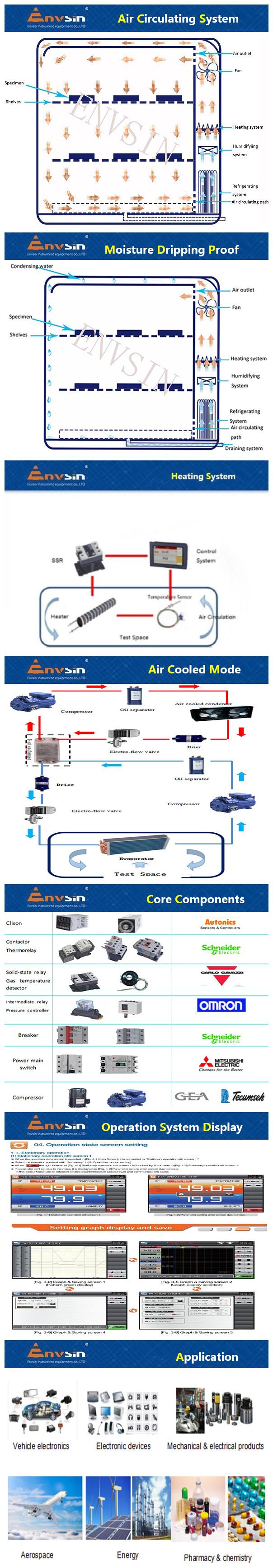

Features

|

★The Chamber is Fashion designed with modular construction |

★ Design with independent sensors to prevent specimens from damages caused by dewing, overheat, breezeless and smog |

|

★7'' colour touch screen with 32bit control system |

★ Intelligent and top-performance servo refrigerating control technology: energy saving and rapid heating/cooling rate. |

| ★ It can chose App mobility management | ★ The network video monitoring and data synchronization is optional |

| ★ The design of observation window with a reality visualization for real-time monitoring | ★ Automatic reminder of equipment maintenance plans and software of recording malfunction. |

| ★ Long defrosting cycles:over 700h's running before defrosting | ★ Unique operation mode: make testing area's temperature back to room temperature after tests are finished |

| ★ It can chose remote-assist service function and teaching CDs |

Specifications

| Model | ET450S2 | ET4100S2 | ET4200S2 |

| ET550S2 | ET5100S2 | ET5200S2 | |

| ET650S2 | ET6100S2 | ET6200S2 | |

| Test Space Volume (L) | 50 | 100 | 200 |

| Test Zones | 2 | ||

| Hot chamber Temp. Range (℃ ) | +50/+200 | ||

| Cold chamber Temp. Range (℃) | -80/70 | -80/70 | -75/70 |

| Temp. Constancy (℃ ) | ±0.3~±1.0 | ||

| Temp. Homogeneity (℃) | ±0.5~±2.0 | ±0.5~±2.0 | ±1.0~±2.0 |

| Recovery Time (min) | <1(on Air Outlet) | <5(on Air Outlet) | <5(on Air Outlet) |

| Test Space Dimension (mm) | 400W*400D*310H | 500W*500D*400H | 600W*550D*600H |

| External Dimension (mm) | 900W*2300D*2160H | 1000W*2400D*2250H | 1200W*2500D*2200H |

| Temperature Range(℃) | -40/150 | -40/150 | -40/150 |

| -55/150 | -55/150 | -55/150 | |

| -65/150 | -65/150 | -65/150 | |

| Cooling Methods | Air-Cooled Water-Cooled (IEC 60068-3-5) | ||

| Power | AC380V ±10%, 50HZ, 3/N/PE | ||

| Compliant with International Standards: | |||

| GB/T2423.22 | Test Na BS 2011 | ||

| MIL STD202F (Method 107G) | DIN40046, Test Na | ||

| IEC 60068-2-14 | JESD22-A101-A | ||

| Options | Standard Version |

| ☆ Independent sensors for specimen protection (NE60519-2.1993) | ☆ 2Stainless Steel shelves |

| ☆ Spare parts package | |

| ☆ E-management and cyber-software | |

| ☆ Video monitor system | |

| ☆ APP for mobility management | |

| ☆ 1 Entry port Φ100mm | |

| ☆ Nitrogen gas auxiliary device |