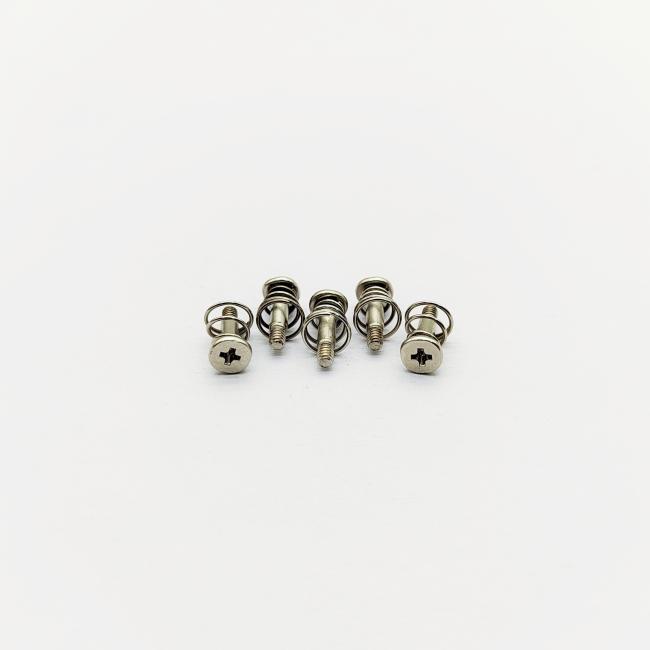

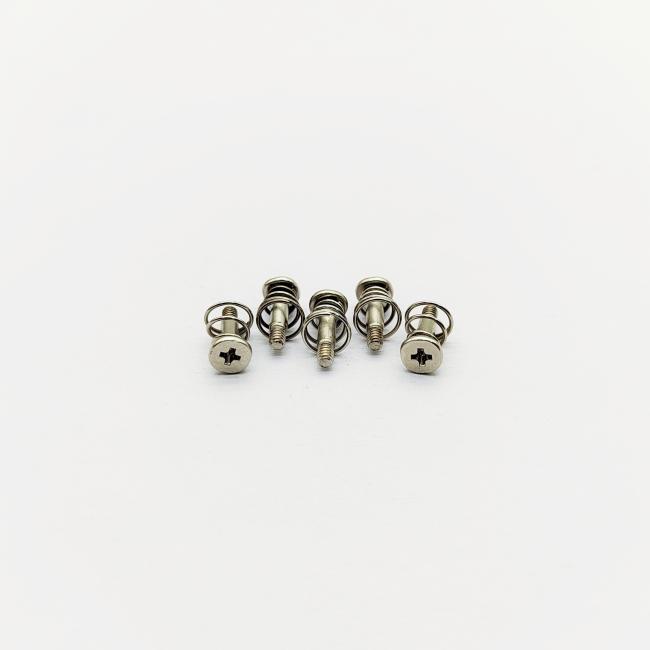

M2

Heatsink

Spring

Screws

10mm

Length

|

2.5mm

Thread

|

Phillips

Drive

|

Zinc

Phosphate

Premium

M2

heatsink

spring

screws,

10mm

overall

length,

2.5mm

thread.

Zinc

phosphate

coating

for

corrosion

resistance.

Ensures

optimal

mounting

pressure

for

compact

electronics

cooling.

Custom

options

available.

Our

M2

Heatsink

Spring

Screws

are

engineered

for

applying

consistent

and

reliable

clamping

pressure

in

compact

thermal

management

solutions.

The

integrated

spring

mechanism

automatically

compensates

for

thermal

expansion,

component

height

tolerances,

and

prevents

PCB

damage

from

over-torquing.

This

ensures

optimal

thermal

contact

between

the

heatsink

and

sensitive

components

(e.g.,

RAM

chips,

SSDs,

small

form-factor

ICs),

critical

for

effective

heat

dissipation

and

long-term

device

reliability.

Technical

Specifications

|

Total

Length

|

10.0

mm

(±0.1mm)

|

|

Thread

Length

|

2.5

mm

(±0.1mm)

|

|

Thread

Diameter

|

M2

(Metric)

|

|

Drive

Type

|

Cross

Recess

(Phillips

#0

or

#1)

|

|

Head

Style

|

Pan

Head

|

|

Material

|

High-Carbon

Steel

(Grade

4.8/8.8/10.9

available)

|

|

Spring

Material

|

Stainless

Steel

(Grade

304)

|

|

Surface

Treatment

|

Zinc

Phosphate

Coating

(Phosphating)

|

|

Customization

|

Various

lengths,

platings

(Zn,

Ni),

materials

(Stainless

Steel),

drive

types

(Pozidriv,

Torx)

available

|

Applications

&

Uses

These

miniature

spring

screws

are

specifically

designed

for

securing

heatsinks

in

space-constrained

electronic

applications

where

precise

pressure

is

vital:

-

Computer

Hardware:

Mounting

heatsinks

on

M.2

NVMe

SSDs,

RAM

modules,

chipset

controllers,

and

small

form-factor

motherboard

components.

-

Consumer

Electronics:

Securing

thermal

solutions

in

laptops,

tablets,

gaming

consoles,

routers,

and

set-top

boxes.

-

Telecommunications

Equipment:

Fastening

heatsinks

on

network

interface

cards,

optical

modules,

and

RF

components.

-

Power

Management:

Cooling

for

voltage

regulators

and

power

ICs

on

densely

packed

PCBs.

-

LED

Applications:

Attaching

small

heatsinks

to

high-power

LED

packages.

Our

Advantages

-

More

than

20

years

of

screw

production

experience

and

non-standard

screw

custom

development

experience,

providing

cost-effective

solutions

for

your

fastener

supply

chain.

-

Precise

production

equipment

with

imported

machinery

from

Taiwan

to

produce

precision

screws

and

hardware

accessories.

Free

sample

testing

available

for

compatibility

verification.

-

Complete

quality

management

system

with

multiple

strict

monitoring

checks

for

every

production

batch.

-

Dedicated

account

management

for

seamless

collaboration

and

system-supporting

services.

Support

and

Services

Our

team

of

knowledgeable

professionals

provides

comprehensive

support

services

for

all

aspects

of

our

spring

screws,

including:

-

Selection

advice

to

ensure

you

have

the

right

type

and

size

for

your

project

-

Guidance

on

proper

installation

techniques

-

Detailed

product

specifications

and

material

safety

data

sheets

-

Step-by-step

installation

guides

and

troubleshooting

assistance

-

Maintenance

tips

and

best

practices

to

extend

product

life

Packing

and

Shipping

Our

spring

screws

are

carefully

packaged

to

ensure

safe

delivery:

-

Individually

packed

in

moisture-resistant

plastic

bags

within

sturdy

cardboard

boxes

-

Proper

cushioning

to

prevent

movement

during

transit

-

Clear

labeling

with

product

information

for

easy

identification

-

Palletized

and

shrink-wrapped

for

bulk

orders

-

Reliable

courier

services

with

tracking

information

provided

Our

factory

accepts

customized

drawings.

Please

contact

us

if

you

need

to

highlight

specific

certifications

or

other

parameters

in

the

product

description.