| Price | Negotiable |

| MOQ | 50000 |

| Delivery Time | 15-20 work days |

| Brand | guanbiao |

| Place of Origin | China |

| Certification | ISO9001 |

| Model Number | Customizable |

| Packaging Details | Plastic bag + carton + pallet |

| Payment Terms | T/T |

| Supply Ability | 5000000 |

| Lead Time | 15~20 working days | Place of Origin | China |

| Packaging Details | Plastic bag + carton + pallet | Material | Stainless Steel |

| Finsh | Yellow Zinc Plating** (Smooth Finish, Tri-valent Chromate) | Dimension | We Can Customise to your dimension |

| Model Number | Customizable | Supply Ability | 5000000 |

| Certification | ISO9001 | Tolerant | +/- 0.05mm |

| Brand Name | guanbiao | Payment Terms | T/T |

| Installation Method | Riveting | Panel Thickness | 3.0 - 8.0 mm |

| Price | Negotiable | Delivery Time | 15-20 work days |

| Minimum Order Quantity | 50000 | Product Application | Heavy Equipment |

| Head Style | Flat |

| Attribute | Value |

|---|---|

| Product Application | Heavy Equipment |

| Head Style | Flat |

| Lead Time | 15~20 working days |

| Finish | Yellow Zinc Plating (Smooth Finish, Tri-valent Chromate) |

| Installation Method | Riveting |

| Material | Stainless Steel |

| Tolerance | +/- 0.05mm |

| Dimension | We Can Customize to your dimension |

| Panel Thickness | 3.0 - 8.0 mm |

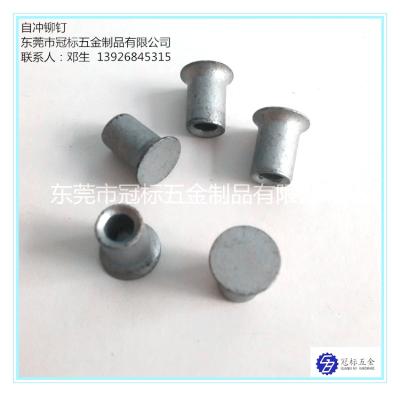

Long-length blind hole rivet nut columns for thicker materials. Stainless steel with yellow zinc plating, deep serrations. M6-M12 sizes. For heavy equipment, transportation, & energy. Custom specs.

Designed for demanding applications requiring penetration through thicker materials or higher strength, our Heavy-Duty Blind Hole Rivet Nut Columns feature a reinforced design. They incorporate deeper serrations under the 90° flat head for maximum anti-rotation performance in high-vibration environments.

| Head Type | 90° Flat Head with Reinforced Serrated Knurl |

| Head Diameter (D) | M6: 12.0mm; M8: 15.0mm; M10: 18.0mm; M12: 22.0mm |

| Shank Diameter | M6, M8, M10, M12 |

| Total Length (L) | M6: 20-40mm; M8: 25-50mm; M10: 30-60mm; M12: 40-80mm (Extended Range) |

| Blind Hole Depth | ≈65-70% of Total Length (L) |

| Thread Depth (T) | ≈55-60% of Total Length (L) (Non-Full Thread Design) |

| Material | A2-80 or A4-80 (316) Stainless Steel (Optional) |

| Surface Treatment | Yellow Zinc Plating (Smooth Finish, Tri-valent Chromate) |

| Installation Force | M8: 20-25 kN; M10: 30-38 kN |

| Torque-Out Resistance | M8: ≥20 Nm; M10: ≥30 Nm |

| Panel Thickness | 3.0 - 8.0 mm |

| Customization | Custom lengths, materials |

Our team provides comprehensive support including product selection advice, installation guidance, and troubleshooting assistance. We offer detailed specifications, material safety data sheets, and maintenance tips to ensure optimal performance.

Products are securely packaged in moisture-resistant bags within sturdy boxes. Larger orders are palletized and shrink-wrapped. We use reliable courier services with tracking information provided for all shipments.