| Price | Negotiable |

| MOQ | 50000 |

| Delivery Time | 15-20 work days |

| Brand | guanbiao |

| Place of Origin | China |

| Certification | ISO9001 |

| Model Number | Customizable |

| Packaging Details | Plastic bag + carton + pallet |

| Payment Terms | T/T |

| Supply Ability | 5000000 |

| Lead Time | 15~20 working days | Place of Origin | China |

| Packaging Details | Plastic bag + carton + pallet | Material | Stainless Steel |

| Finsh | Blue-White Zinc Plating** (Smooth Finish) | Dimension | We Can Customise to your dimension |

| Model Number | Customizable | Supply Ability | 5000000 |

| Certification | ISO9001 | Tolerant | +/- 0.05mm |

| Brand Name | guanbiao | Payment Terms | T/T |

| Installation Method | Riveting | Panel Thickness | 2.0 - 6.0 mm (Ideal) |

| Price | Negotiable | Delivery Time | 15-20 work days |

| Minimum Order Quantity | 50000 | Product Application | Engineering Machinery |

| Head Style | Flat |

| Attribute | Value |

|---|---|

| Product Application | Engineering Machinery |

| Head Style | Flat |

| Lead Time | 15~20 working days |

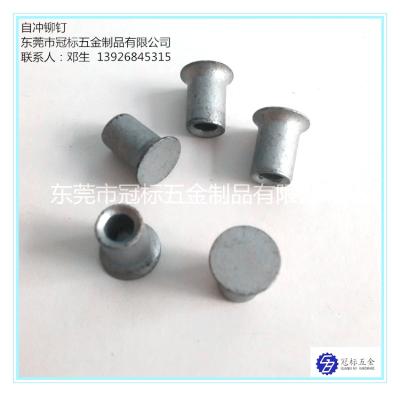

| Finish | Blue-White Zinc Plating (Smooth Finish) |

| Installation Method | Riveting |

| Material | Stainless Steel |

| Tolerance | +/- 0.05mm |

| Dimension | We Can Customize to your dimension |

| Panel Thickness | 2.0 - 6.0 mm (Ideal) |

High-strength blind hole rivet nut columns for heavy-duty applications. A2/A4 SS, deep serrations, thick walls. Blue-white zinc plating. M5-M12. For power, telecom, & machinery. Custom specs available.

Designed for demanding industrial environments, our Heavy-Duty Flat Head Blind Hole Rivet Nut Columns feature deeper and larger serrations under the head and a thicker wall structure to withstand extreme vibrational forces, higher torque loads, and repeated assembly/disassembly. Made from higher-strength A2-80 or A4-80 (316) stainless steel and finished with blue-white zinc plating, these nuts provide superior push-out and torque-out strength for critical applications in energy, transportation, and heavy machinery. The blind hole design is essential for sealing out moisture and contaminants.

| Head Type | 90° Flat Head with Reinforced Serrated Knurl |

| Head Diameter (D) | M6: 12.0mm; M8: 15.0mm; M10: 18.0mm; M12: 22.0mm |

| Total Length (L) | 10mm - 50mm (e.g., M8x20mm, M10x30mm) |

| Blind Hole Depth | ≈65-70% of Total Length (L) |

| Thread Depth (T) | ≈55-60% of Total Length (L) (Non-Full Thread Design) |

| Material | A2-80 or A4-80 (316) Stainless Steel (Optional) |

| Surface Treatment | Blue-White Zinc Plating (Smooth Finish) |

| Panel Thickness | 2.0 - 6.0 mm (Ideal) |

| Customization | Custom lengths, materials, serration patterns |

Our team of knowledgeable professionals provides comprehensive support services for all aspects of our Stainless Steel Rivet Nuts, including:

Our Stainless Steel Rivet Nuts are packaged with care to ensure they arrive in perfect condition: