Stainless

Steel

Flat

Head

Blind

Hole

Rivet

Nut

M3-M8

Zinc

Plated

Product

Description

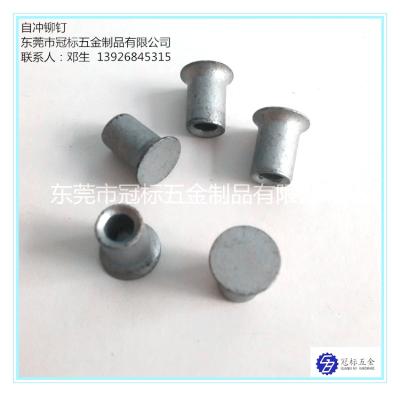

Flat

Head

Blind

Hole

Press-in

Rivet

Nut

Column

-

Serrated

Knurl

-

for

Electronics

Enclosures

-

M3

to

M8

-

Zinc

Plated

Flush-mount

blind

hole

rivet

nut

columns

for

thin

sheets.

A2-70

SS,

serrated

underhead

for

anti-rotation,

non-full

internal

thread.

Blue-white

zinc

plating.

M3-M8

sizes.

For

servers,

cabinets,

&

appliances.

Custom

lengths.

Our

Flat

Head

Blind

Hole

Pressure

Rivet

Nut

Columns

provide

strong,

reliable

threaded

points

in

thin

metal

panels

where

a

clean,

flush

finish

is

critical.

The

90°

countersunk

head

sits

perfectly

flat

with

the

surface,

while

the

serrated

knurl

(flower

teeth)

under

the

head

bites

into

the

material,

preventing

rotation

during

installation

and

use.

Manufactured

from

A2-70

(304)

stainless

steel

and

finished

with

a

smooth

blue-white

zinc

plating,

they

offer

a

cost-effective

solution

with

good

corrosion

resistance

for

indoor

applications.

The

blind

hole

(non-through

hole)

and

non-full

thread

design

protect

threads

from

damage

during

installation

and

prevent

debris

ingress.

Technical

Specifications

|

Head

Type

|

90°

Flat

Head

(Countersunk)

with

Serrated

Knurl/Flower

Teeth

|

|

Head

Diameter

(D)

|

M3:

6.0mm;

M4:

8.0mm;

M5:

9.5mm;

M6:

11.0mm

|

|

Total

Length

(L)

|

6mm

-

25mm

(e.g.,

M4x10mm,

M6x15mm)

|

|

Blind

Hole

Depth

|

≈70-75%

of

Total

Length

(L)

|

|

Thread

Depth

(T)

|

≈60-65%

of

Total

Length

(L)

(Non-Full

Thread

Design)

|

|

Material

|

A2-70

Stainless

Steel

(304)

|

|

Surface

Treatment

|

Blue-White

Zinc

Plating

(Smooth

Finish)

|

|

Panel

Thickness

|

1.0

-

3.0

mm

(Ideal)

|

|

Customization

|

Knurl

depth/angle,

thread

percentage

|

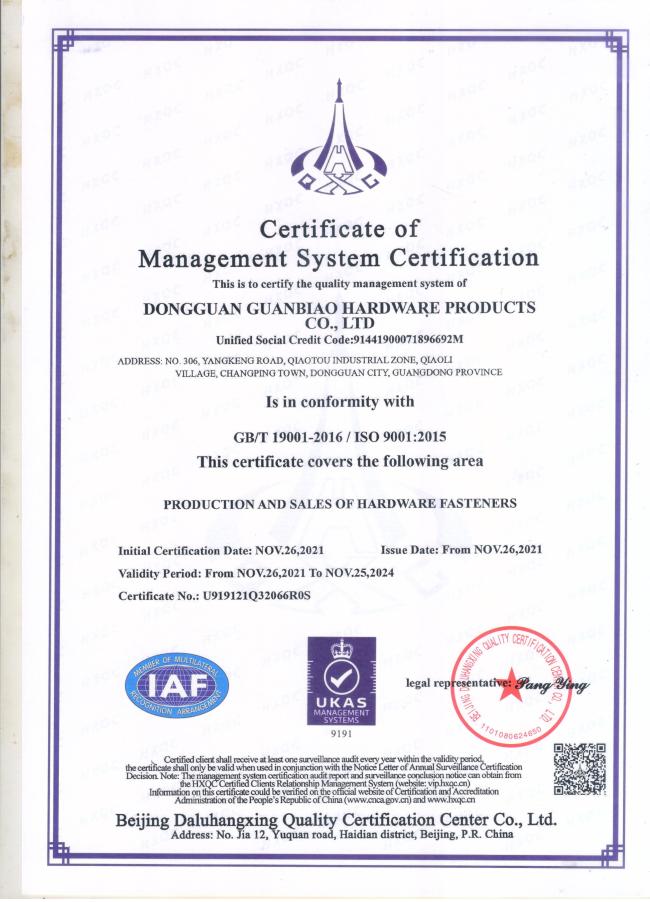

Our

factory

is

able

to

accept

customized

drawings.

To

strike

a

balance

between

technical

details

and

customer-centric

messaging,

please

let

us

know

if

you

need

to

tweak

the

description

to

highlight

specific

certifications

or

other

parameters!