316L

Flat

Head

Semi-Tubular

Rivets

-

Medical/Marine

Grade

-

Electropolished

-

ISO

15977

-

Ø2mm

To

Ø5mm

|

Attribute

|

Value

|

|

Product

Application

|

Electronics

chassis

assembly

|

|

Head

Style

|

Flat

|

|

Thread

|

No

|

|

Lead

Time

|

15~20

working

days

|

|

Finish

|

Passivation

(Matte

Grey)

|

|

Installation

Method

|

Riveting

|

|

Material

|

Stainless

Steel

|

|

Tolerance

|

+/-

0.05mm

|

|

Dimension

|

We

Can

Customise

to

your

dimension

|

|

Shear

Strength

|

M6:

3,200N

(ISO

15998)

|

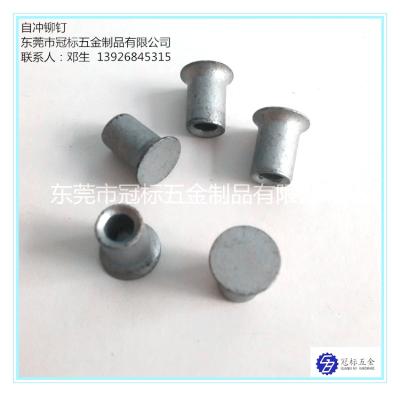

High-Precision

Semi-Tubular

Rivets

for

Harsh

Environments

These

medical/marine

grade

semi-tubular

rivets

are

precision-machined

from

A4-80

stainless

steel

(316L)

with

electropolished

finish

(Ra<0.2µm).

Featuring

±0.03mm

diameter

tolerance

and

controlled

hollow

depth,

they

deliver

consistent

performance

in

surgical

instruments,

marine

hardware,

and

food

processing

equipment.

Technical

Specifications

Head

Type:

100°

Flat

Head

(ISO

15977)

Head

Diameter

(D):

Ø3.2mm

(Ø2mm),

Ø6.0mm

(Ø4mm)

Total

Length

(L):

4-15mm

(e.g.,

Ø3mm:

5/6/8/10/12mm)

Hollow

Depth

(H):

1.2-1.8×d

(Customizable)

Hole

Diameter

(d):

Ø1.2mm

(Ø2mm),

Ø2.0mm

(Ø4mm)

Material:

4-80

Stainless

Steel

(316L)

Surface

Treatment:

Passivation

+

Electropolishing

(Ra

0.1-0.2µm)

Diameter

Tolerance:

±0.03mm

Customization:

Bio-compatible

coatings,

laser

marking

Primary

Uses

&

Applications

-

Surgical

instrument

assembly

-

Marine

deck

fittings

-

Pharmaceutical

packaging

machines

-

Desalination

plant

equipment

-

Dairy

processing

conveyors

Installation

Instructions

-

Ultrasonic

clean

rivets

before

installation.

-

Use

precision

micro-riveter

with

force

control.

-

Set

compression

force:

-

Ø3mm:

150-200N

-

Ø5mm:

400-500N

-

Inspect

under

10x

magnification

for

flush

seating.