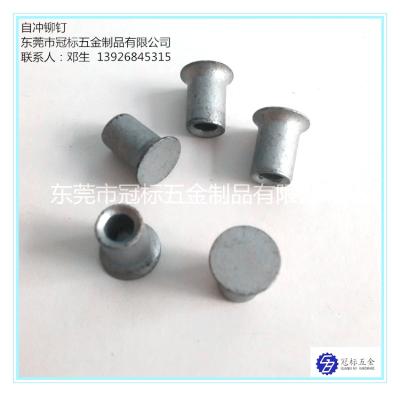

304

SS

Flat

Head

Semi-Tubular

Rivets

-

100°

Countersunk

-

DIN

7337

-

M3

To

M6

Sizes

-

Passivated

Product

Attributes

|

Attribute

|

Value

|

|

Product

Application

|

Electronics

chassis

assembly

|

|

Head

Style

|

Flat

|

|

Thread

|

No

|

|

Lead

Time

|

15~20

working

days

|

|

Finish

|

Passivation

(Matte

Grey)

|

|

Installation

Method

|

Riveting

|

|

Material

|

Stainless

Steel

|

|

Tolerance

|

+/-

0.05mm

|

|

Dimension

|

We

Can

Customize

to

your

dimension

|

|

Grip

Range

|

0.5-4.0mm

|

Product

Description

Corrosion-resistant

semi-tubular

rivets

with

100°

flat

head.

304

stainless

steel,

hollow

depth

1.5D.

Sizes:

Ø3-6mm.

Passivated

finish.

For

electronics,

machinery

&

automotive

applications.

Custom

lengths

available.

Achieve

flush-surface

fastening

with

DIN

7337

compliant

semi-tubular

rivets

featuring

a

precision

100°

flat

head

and

controlled

hollow

depth

(1.5×

shank

diameter).

Made

from

A2-70

stainless

steel

(304),

these

rivets

provide

reliable

clinching

force

for

sheet

metal,

plastics,

and

leather

assemblies.

Passivated

finish

ensures

corrosion

resistance

in

industrial

environments.

Technical

Specifications

|

Head

Type

|

100°

Flat

Head

(Countersunk)

|

|

Head

Diameter

(D)

|

Ø4.8mm

(Ø3mm

rivet),

Ø7.2mm

(Ø5mm

rivet)

|

|

Total

Length

(L)

|

6-20mm

(e.g.,

Ø4mm:

6/8/10/12/15mm)

|

|

Hollow

Depth

(H)

|

1.5×d

(e.g.,

Ø4mm

rivet

=

6mm

hollow)

|

|

Hole

Diameter

(d)

|

Ø1.8mm

(Ø3mm),

Ø2.4mm

(Ø5mm)

|

|

Material

|

A2-70

Stainless

Steel

(304)

|

|

Surface

Treatment

|

Passivation

(Matte

Grey)

|

|

Grip

Range

|

0.5-4.0mm

|

|

Customization

|

Non-standard

L/h

ratios,

special

diameters

|

Primary

Uses

&

Applications

-

Electronics

chassis

assembly

-

Automotive

interior

trim

-

Machinery

guards

&

covers

-

Leather

goods

&

luggage

hardware

-

Signage

mounting

systems

Installation

Instructions

-

Drill

hole

=

shank

diameter

(e.g.,

Ø4mm

hole

for

Ø4mm

rivet)

-

Insert

rivet

through

materials

-

Place

flat

die

under

head

-

Use

rivet

setter

to

compress

hollow

end

into

1.5D

mushroom

shape

-

Verify

flush

head

seating