316

SS

Heavy

Duty

Semi-Tubular

Rivets

-

20%

Thicker

Walls

-

Flat

Head

-

Marine

Grade

-

M4

to

M10

Product

Attributes

|

Shear

Strength

|

M6:

3,200N

(ISO

15998)

|

|

Product

Application

|

Electronics

chassis

assembly

|

|

Head

Style

|

Flat

|

|

Thread

|

No

|

|

Lead

Time

|

15~20

working

days

|

|

Finish

|

Passivation

+

Electropolishing

(Ra

0.3µm)

|

|

Installation

Method

|

Riveting

|

|

Material

|

Stainless

Steel

|

|

Tolerance

|

+/-

0.05mm

|

|

Dimension

|

We

Can

Customize

to

your

dimension

|

Product

Description

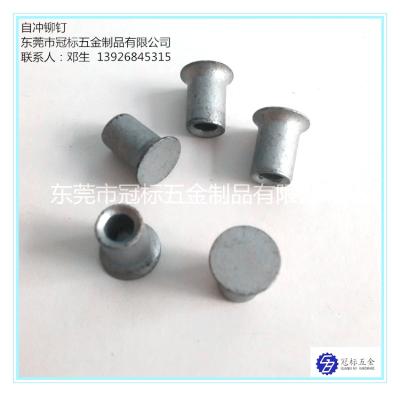

Extra-strength

marine

semi-tubular

rivets.

316

stainless

steel,

120°

flat

head,

hollow

depth

1.25D.

Withstands

1000hrs

salt

spray.

Sizes

M4-M10.

Electropolished.

Custom

specs.

Engineered

for

corrosive

environments,

these

A4

stainless

semi-tubular

rivets

feature

20%

thicker

walls

and

a

reduced

hollow

depth

(1.25D)

for

maximum

shear

strength.

The

electropolished

finish

provides

superior

saltwater

resistance,

making

them

ideal

for

marine,

chemical,

and

offshore

applications.

Technical

Specifications

|

Head

Type

|

Flat

Head

(120°±2°)

|

|

Head

Diameter

(D)

|

M4:

8.2mm;

M6:

11.5mm;

M8:

15.0mm;

M10:

18.0mm

|

|

Total

Length

(L)

|

M4:

8-25mm;

M6:

12-40mm;

M10:

20-60mm

|

|

Hollow

Depth

(H)

|

1.5D

(e.g.,

M4:

6.0mm)

|

|

Hole

Diameter

(d)

|

1.25D

(e.g.,

M6:

7.5mm)

|

|

Material

|

A4-80

Stainless

Steel

(316L)

|

|

Surface

Treatment

|

Passivation

+

Electropolishing

(Ra

0.3µm)

|

|

Shear

Strength

|

M6:

3,200N

(ISO

15998)

|

|

Customization

|

Custom

H/L

ratios,

specialized

alloys

|

Primary

Uses

&

Applications

-

Boat

deck

hardware

-

Offshore

platform

ladders

-

Chemical

tank

seals

-

Coastal

signage

frames

-

Saltwater

pump

assemblies

How

to

Use

-

Pre-drill

hole

to

exact

diameter

(e.g.,

Ø6.05mm

for

M6).

-

Use

hydraulic

riveter

with

semi-tubular

die

set.

-

Apply

pressure:

-

Form

compact

flange

(0.8-1.0D

width).