| Price | USD 1,500 ~ 95,000 / set |

| MOQ | 1 |

| Delivery Time | 5-8 work days |

| Brand | DAWSON |

| Place of Origin | China |

| Certification | CE |

| Model Number | M-20L |

| Packaging Details | Standard Export Packing |

| Payment Terms | L/C, T/T |

| Supply Ability | 20 set/month |

| Usage | injection molding machine | Place of Origin | China |

| Packaging Details | Standard Export Packing | Product Name | caps,lids,preforms,covers... |

| Mould Life | more than 1,000,000 times | Model Number | M-20L |

| Supply Ability | 20 set/month | Certification | CE |

| Logo | Custom Logo Available | Brand Name | DAWSON |

| Payment Terms | L/C, T/T | Product Material | Aluminium |

| Cavity | Single Cavity\ Multiple Cavity | Price | USD 1,500 ~ 95,000 / set |

| Delivery Time | 5-8 work days | Volume | 100ML-300L |

| Samples | Send according to customer's requirement | Minimum Order Quantity | 1 |

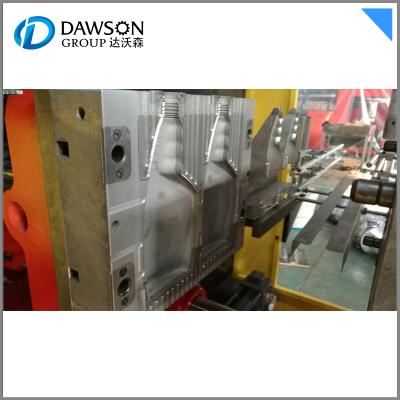

Plastic daily chemical bottle molding mold Good Price blowing machine mould

Below is the general information and policy for our OEM/ODM plastic injection mold:

| Detailed info for mould steel | ||

| Mould material | Hardness | Mould life |

| P20 | HRC 28-33 | >300,000 shots |

| 718 | HRC 33-36 | >500,000 shots |

| H13 | HRC >43 | >800,000 shots |

| 2344 | HRC >48 | >800,000 shots |

| S136 | HRC 48-52 | >1,000,000 shots |

| Quantity(Sets) | 1 - 1 | >1 |

| Est. Time(day) | 45 | To be negotiated |

| Description of DAWSON Plastic Injection Mould | |

| Mould material | 45#, P20, H13, 718, 2738, NAK80, S136, CENA-1 etc. |

| Mould base | LKM, HASCO etc. |

| Standard Component | DME, HASCO, JIS etc. |

| Cavity | single/multi |

| Runner | hot/cold |

| Mould life | 50,0000-5,000,000shots |

| Design software | UG, PROE, CAD, SolidWorks etc. |

| Plastic material | PP, PC, PE, PS, PU, ABS, PVC, PA, POM, PMMA, PET, PPR etc. |

| Delivery time | 45--60days |

| Package | Wooden Case |

| Delivery | By Sea |

| Specifications | Depends on customer's requirements |

| Process Machine | CNC, High Speed Carve, EDM, Wire Cut, Driller, Grinder, fly cutter etc. |

DAWSON Mould Trade Process:

| 1. Quote | According to sample, drawing and specific requirement. |

| 2. Discussion | Mold material, cavity number, price, runner, payment, etc. |

| 3. S/C Signature | Approval for all the items |

| 4. Advance | Pay 50% by T/T |

| 5. Product Design Checking | Our engineers will check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| 6. Mould Design | We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

| 7. Mold Tooling | We start to make mold after mold design confirmed |

| 8. Mold Processing | Send report to customer once each week |

| 9. Mold Testing | Send trial samples and try-out report to customer for confirmation |

| 10. Mold Modification | According to customer's feedback |

| 11. Balance settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| 12. Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Why choose us?

| 1. | Best design,competitive price |

| 2. | More than 10 years experience in this field |

| 3. | Professional in design & making plastic mould |

| 4. | One stop solution |

| 5. | On time delivery |

| 6. | Best after-sale service |

| 7. | Specialized in all kinds of plastic injection moulds |