| Price | 23000 USD/PCS |

| MOQ | 1 |

| Delivery Time | 45-60 work days |

| Brand | DAWSON |

| Place of Origin | China |

| Certification | CE |

| Payment Terms | T/T, L/C |

| Condition | New | Place of Origin | China |

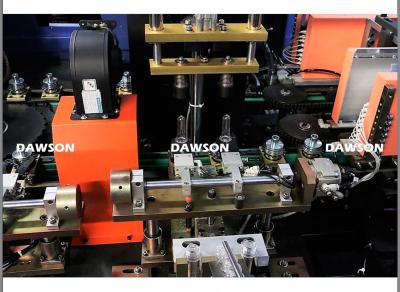

| PLC | Mitsubishi | Product Name | Pet Bottle Blow Molding Machine |

| Blowing Cylinder | Festo | Controlled by | PLC |

| Certification | CE | Brand Name | DAWSON |

| Payment Terms | T/T, L/C | Cavities | 2, 4, 6, 8, 10, 12 |

| Price | 23000 USD/PCS | Delivery Time | 45-60 work days |

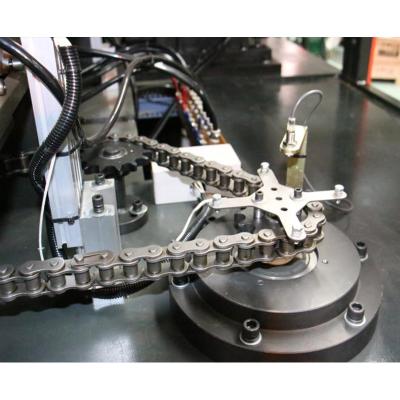

| Minimum Order Quantity | 1 | Revolve Cylinder | SMC |

| Application | Beverage Bottle, Oil Bottle | Technical Service | 24 Hours/365 Days Online |

| Automatic | Fully Automatic |

Beverage companies have two pressing needs for bottle blowing equipment. One is due to the continuous rise in the price of plastic raw materials, beverage companies are always thinking about how to reduce packaging costs to maximize profits, therefore, it is necessary to use advanced bottle blowing equipment to produce lighter bottles

In general, according to their own needs of the product to choose the model of the bottle blowing machine. For different amounts of manufacturers, the general concern is a few cavities, the size of the bottle capacity, and the output per hour.

PET Blow Molding Machine is a Machine that blows bottles. The simplest explanation is a Machine that blows plastic particles (softened into a liquid) or preformed embryos into a bottle through a process. The bottle blowing machine is convenient and quick, and the forming quantity is large. It replaces most of the manual bottle blowing and is adopted by most beverage enterprises.

Good Quality Multi Chamber Pet Bottle Making Machinery Blow Molding Machine

Products Description

equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

Small performs distance heating system

Heater

distance

in

the

heating

oven

is

reduced

to

38mm,

compared

with

the

conventional

heating

oven

it

saves

more

than

30%

electricity

consumption.

Equipped

with

the

air

cycling

system

and

redundant

heat

discharge

system,

it

ensures

the

constant

temperature

of

the

heating

zone.

Efficient and soft perform inlet system

By rotary and soft preform inlet system, the speed of preform feeding is ensured meanwhile, the preform neck is well protected.

Professional Workshop

Our Professional Injection Stretch Blow Molding Machine Workshop...

Company Profile