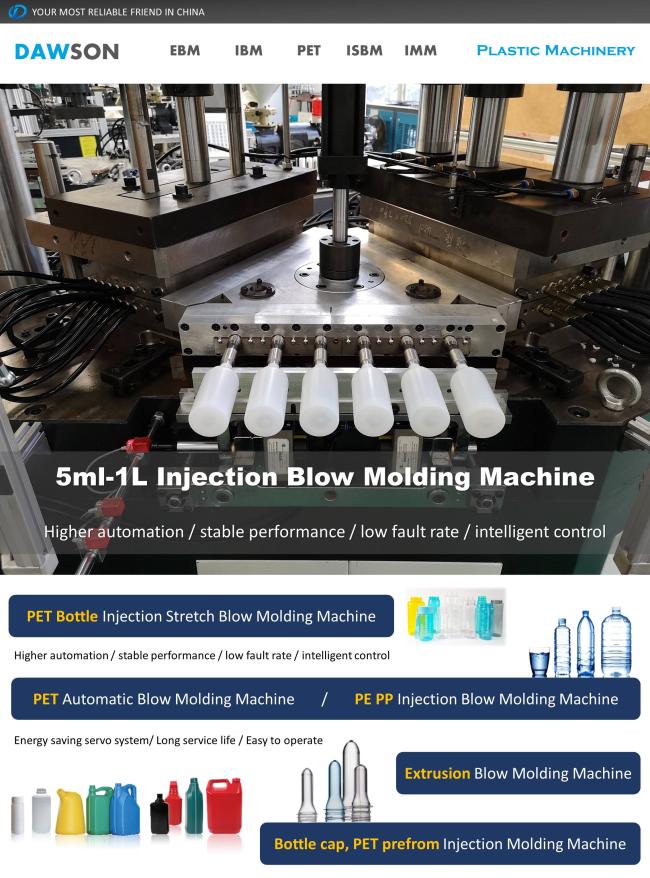

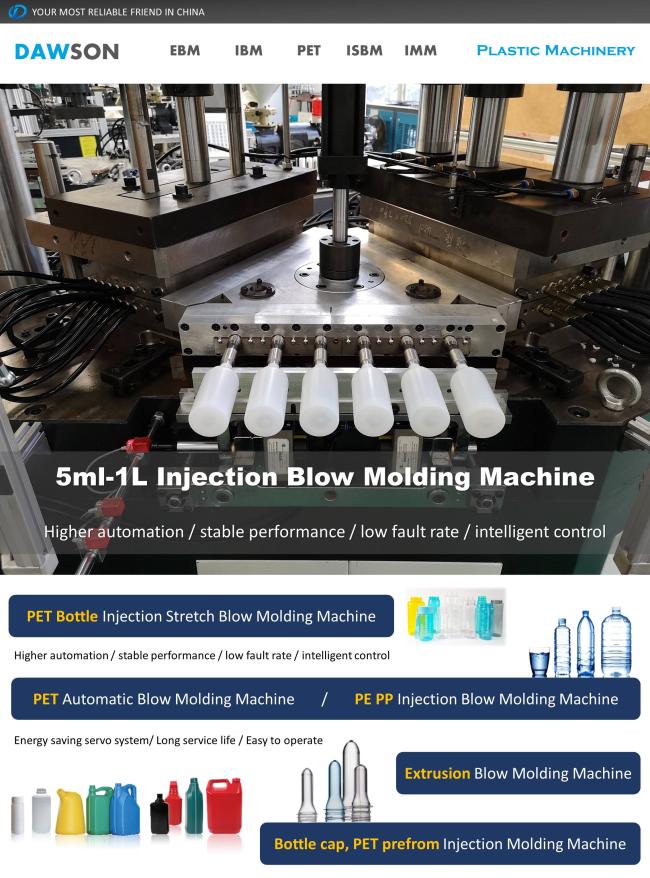

Servo

System

IBM

500ml

Bottle

Injection

Blow

Molding

Machine

At

present,

more

and

more

people

in

China

have

begun

to

pay

attention

to

the

research

and

development

of

high-speed

extruders.

In

particular,

in

recent

years,

high-speed

extruders

have

made

great

progress,

plastic

extruders

are

the

development

of

high-speed

extrusion

technology

and

have

been

applied

more

and

more

widely.

With

the

continuous

demand

of

output

and

energy

consumption,

high-speed

extruder

has

become

one

of

the

development

directions

of

extruder.

DAWSON

MACHINERY

&

MOULD

GROUP

.jfif)

Technical

Parameters

|

|

|

|

|

|

Item

|

|

Unit

|

|

|

Injection

system

|

Screw

Diameter

|

mm

|

40

|

45

|

50

|

|

Max.

Theoretical

injection

capacity

|

G

|

176

|

260

|

314

|

|

Heating

capacity

|

KW

|

7.2

|

10

|

10

|

|

No.

of

heating

area

|

Qty

|

3

|

3

|

3

|

|

Clamping

&

blowing

system

|

Clamping

force

of

injection

|

kn

|

350

|

450

|

650

|

|

Clamping

force

of

blowing

|

kn

|

40

|

78

|

89

|

|

Opening

stroke

of

mold

platen

|

mm

|

120

|

120

|

140

|

|

Max.

Platen

size

(L×W)

|

mm

|

420×340

|

560×390

|

740×390

|

|

Min.

Mold

thickness

(H)

|

mm

|

180

|

240

|

280

|

|

Heating

capacity

of

mould

|

KW

|

2.8

|

4.0

|

5.0

|

|

Product

dimension

range

|

Suitable

bottle

range

|

ml

|

3-800

|

3-800

|

5-800

|

|

Max.

bottle

height

|

mm

|

≤180

|

≤200

|

≤200

|

|

Max.

Dia.

of

bottle

|

mm

|

≤80

|

≤80

|

≤80

|

|

Dry

cycle

|

s

|

4

|

|

|

|

Hydraulic

driving

system

|

Motor

power

|

KW

|

11/15

|

18.7/22

|

17

|

|

hydraulic

pressure

|

Mpa

|

14

|

14

|

14

|

|

Pneumatic

system

|

Min.

Air

pressure

|

Mpa

|

≥0.8

|

1.0

|

1.0

|

|

Discharge

rate

of

compressed

air

|

M3/mm

|

≥0.7

|

≥0.8

|

≥0.8

|

|

Cooling

system

|

Water

flowage

|

M3/h

|

3

|

3

|

4

|

|

|

Total

rated

power

with

mold

heating

|

KW

|

21/25

|

34/38

|

45

|

|

Machine

information

|

Dimension

|

M

|

3.1×1.2×2.2

|

3.5×1.4×2.3

|

4×1.28×2.35

|

|

machine

weight

|

Ton

|

4.0

|

6.0

|

7.5

|

Machine

Advantages

Bottle

is

a

container

that

can

hold

liquid

or

solid,

which

can

be

seen

everywhere

in

our

life,

including

medicine

bottle,

cosmetics

bottle

and

beverage

bottle.

Due

to

the

rapid

development

of

the

petroleum

industry,

human

beings

invented

high

molecular

polymer,

which

is

commonly

known

as

plastics.

Since

then,

our

bottle

materials

have

changed

from

single

glass

or

ceramics

to

various

kinds

of

plastics.

Feature

*

Excellent

plasticizing

unit

*

Bridge

clamping

unit

for

synchronism

mould

open/close,

cycle

time

less

*

Servo

system

can

save

35

to

40%

energy

compared

to

normal

system

*

Servo

rotary,

precise,

long

using

time,

easy

maintenance,

save

energy.

*

Optional

injection

with

all-electric

way,

replacing

hydraulic

way

*

CE

certificate

|

our

own

engineers

team,

we

have

more

then

18

years

experience

in

this

field.

1.

The

servo

motor

of

our

machine

uses

PHASE

from

Italy,

it

is

the

best

supplier

of

servo

motors.

2.

The

cylinder

drive

has

been

upgraded

to

a

single

cylinder,

which

is

more

stable

and

stronger.

Life

is

also

longer

than

the

others.

|

Our

pneumatic

valve

uses

FESTO

Germany,

which

is

the

first

quality

in

the

world.

Its

purchase

cost

itself

is

very

high,

but

the

quality

is

very

stable

and

the

service

life

is

very

long.

|

|

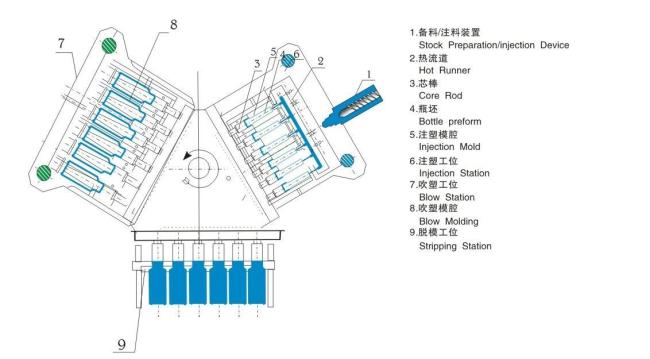

Injection

blow

plastic

bottles

are

molded

from

raw

materials

to

finished

products

in

one

step,

with

a

high

degree

of

automation,

no

need

of

manual

secondary

processing,

labor

saving,

hygienic

and

in

line

with

the

GMP

requirements

of

pharmaceutical

packaging.

It

is

especially

suitable

for

the

production

of

pharmaceutical

bottles,

juice,

beverage,

milk

bottles

and

cosmetic

bottles

and

other

industries

with

higher

bottle

requirements.

Professional

Workshop

Our

Professional

Injection

Blow

Molding

Machine

Workshop...

Company

Profile

DAWSON

MACHINE

&

MOULD

GROUP

located

in

Zhangjiagang

city,

have

more

than

18

years'

experience

in

the

field

of

plastic

machinery,

blow

molding

machine,injection

blow

molding

machine,

injection

molding

machine,

PET

blow

molding

machine,

injection

stretch

blow

molding

machine

during

the

past

18

years,

we

always

force

our

energy

into

new

areas

of

plastic

machinery,

plastic

packaging

machinery,

to

update

the

technology,

to

learn

advanced

experience,

to

confirm

new

theory

and

new

design,

we

are

forming

a

unique

competitive

advantage

of

our

owns.

The

machines

from

our

company

carry

good

quality

and

effective

after-sales

service,

upon

the

market,

customers

from

more

than

45

countries,

we

provide

complete

solution

for

your

plastic

industry

business,

as

well

as

all

sorts

of

technical

support

&

after-sale

services!

DAWSON

will

be

your

reliable

friend

in

China,

and

we

will

always

do

our

best

to

give

you

max

support!

Customer

Photos

We

committed

to

providing

customers

with

plastic

machinery

&

equipment

production

lines

beyond

expectations.

Customer

satisfaction

is

our

eternal

pursuit...

|

|

Q:

Can

we

visit

your

factory?

Sure.

We

located

in

Zhangjiagang

city

which

is

very

near

Shanghai.

For

overseas

customers,

you

can

fly

to

Shanghai

Pudong

International

Airport.

We

can

pick

you

up

in

the

Airport.

(or

Hongqiao

International

Airport.

)

We

also

provide

visit

online

by

video.

Q:

How

can

we

get

the

exact

price

of

plastic

machine?

Contact

us

with

the

products

size,

shape,

annual

quantity

and

photo

if

possible.

We

can

recommend

our

machine

models

with

quotation.

Q:

Do

you

provide

any

spare

parts

with

machine?

Yes,

we

offer

all

necessary

spare

parts

before

shipment.(contact

us

for

packing

list

)

Q:

How

about

your

after-sale

service

?

We

offer

manual

instruction

and

engineer

training

before

loading,after

shipment

we

provide

24

HRS

online

support,

video

technical

support

or

field

installation

assist.

Q:

What

is

the

lead

time?

For

customized

machine,

it

takes

about

45-50

days

after

deposit.

For

stock

machine,

fast

shipment.

(

The

actual

production

cycle

will

vary

according

to

the

degree

of

customization.)

Q:

What

is

the

warranty

period

for

your

machine

?

12

months

warranty

for

components

and

technical

support

.

Q:

Do

you

provide

custom

machines?

Most

of

our

machines

are

customized.

Our

goal

is

efficiency

and

stable

performance.

We

design

the

machines

according

to

customers

products

to

meet

customer'

needs.

Q:

How

can

we

install

the

machine

when

it

arrives?

We

can

send

experienced

technicians

to

customer's

country

for

guiding

the

installation

and

commission

the

machine,

also

train

the

customer's

employees.

Q:

What's

DAWSON's

advantage?

DAWSON

provide

customers

with

turnkey

projects.

Including

plant

design,

plastic

machine

and

mold

installation,

debugging,

also

we

can

source

the

auxiliary

equipment

for

customers.

We

can

ship

the

full

set

of

machines

after

testing

in

our

factory.

It

will

save

a

lot

of

cost

and

time.

DAWSON

will

be

your

reliable

friend

in

China,

and

we

will

always

do

our

best

to

give

you

max

support!

|