| Price | USD 20000-80000 /piece |

| MOQ | 1 piece |

| Delivery Time | 45-65 days |

| Brand | Dawson |

| Place of Origin | CHINA |

| Certification | CE |

| Model Number | IBM65D |

| Packaging Details | wooden |

| Payment Terms | L/C, T/T |

| Supply Ability | 20 pieces per month |

| Mould Material | S136, P20, 4Cr13 | Place of Origin | CHINA |

| Heating Capacity | 10kw | Clamping Force of Blowing | 89kn |

| Warranty | 1 Year | Clamping Force of Injection | 650kn |

| Packaging Details | wooden | Water Flowage | 4m3/H |

| Model Number | IBM65D | Supply Ability | 20 pieces per month |

| Certification | CE | Sutiable Material | HDPE, PP, PVC, PS, PETG, LDPE |

| Brand Name | Dawson | Payment Terms | L/C, T/T |

| Station | Three in One | Price | USD 20000-80000 /piece |

| Delivery Time | 45-65 days | Max. Product Volume | 1L |

| Minimum Order Quantity | 1 piece | Blow moulding type | Injection Blow Moulding |

| Application | Eye Dropper, Medicine Bottle, Chemical Bottle | More Application | Milk & Yogurt Bottle |

| Automatic | Yes,Semi-automatic |

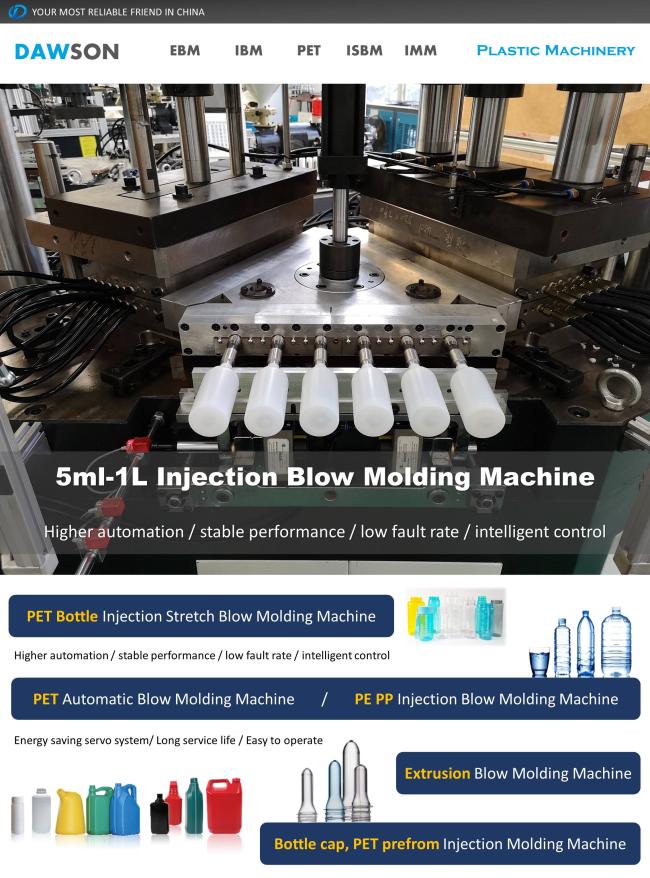

It is suitable for processing large quantities of 5ml to 1L small plastic refined containers and wide mouth containers, such as cosmetics, daily necessities, medicine and food packaging bottles.

INJECTION BLOW MOLDING MACHINE IBM35D PARAMETERS

Bottle is a container that can hold liquid or solid, which can be seen everywhere in our life, including medicine bottle, cosmetics bottle and beverage bottle. Due to the rapid development of the petroleum industry, human beings invented high molecular polymer, which is commonly known as plastics. Since then, our bottle materials have changed from single glass or ceramics to various kinds of plastics. Drawing lessons from the long history of glass container blowing process, the extrusion or injection molding plastic mold in relativistic state is placed in the blowing mold, and the mold is inflated by a certain pressure of compressed air to make it close to the cavity wall. After cooling and setting, the mold is demolished to obtain the plastic hollow products with the same shape as the cavity. This is the hollow blow molding process we are familiar with.

In

the

production

of

the

same

product,

injection

blowing

and

extrusion

blowing

have

inherent

advantages,

such

as

no

flash,

no

waste,

accurate

size,

high

production

efficiency

of

three-step

method,

three

working

positions

working

at

the

same

time,

no

need

to

wait

in

neutral

position;

With

the

conveyor

belt,

the

testing

equipment

can

directly

enter

the

packaging

station,

with

a

high

degree

of

automation.

Therefore,

a

conclusion

can

be

drawn:

in

the

range

of

packaging

bottles,

the

injection

blowing

process

can

improve

the

production

efficiency

and

reduce

the

production

cost.

Dawson injection blow molding machine is equipped with professional injection system and precision control system, which can meet the requirements of high-speed opening and closing mold, high clamping force and uniform distribution of clamping force at each position of the mold. The three position rotary lifting system can rotate 120 ° to make the three positions of injection molding, blow molding and demoulding run continuously and smoothly. At the same time, due to the use of hydraulic drive linkage mechanism, the positioning of the machine is more accurate, the maintenance cost is lower, and it is more rapid and stable. The demoulding station cooperates with the conveyor belt to realize automatic demoulding, automatic counting and automatic packaging. The whole process avoids manual contact, so that the products produced by the machine can meet the stringent requirements in the field of medicine and healthy.

Our

Professional

Injection

Blow

Molding

Machine

Workshop...

DAWSON MACHINERY & MOULD GROUP

Saudi

Arabia,

Colombia,

Panama,

South

Africa

...

DAWSON MACHINE & MOULD GROUP

we committed to providing customers with plastic machinery & equipment production lines beyond expectations.

Q:

Can

we

visit

your

factory?

Sure.

We

located

in

Zhangjiagang

city

which

is

very

near

Shanghai.

For

overseas

customers,

you

can

fly

to

Shanghai

Pudong

International

Airport.

We

can

pick

you

up

in

the

Airport.

(or

Hongqiao

International

Airport.

)

We

also

provide

visit

online

by

video.

Q:

How

can

we

get

the

exact

price

of

plastic

machine?

Contact

us

with

the

products

size,

shape,

annual

quantity

and

photo

if

possible.

We

can

recommend

our

machine

models

with

quotation.

Q:

Do

you

provide

any

spare

parts

with

machine?

Yes,

we

offer

all

necessary

spare

parts

before

shipment.(contact

us

for

packing

list

)

Q:

How

about

your

after-sale

service

?

We

offer

manual

instruction

and

engineer

training

before

loading,after

shipment

we

provide

24

HRS

online

support,

video

technical

support

or

field

installation

assist.

Q:

What

is

the

lead

time?

For

customized

machine,

it

takes

about

45-50

days

after

deposit.

For

stock

machine,

fast

shipment.

(

The

actual

production

cycle

will

vary

according

to

the

degree

of

customization.)

Q:

What

is

the

warranty

period

for

your

machine

?

12

months

warranty

for

components

and

technical

support

.

Q:

Do

you

provide

custom

machines?

Most

of

our

machines

are

customized.

Our

goal

is

efficiency

and

stable

performance.

We

design

the

machines

according

to

customers

products

to

meet

customer'

needs.

Q:

How

can

we

install

the

machine

when

it

arrives?

We

can

send

experienced

technicians

to

customer's

country

for

guiding

the

installation

and

commission

the

machine,

also

train

the

customer's

employees.

Q:

What's

DAWSON's

advantage?

DAWSON

provide

customers

with

turnkey

projects.

Including

plant

design,

plastic

machine

and

mold

installation,

debugging,

also

we

can

source

the

auxiliary

equipment

for

customers.

We

can

ship

the

full

set

of

machines

after

testing

in

our

factory.

It

will

save

a

lot

of

cost

and

time.

DAWSON

will

be

your

reliable

friend

in

China,

and

we

will

always

do

our

best

to

give

you

max

support!