| Price | USD 20,000 ~ 70,000 / set |

| MOQ | 1 set |

| Delivery Time | 5-8 weeks |

| Brand | DAWSON |

| Place of Origin | CHINA |

| Certification | CE |

| Model Number | YCQ |

| Packaging Details | Standard Export Packing |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Supply Ability | 10-20 sets / month |

| Theory output | 300~12000 pcs/h | PLC | Mitsubishi |

| Packaging Details | Standard Export Packing | Blowing Cylinder | Festo |

| Supply Ability | 10-20 sets / month | Cavity | 2, 4, 6, 8, 10, 12 |

| Minimum Order Quantity | 1 set | Revolve Cylinder | SMC |

| Place of Origin | CHINA | Warranty | 12 Months |

| After-sales service provided | Engineers available to service machinery overseas,commissioning and training,Video technical support | Material | PET |

| Touch Screen | Hitech | Controlled by | PLC |

| Model Number | YCQ | Certification | CE |

| Brand Name | DAWSON | Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Switch | Omron | Price | USD 20,000 ~ 70,000 / set |

| Delivery Time | 5-8 weeks | Volume | 0~20 L |

| Moulding Closing and Opening Cylinder | Festo | Value | Festo |

| Application | Beverage Bottle, Oil Bottle | Automatic | Fully Automatic |

DAWSON

MACHINERY

&

MOULD

GROUP

Our

customers

are

all

around

the

world.

Vietnam,

Australia,

Indonesia,

Malaysia,

Thailand,

Sri

Lanka,

Kazakhstan,

Russia,

UAE,

Saudi

Arabia,

Malta,

Romania,

Italy,

India,

Syria,

Ethiopia,

Egypt,

Sudan,

Tunisia,

Algeria,

Kenya,

Nigeria,

South

Africa,

Zimbabwe,

Mexico,

Guatemala,

Ecuador,

Colombia,

Venezuela,

Peru....

Water

bottle

PET

blow

molding

machine

!!

HIGH

SPEED

!!

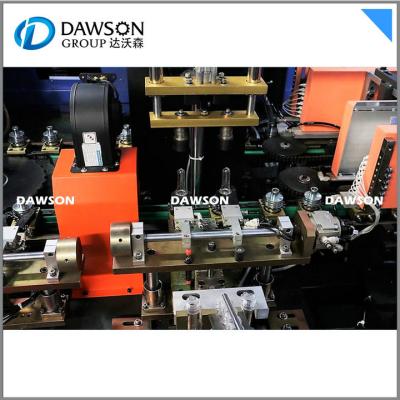

YCQ

Water

bottle

blow

molding

machine

with

2~8

cavities

is

specially

designed

to

produce

water

bottole,

PET

bottle

with

high

heat

resistance

for

hot

filling

package

such

as

juice

and

tea.

It

adopts

multiple

blowing

to

reduce

the

residual

stress,

as

result

shaped

bottle

has

slight

shrinkage

during

hot

filling.

In addition, crystallization varies with different mold design, as a result, the PET bottle produced can stand temperature over 90°C depending on the type of PET material with different crystallization rate. The neck up blowing mode protects the bottle preform from damage during blowing and ensures stable performance. With high strength, good transparency and low production costs, abundant material resource, YCQ plays a big role in hot filling package market.

Technical

Parameter

Automatic

Type

Machine

| Model | Item | YCQ-2 | YCQ-4 | YCQ-6 | YCQ-8 |

| Productivity | Depend on bottle design | 2400-3000PCS/H | 3500-4500PCS/H | 5500-6500PCS/H | 8000-9000PCS/H |

| Product type | Volume | 0.1-2.0L | 0.1-2.0L | 0.1-2.0L | 0.1-2.0L |

| Body diameter | ≤100mm | ≤100mm | ≤100mm | ≤100mm | |

| Height | ≤310mm | ≤310mm | ≤330mm | ≤330mm | |

| Neck diameter | ≤38mm | ≤38mm | ≤38mm | ≤38mm | |

| Mold | Cavity | 2 | 4 | 6 | |

| Mold thickness | 240mm | 240mm | 240mm | 240mm | |

| Mold volume | 260*240*370mm | 510*240*360mm | 640*240*360mm | 640*240*360mm | |

| Main machine power | Electrical source power | 380V/220V 50/60HZ | 380V/220V 50/60HZ | 380V/220V 50/60HZ | 380V/220V 560/60HZ |

| 3Phase | 3Phase | 3Phase | 3Phase | ||

| Rated power | 25kw | 49kw | 73kw | 97kw | |

| Really use power | 6.5kw | 13kw | 25kw | ||

| Air system | HP air compressor | 1.6m³/min3.0Mpa | 3.0m³/min3.0Mpa | 6.0m³/min3.0Mpa | 6.0m³/min3.0Mpa |

| LP air compressor | 1.0m³/min1.0Mpa | 1.6m³/min1.0Mpa | 2.0m³/min1.0Mpa | 23.0m³/min1.0Mpa | |

| Air tank | 0.6m³3.0Mpa | 0.6m³3.0Mpa | 1.0m³3.0Mpa | 1.0m³3.0Mpa | |

| Air dryer | 1.0m³/min3.0Mpa | 2.0m³/min3.0Mpa | 6.0m³/min3.0Mpa | 6.0m³/min3.0Mpa | |

| Cooling water | Water Chiller | 3HP | 3HP | 5HP | 8HP |

| Machine | Size(L*W*H) | 1900*1280*1930mm | 1900*1860*1930mm | 4100*1400*1800mm | 4100*2200*1800mm |

| Weight | 2000kg | 3600kg | 4200kg | 5800kg | |

| Preform unscrambler | Size(L*W*H) | 2000*950*2480mm | 2000*950*2480mm | 2000*950*2480mm | 2000*950*2480mm |

| Weight | 500kg | 500kg | 500kg | 500kg |

Machine

Features

A.

Stable

performance

with

advanced

PLC.

B.

Conveying

preforms

automatically

with

conveyor.

C.

Strong

penetrability

and

good

and

swift

distribution

of

the

heat

by

letting

the

bottles

rotate

by

itself

and

revolute

in

the

rails

simultaneously

in

the

infrared

preheater.

D.

High

adjustability

to

enable

the

preheater

to

preheat

preforms

in

shapes

by

adjusting

the

light

tube

and

the

length

of

the

reflecting

board

in

the

preheating

area,

and

eternal

temperature

in

the

preheater

with

an

automatic

thermostatic

apparatus.

E.

High

safeties

with

security

automatic-locking

apparatus

in

each

mechanical

action,

which

will

make

the

procedures

turn

into

a

state

of

safety

in

case

of

a

breakdown

in

certain

procedure.

F.

No

contamination

and

low

noise

with

the

air

cylinder

to

drive

the

action

instead

of

the

oil

pump.

G.

Satisfaction

with

different

atmospheric

pressure

for

blowing

and

mechanical

action

by

dividing

the

blowing

and

action

into

three

parts

in

the

air

pressure

diagram

of

the

machine.

H.

Strong

clamping

force

with

high

pressure

and

double

crank

links

to

lock

the

mold.

I.

Two

ways

of

operating:

Automatic

and

manual.

J.

Safe,

reliable,

and

unique

design

of

the

position

of

valve

to

make

the

air

pressure

diagram

of

the

machine

easier

to

understand.

K.

Low

cost,

high

efficiency,

easy

operation,

easy

maintenance,

etc,

with

automatic

technological

process.

L.

Contamination

is

avoided

for

the

bottle

body.

M.

Ideal

effect

of

the

chilling

with

the

chilling

system.

N.

Easy

installation

and

starting.

O.

Low

rejection

rate:

Less

than

0.3percent.

Machine Parts

| Blowing Cylinder | Festo | Germany |

| Moulding Closing and Opening Cylinder | Festo | Germany |

| Value | Festo | Germany |

| Revolve Cylinder | SMC | Japan |

| PLC | Mitsubishi | Japan |

| Touch Screen | Hitech | Taiwan |

| Switch | Omron | Japan |

Our

service

Installation

service

When

you

finish

the

Preparation

conditions,our

fast

and

professional

aftersales

service

engineer

team

will

go

to

your

factory

to

install

the

machine,give

you

the

operating

manual,and

train

your

employee

until

they

can

operate

the

machine

well.

The

sample

service

1.We

can

send

you

the

video

of

the

running

machine.

2.You

are

welcome

to

come

to

visit

our

factory,and

see

the

machine

running.

Customized

service

1.We

can

design

the

machines

according

your

requirements(materil,power,filling

type,the

kinds

of

the

bottles,and

so

on),at

the

same

time

we

will

give

you

our

professional

suggestion,as

you

know,we

have

been

in

this

industry

for

many

years.

After-sales

service

1.We

will

delivery

the

machine

and

provide

the

bill

of

load

on

time

to

make

sure

you

can

get

the

machine

quickly

2.When

you

finish

the

Preparation

conditions,our

fast

and

professional

aftersales

service

engineer

team

will

go

to

your

factory

to

install

the

machine,give

you

the

operating

manual,and

train

your

employee

until

they

can

operate

the

machine

well.

3.

We

often

ask

feedback

and

offer

help

to

our

customer

whose

machine

have

been

used

in

their

factory

for

some

time.

4.We

provide

one

year

warranty

5.Well-trained

&

experienced

staff

are

to

answer

all

your

inquiries

in

English

and

Chinese

6

.24

hours

for

engineer

response

(all

services

part

5days

in

customer

hand

by

Intl'

courier).

7

.12

Months

guarantee

and

life-long

technical

support.

8.Your

business

relationship

with

us

will

be

confidential

to

any

third

party.

9.

Good

after-sale

service

offered,

please

get

back

to

us

if

you

got

any

questions.

Quality

Control

We

have

the

single

quality

department,that

make

sure

the

material

of

the

raw

materials

is

good,and

ensure

the

machine

running

smoothly.

If

you

want

to

know

more

information

about

the

product,You

can

send

an

inquiry,

we

will

solve

any

of

your

problems

and

send

you

running

vedio.