Production

Description

Dawson

has

accumulated

over

20

years

of

experience

in

mechanical

andmold

production.Applicable

to

all

kinds

of

PET

bottles

which

used

for

oil,soft

drinks.mineral

waterwine,

medicine,

cosmetics,

etc.

Semi

-

Automatic

PET

Can

Blow

Molding

Machine:

Unleashing

Packaging

Potential

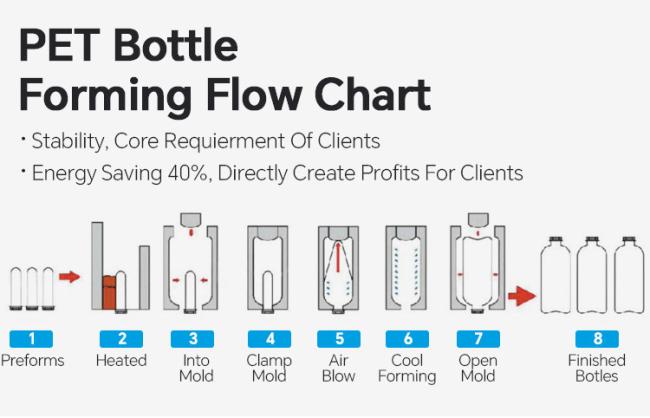

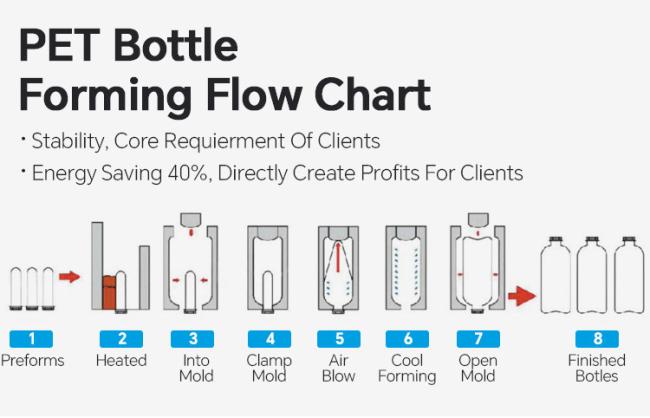

In

the

fast

-

paced

realm

of

packaging

production,

the

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

has

emerged

as

a

game

-

changer.

This

sophisticated

machinery

is

engineered

to

convert

pre

-

forms

into

an

array

of

PET

cans,

catering

to

diverse

industry

needs

with

remarkable

efficiency

and

precision.

Advanced

Technological

Features

Precise

Temperature

Control

At

the

heart

of

the

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

lies

an

advanced

temperature

control

system.

Precise

heating

is

crucial

during

the

pre

-

form

transformation

process.

The

machine

employs

state

-

of

-

the

-

art

heating

elements

that

can

accurately

adjust

and

maintain

the

optimal

temperature

for

the

PET

material.

This

not

only

ensures

consistent

quality

in

the

final

cans

but

also

reduces

the

likelihood

of

material

degradation.

For

example,

different

grades

of

PET

require

specific

temperature

ranges

for

proper

molding.

The

machine's

temperature

control

system

can

be

fine

-

tuned

to

meet

these

exact

requirements,

resulting

in

cans

with

uniform

wall

thickness

and

excellent

mechanical

properties.

Intelligent

Air

Blowing

System

The

air

blowing

mechanism

in

this

machine

is

another

area

of

innovation.

It

is

equipped

with

an

intelligent

air

pressure

regulator

that

can

precisely

control

the

amount

and

force

of

air

injected

into

the

pre

-

form.

This

enables

the

creation

of

cans

with

intricate

shapes

and

varying

sizes.

Whether

it's

a

slender,

tall

can

for

energy

shots

or

a

wide

-

bodied

can

for

bulk

products,

the

air

blowing

system

can

adapt

to

the

mold's

specifications.

Moreover,

the

ability

to

regulate

air

pressure

in

real

-

time

helps

in

preventing

defects

such

as

uneven

inflation

or

thin

spots

in

the

can

walls.

Adaptability

for

Different

Production

Scales

Small

-

Scale

Production

For

small

-

scale

businesses

or

start

-

ups

in

the

packaging

industry,

the

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

offers

an

ideal

solution.

Its

semi

-

automatic

operation

allows

for

greater

flexibility

in

production

runs.

Small

batches

can

be

produced

with

ease,

as

the

machine

can

be

quickly

set

up

and

adjusted

for

different

can

designs.

This

is

particularly

beneficial

for

companies

that

are

testing

new

product

concepts

or

targeting

niche

markets.

The

lower

initial

investment

compared

to

fully

-

automatic

machines

also

makes

it

an

attractive

option

for

those

with

limited

capital.

Medium

-

Scale

Production

Medium

-

scale

manufacturers

can

significantly

enhance

their

productivity

with

the

Semi

-

Automatic

PET

Can

Blow

Molding

Machine.

With

a

relatively

high

production

capacity,

it

can

handle

a

substantial

volume

of

pre

-

forms

in

a

given

time

frame.

The

machine's

modular

design

allows

for

easy

expansion

or

modification.

For

instance,

additional

molds

can

be

added

to

increase

the

variety

of

can

sizes

and

shapes

produced.

This

scalability

enables

medium

-

scale

enterprises

to

meet

growing

market

demands

without

having

to

invest

in

a

completely

new

production

line.

Quality

Assurance

and

Compliance

Stringent

Quality

Checks

The

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

is

designed

with

multiple

quality

control

points

built

into

its

operation.

After

each

can

is

formed,

it

undergoes

a

series

of

checks,

including

visual

inspection

for

surface

defects,

dimensional

accuracy

measurement,

and

wall

thickness

testing.

These

quality

checks

are

automated

to

a

large

extent,

ensuring

consistent

and

reliable

results.

This

high

-

level

of

quality

assurance

is

essential

for

industries

such

as

food

and

beverage,

where

product

safety

and

integrity

are

of

utmost

importance.

Compliance

with

Industry

Standards

Manufacturers

using

this

machine

can

rest

assured

that

their

PET

cans

will

meet

international

industry

standards.

The

machine

is

engineered

to

comply

with

regulations

related

to

food

contact

materials,

ensuring

that

the

cans

are

safe

for

packaging

consumable

products.

Additionally,

it

adheres

to

environmental

standards,

as

PET

is

a

recyclable

material.

The

production

process

itself

is

optimized

to

minimize

waste

and

energy

consumption,

aligning

with

the

growing

global

focus

on

sustainable

manufacturing.

Cost

-

Efficiency

and

Return

on

Investment

Low

Operating

Costs

The

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

is

known

for

its

cost

-

efficient

operation.

Its

energy

-

saving

design

reduces

electricity

consumption,

which

is

a

significant

cost

factor

in

long

-

term

production.

The

machine

also

has

relatively

low

maintenance

requirements,

thanks

to

its

durable

construction

and

high

-

quality

components.

Spare

parts

are

readily

available,

and

maintenance

tasks

can

be

carried

out

quickly,

minimizing

downtime.

This

combination

of

low

energy

and

maintenance

costs

results

in

substantial

savings

over

the

machine's

lifespan.

High

Return

on

Investment

Despite

its

relatively

affordable

price

tag,

the

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

offers

a

high

return

on

investment.

Its

ability

to

produce

high

-

quality

PET

cans

efficiently

means

that

manufacturers

can

increase

their

output

and

revenue.

The

versatility

of

the

machine,

allowing

for

the

production

of

a

wide

range

of

can

sizes

and

shapes,

also

opens

up

new

market

opportunities.

By

meeting

diverse

customer

demands,

businesses

can

expand

their

customer

base

and

ultimately

achieve

a

higher

return

on

their

investment

in

the

machine.

In

summary,

the

Semi

-

Automatic

PET

Can

Blow

Molding

Machine

is

a

powerful

tool

in

the

packaging

industry.

Its

advanced

technological

features,

adaptability

to

different

production

scales,

commitment

to

quality

assurance

and

compliance,

and

excellent

cost

-

efficiency

make

it

a

top

choice

for

manufacturers

looking

to

enhance

their

packaging

production

capabilities.

Whether

you

are

a

small

-

scale

entrepreneur

or

a

medium

-

scale

industrialist,

this

machine

has

the

potential

to

revolutionize

your

packaging

operations

and

drive

your

business

forward.

|

TechnicalParameters

|

ZP-2L-2

|

ZP-2L-4

|

|

Molding

|

Clamping

Foree

|

14000KG

|

28000KG

|

|

|

Clamping

Stroke

|

155mm

|

190mm

|

|

|

Stretehing

Stroke

|

370mm

|

370mm

|

|

|

Cavity

Spacing

|

90-130mm

|

100-110mm

|

|

|

Number

of

Cavity

|

2Cavities

|

4Cavities

|

|

|

Carriage

Unit

|

72pCs

|

96pcs

|

|

|

Theoretieal

Output

|

800-1000bph

|

1600-2000bph

|

|

Electrical

System

|

Heating

Power

|

28-0.5KW

|

32-0.8KW

|

|

|

Number

of

lamp

Layers

|

7

layers

|

8layers

|

|

Air

System

|

Operating

Pressure

|

7-9KG

|

7-9KG

|

|

|

Low

Pressure

Air

Consumption

|

0.6M?/MIN

|

0.8M?/MIN

|

|

|

Blowing

Pressure

|

20-30BAR

|

20-30BAR

|

|

|

High

Pressure

Air

Consumption

|

1.2M/MIN

|

2.4M/MIN

|

|

Chiler

|

Operating

Pressure

|

2-4BAR

|

2-4BAR

|

|

|

Temperature

Range

|

10-12°C

|

10-12°C

|

|

|

Consumption

|

1

5MP/MIN

|

1

5MP/MIN

|

|

|

Power

|

3P

|

3P

|

1.

Adopt

PLC

control

system,

easy

to

operate

2.Upgrade

power

efficiency.

3.

Simplified

operation

by

HMl

control

panel.

4.

Modular

design

facilitates

maintenance.

5.

Energy

saving

.high

capacity

Details

Our

machine

Customer

References