Falling

Film

Wastewater

MVR

Evaporator

System

For

Crystallization

&

Chemical

Desalination

Engineer-to-order

falling

film

MVR

(Mechanical

Vapor

Recompression)

evaporator

for

wastewater

concentration,

chemical

desalination,

and

salt

crystallization.

Thin-film

vacuum

boiling

protects

heat-sensitive

streams

while

MVR

recycles

latent

heat,

delivering

low

OPEX,

deep

TDS

reduction,

and

continuous,

stable

operation

for

ZLD

schemes.

Key

Benefits

-

High

energy

efficiency:

Electric-driven

vapor

recompression

minimizes

fresh

steam

after

start-up.

-

Desalination

&

crystallization:

Drives

brine

to

supersaturation

for

salt

recovery

and

reduced

discharge.

-

Low

ΔT,

high

quality:

Falling-film

duty

preserves

organics

and

limits

thermal

degradation/foaming.

-

Scaling

mitigation:

Optimized

ΔT/LMTD

and

film

distributors,

antiscalant

dosing,

CIP-ready

design.

-

Automated

uptime:

PLC/HMI

recipes,

alarms,

historian,

and

remote

diagnostics

for

24/7

operation.

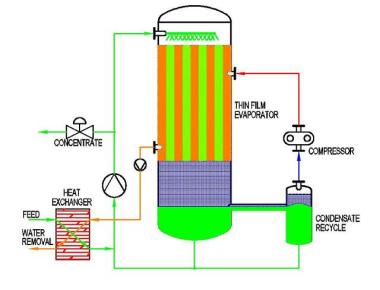

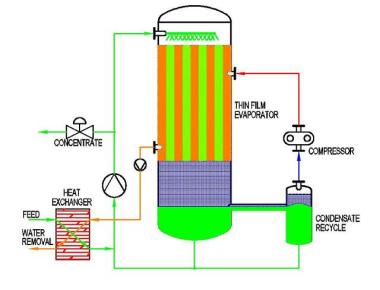

Process

&

Thermal

Economy

Secondary

vapor

is

mechanically

compressed

to

elevate

saturation

temperature

and

reused

as

the

heating

medium.

Even

film

distribution

over

vertical

exchangers

maintains

high

heat-transfer

coefficients;

controlled

residence

time

and

pressure/ΔT

setpoints

enable

predictable

desalination

and

crystallization

with

low

specific

energy.

Materials

&

Cleanability

Wetted

parts

in

SS316L/duplex

(Ti/Hastelloy

optional).

Drainable

layouts,

large

access

for

inspection,

validated

CIP,

and

elastomer/material

selections

per

chemistry

(chlorides,

solvents,

acids/alkalis).

Process

Overview

--

Wastewater

Desalination

to

Crystals

-

Feed

conditioning:

screening/filtration,

softening

or

pH

trim,

antiscalant

to

control

Ca/Mg/Si

scaling.

-

MVR

falling

film

(vacuum):

VFD

compressor

controls

ΔT;

shell

vacuum

defines

boiling

point.

-

Crystallization:

seeded

growth

(DTB/OSLO/FC)

for

targeted

PSD

and

purity;

mother

liquor

recycle.

-

Condensate

polishing:

filters/RO/AC

to

meet

reuse

or

discharge

limits

(conductivity/TOC

guard).

-

Solids

handling/ZLD:

centrifuge

->

dryer

->

regulated

disposal

or

resource

recovery.

Key

Components

-

Falling-film

evaporator

body

with

film

distributors

and

vapor-liquid

separator

-

MVR

mechanical

vapor

compressor

(turbo/Roots)

with

VFD

for

ΔT/capacity

control

-

Surface

condenser,

vacuum/NCG

handling,

preheaters/heat

recovery

HX

-

Crystallizer,

centrifuge,

dryer;

condensate

polishing

skid

-

PLC/HMI/SCADA;

instruments

(T/P/flow/cond/level);

CIP

and

antiscalant

dosing

Performance

&

Sizing

|

Parameter

|

Typical

Range*

|

|

Operation

|

Continuous,

vacuum

|

|

Electric

use

(MVR)

|

~15-40

kWh

per

ton

of

water

evaporated

|

|

Shell

pressure

|

~6-25

kPa(abs),

duty-dependent

|

|

Desalination

depth

|

Up

to

crystallization/solid

discharge

(feed-dependent)

|

|

Materials

|

SS316L

/

duplex;

Ti/Hastelloy

on

request

|

*Actual

performance

depends

on

feed

salinity/COD,

fouling

tendency,

compression

ratio,

and

crystallizer

design.

FAQ

Can

it

follow

membranes

to

reach

ZLD?

Yes--common

flowsheets

pair

RO/NF

pre-concentration

with

falling-film

MVR

and

a

crystallizer

for

final

solids

discharge.

How

do

you

control

scaling

on

high-TDS

streams?

Through

pretreatment,

optimized

film

ΔT/velocity,

antiscalant

dosing,

and

scheduled

CIP

with

online

fouling

indicators.

What

condensate

quality

is

achievable?

Low

conductivity/TOC

suitable

for

reuse

after

polishing;

quality

guards

ensure

compliance

with

site

limits.

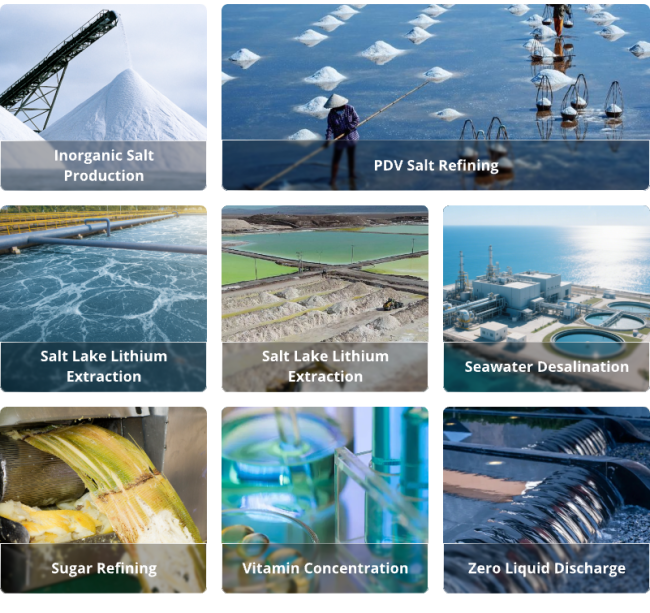

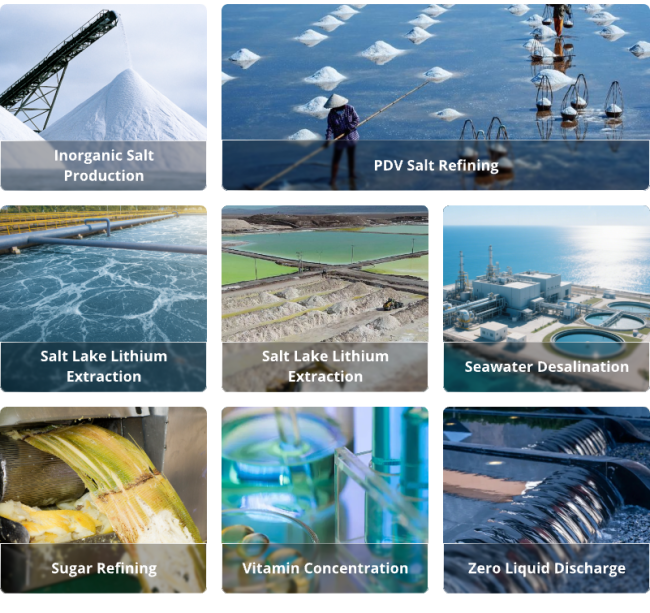

Application