| Price | 100,000USD~2,500,000USD/SET |

| MOQ | 1 set |

| Delivery Time | 3 months |

| Brand | HANPU |

| Place of Origin | Jiangsu,China |

| Certification | ISO9001,CE |

| Model Number | MVR |

| Packaging Details | Bulk with includes fixtures |

| Payment Terms | T/T,L/C,D/A,D/P |

| Supply Ability | 1 set/90days |

| Brand Name | HANPU | Payment Terms | T/T,L/C,D/A,D/P |

| Place of Origin | Jiangsu,China | Price | 100,000USD~2,500,000USD/SET |

| Delivery Time | 3 months | Minimum Order Quantity | 1 set |

| Packaging Details | Bulk with includes fixtures | Model Number | MVR |

| Supply Ability | 1 set/90days | Certification | ISO9001,CE |

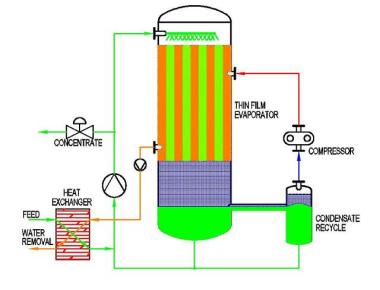

Engineer-to-order single-effect falling film evaporator in SS316L, integrated with MVR (Mechanical Vapor Recompression) and an ethanol crystallizer section for solvent recovery, concentration, and controlled crystallization (API/fine chemicals/bioproducts). Vacuum operation and recompressed vapor duty provide low temperature, high efficiency, and consistent crystal quality.

Secondary vapor is mechanically compressed to elevate saturation temperature and reused as the heating medium. Falling-film operation maintains uniform film temperature and high heat-transfer coefficients, limiting degradation and fouling while stabilizing supersaturation for crystallization downstream.

Wetted parts in SS316L (Duplex/Ti/Hastelloy on request). Solvent-service options: explosion protection (ATEX/NFPA concepts), nitrogen blanketing, solvent-rated seals, LEL monitoring, and conductive gaskets/hoses.

| Parameter | Typical Range* |

|---|---|

| Operation | Continuous, vacuum |

| Electric use (MVR) | ~15-40 kWh per ton of water/solvent evaporated |

| Film ΔT | Low (duty/CR dependent) to protect heat-sensitive actives |

| Crystal PSD (D50) | Tunable via seed load, ΔT, and residence time |

| Materials | SS316L standard; Duplex/Ti/Hastelloy optional |

Can

one

system

both

concentrate

and

crystallize?

Yes--falling-film

MVR

provides

gentle

concentration;

the

downstream

crystallizer

finalizes

PSD

and

purity.

How

is

solvent

safety

addressed?

Options

include

nitrogen

inerting,

LEL/VOC

monitoring,

conductive

components,

and

explosion-protection

design

per

code.

What

about

ethanol

recovery

quality?

Condensate

polishing

(e.g.,

carbon/IX)

delivers

high-purity

ethanol

suitable

for

reuse,

reducing

make-up

solvent

cost.