Energy

Saving

MVR

Evaporator

PLC

Engine

Zero

Liquid

Discharge

Wastewater

Engineer-to-order

MVR

(Mechanical

Vapor

Recompression)

evaporator

for

ZLD

wastewater

treatment.

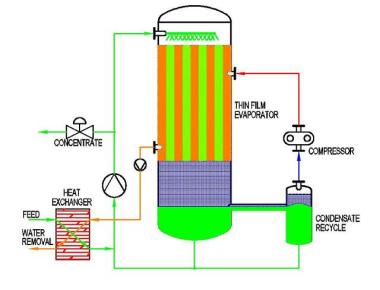

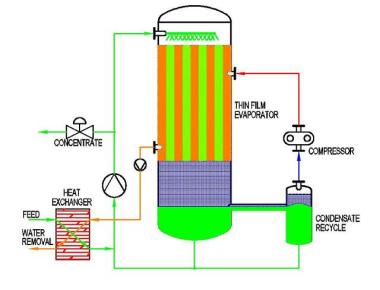

The

system

recycles

latent

heat

via

mechanical

recompression

to

minimize

utilities,

while

a

PLC

control

engine

orchestrates

continuous,

unattended

operation—delivering

low

OPEX,

high

recovery,

and

compliant

discharge

as

solids.

Key

Benefits

-

Energy

saving:

Electric-driven

MVR

slashes

fresh-steam

demand

after

start-up.

-

ZLD-ready:

Deep

concentration

to

crystallizer/centrifuge/dryer

for

zero

liquid

discharge.

-

Smart

automation:

PLC/HMI

with

recipes,

alarms,

historian,

remote

diagnostics,

and

load

following.

-

Stable

operation:

Vacuum

low-ΔT

duty,

optimized

ΔT/LMTD

and

velocity

to

reduce

fouling

and

foaming.

-

Durable

materials:

SS316L/duplex

(Ti/Hastelloy

optional)

for

corrosive

brines

and

chemicals.

Process

&

Thermal

Economy

Secondary

vapor

is

mechanically

compressed

to

elevate

saturation

temperature

and

reused

as

the

heating

medium.

Tight

control

of

pressure,

ΔT,

circulation

rate,

and

residence

time

keeps

coefficients

high

and

specific

energy

low,

producing

condensate

suitable

for

reuse

after

polishing.

PLC

Control

&

Safety

Closed-loop

control

of

level/pressure/temperature/conductivity;

interlocks

for

compressor/VFD,

vacuum

and

NCG

handling,

heater

duty,

and

condensate

quality

guard.

Event/alarm

historian

and

secure

remote

support

enable

24/7

uptime.

Process

Overview

—

ZLD

Wastewater

-

Feed

conditioning:

screening/filtration,

softening

or

pH

trim;

antiscalant

to

limit

Ca/Mg/Si

scale.

-

MVR

evaporation

(vacuum):

falling

film

or

forced

circulation;

compressor

discharge

sets

ΔT/capacity.

-

Condensate

polishing:

filters/RO/AC

to

reuse

or

discharge

spec

(conductivity/TOC

guard).

-

Crystallization

&

solids:

DTB/OSLO

or

FC

crystallizer

→

centrifuge/dryer

→

compliant

solid

disposal

or

recovery.

-

Automation:

PLC

recipes

for

start/stop,

CIP

windows,

and

load-following

with

VFDs.

Key

Components

-

MVR

evaporator

body

(falling

film

/

forced

circulation)

with

vapor-liquid

separator

-

Mechanical

vapor

compressor

(turbo/Roots)

with

VFD

-

Surface

condenser,

vacuum/NCG

skid,

preheaters/heat

recovery

HX

-

PLC/HMI/SCADA;

instrumentation

(T/P/flow/cond/level);

alarm

&

historian

-

CIP

skid;

antiscalant

dosing;

optional

condensate

polishing

filters/RO

Performance

&

Sizing

|

Parameter

|

Typical

Range*

|

|

Operation

|

Continuous,

24/7

(vacuum

duty)

|

|

Electric

use

(MVR)

|

~15-40

kWh

per

ton

of

water

evaporated

|

|

Fresh

steam

demand

|

Very

low

after

start-up

(backup/ancillary

only)

|

|

Turndown

|

50-100%

with

stable

ΔT

and

quality

|

|

Materials

|

SS316L

/

duplex;

Ti/Hastelloy

on

request

|

*Actual

performance

depends

on

feed

salinity/COD,

fouling

tendency,

compression

ratio,

and

heat-exchanger

design.

FAQ

Can

this

integrate

after

membranes

for

ZLD?

Yes.

RO/NF

pre-concentration

upstream

with

MVR

+

crystallizer

downstream

is

a

standard

ZLD

configuration.

How

is

scaling

managed?

Through

pretreatment,

optimized

ΔT/LMTD

and

velocity,

antiscalant

dosing,

and

scheduled

CIP

based

on

fouling

indicators.

What

condensate

quality

is

achievable?

Low

conductivity/TOC;

polishing

enables

reuse

within

the

plant,

reducing

freshwater

intake.

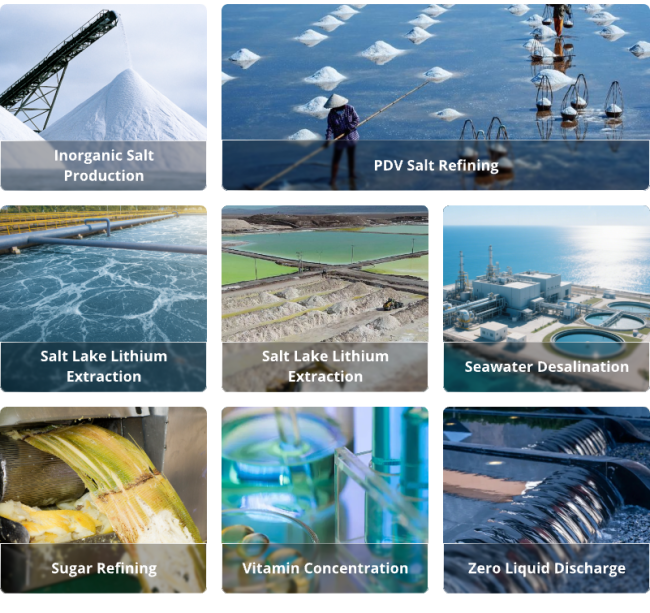

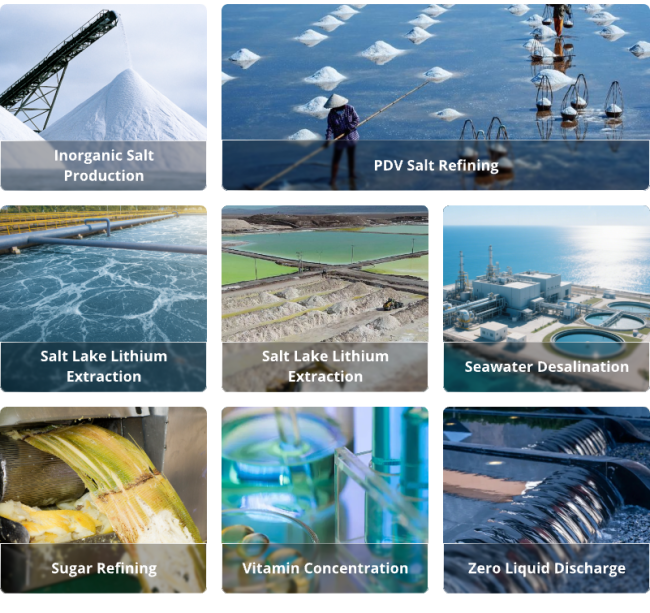

Application