Laser

Welding

Enbossed

Pillow

Plate

MVR

Evaporators

Laser-welded

embossed

pillow

plates

combined

with

MVR

(Mechanical

Vapor

Recompression)

create

a

compact,

energy-saving

evaporator

body

with

wide

channels,

strong

turbulence,

and

hygienic

surfaces.

The

design

supports

gentle

vacuum

evaporation,

low

ΔT

operation,

and

continuous

24/7

duty

for

food,

chemical,

and

environmental

applications.

Key

Benefits

-

Energy

saving:

MVR

recycles

latent

heat;

minimal

fresh

steam

after

start-up.

-

High

heat

transfer:

Embossed

pillows

promote

turbulence

and

coefficients

at

low

ΔT.

-

Fouling

tolerance:

Wide

channels

handle

particulates/viscosity

better

than

narrow-gap

plates.

-

Hygienic

&

serviceable:

SS304/SS316L

surfaces,

drainable

geometry,

CIP-ready,

easy

inspection.

-

Modular

scaling:

Add/remove

plate

banks;

upgrade

path

to

TVR/MVR

hybrids.

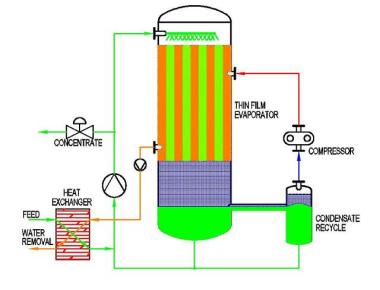

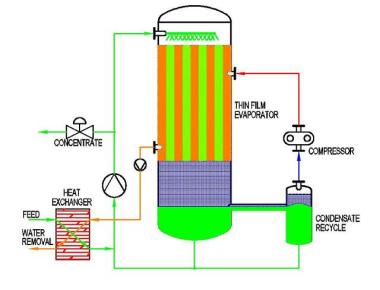

Process

&

Thermal

Economy

Secondary

vapor

is

mechanically

compressed

to

raise

saturation

temperature

and

reused

as

the

heating

medium.

Uniform

film

distribution

over

pillow

plates

under

vacuum

maintains

high

heat-transfer

coefficients

and

protects

heat-sensitive

products,

reducing

specific

energy

consumption.

Materials

&

Construction

Laser-welded

SS304/SS316L

pillow

plates

and

manifolds

(duplex/Ti/Hastelloy

optional).

Orbital-welded

headers,

sanitary

finishes,

slope-to-drain

piping,

and

validated

CIP

documentation

available

for

food-grade

compliance.

Process

Overview

--

Pillow

Plate

MVR

-

Feed

conditioning:

screening/filtration,

pH

trim,

antiscalant

to

limit

Ca/Mg/Si

scaling.

-

Falling-film

duty:

even

wetting

across

embossed

plates;

tight

ΔT/LMTD

control.

-

MVR

compression:

VFD-driven

compressor

sets

discharge

pressure

for

capacity/ΔT

control.

-

Condensate

polishing:

filters/RO/AC

for

reuse

or

compliant

discharge

(conductivity/TOC

guard).

-

Concentrate

routing:

to

crystallizer/centrifuge/dryer

or

recycle

per

ZLD/production

needs.

Key

Components

-

Laser-welded

embossed

pillow

plate

evaporator

stack

with

distributors/collectors

-

MVR

mechanical

vapor

compressor

(turbo/Roots)

with

VFD

-

Vapor-liquid

separator,

surface

condenser,

vacuum/NCG

handling

skid

-

Preheaters/heat-recovery

HX;

PLC/HMI/SCADA

with

historian

-

CIP

skid;

antiscalant

dosing;

T/P/flow/conductivity/level

instrumentation

Performance

&

Sizing

|

Parameter

|

Typical

Range*

|

|

Operation

|

Continuous,

vacuum

duty

|

|

Electric

use

(MVR)

|

~15-40

kWh

per

ton

of

water

evaporated

(duty/CR

dependent)

|

|

Film

ΔT

|

Low

for

quality

preservation;

set

via

compressor

discharge

pressure

|

|

Steam

demand

|

Very

low

after

start-up

(backup/ancillary

only)

|

|

Materials

|

SS304

/

SS316L

standard;

duplex/Ti/Hastelloy

optional

|

*Performance

depends

on

feed

chemistry/viscosity,

fouling

tendency,

compression

ratio,

and

plate

geometry.

FAQ

Why

choose

embossed

pillow

plates?

Embossing

increases

turbulence

and

stiffness,

improving

heat-transfer

coefficients

and

pressure

tolerance

at

low

ΔT.

Can

the

system

be

expanded

later?

Yes--add

plate

banks

or

integrate

TVR/MVR

hybrid

modules

to

increase

capacity

and

reduce

specific

energy

use.

Which

stainless

grade

should

we

pick?

SS316L

is

preferred

for

chlorides/corrosives;

SS304

suits

benign

duties.

Duplex/Ti/Hastelloy

available

per

corrosion

study.

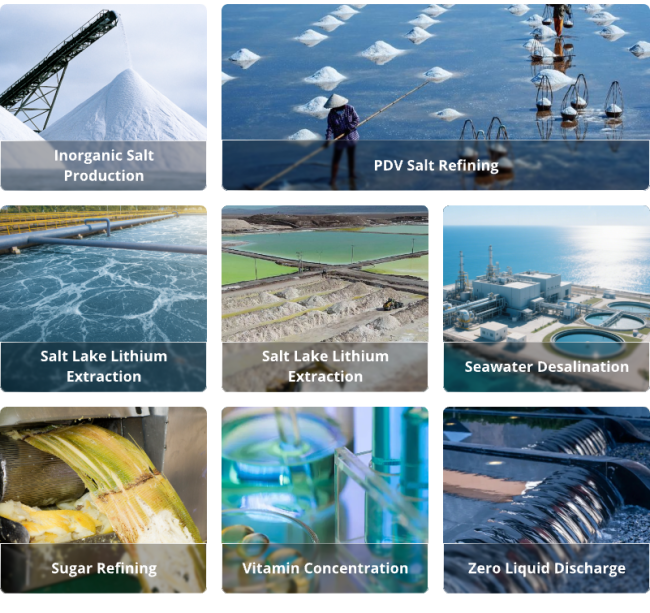

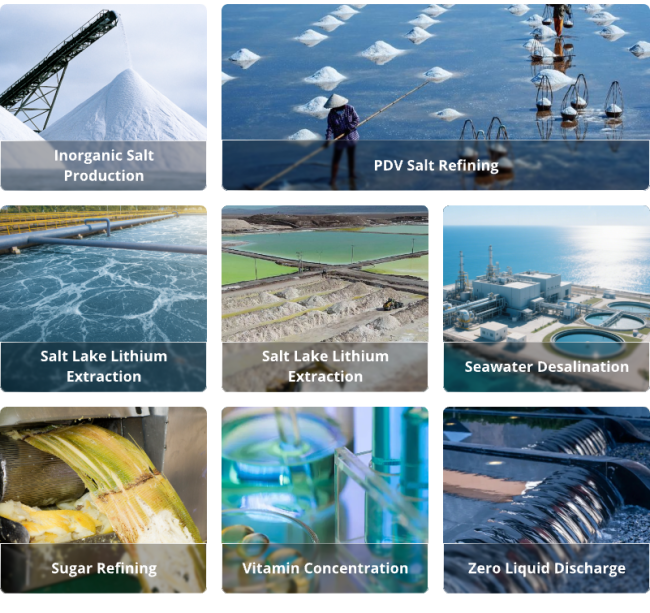

Application