| Price | 300,000USD~2,500,000USD/SET |

| MOQ | 1 set |

| Delivery Time | 90 days |

| Brand | HANPU |

| Place of Origin | Jiangsu,China |

| Certification | CE,ISO9001 |

| Model Number | MVR |

| Packaging Details | Bulk with strong strap |

| Payment Terms | T/T,L/C,D/A,D/P,Western Union |

| Supply Ability | 1 set/month |

| Brand Name | HANPU | Payment Terms | T/T,L/C,D/A,D/P,Western Union |

| Place of Origin | Jiangsu,China | Price | 300,000USD~2,500,000USD/SET |

| Delivery Time | 90 days | Minimum Order Quantity | 1 set |

| Packaging Details | Bulk with strong strap | Model Number | MVR |

| Supply Ability | 1 set/month | Certification | CE,ISO9001 |

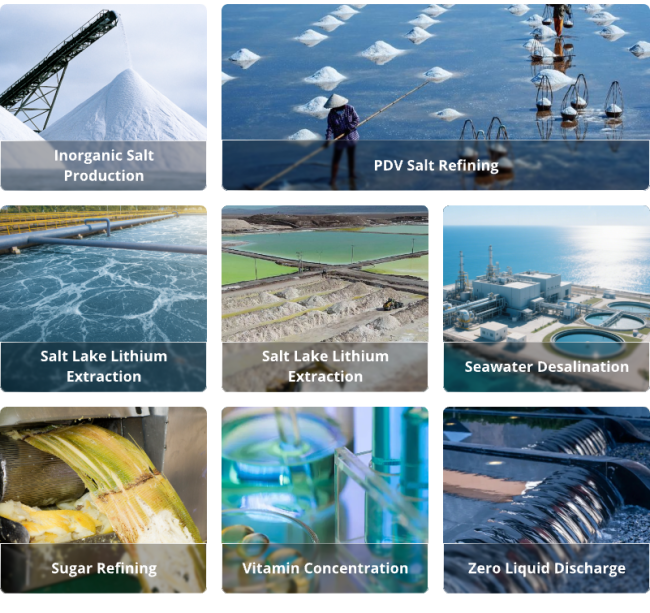

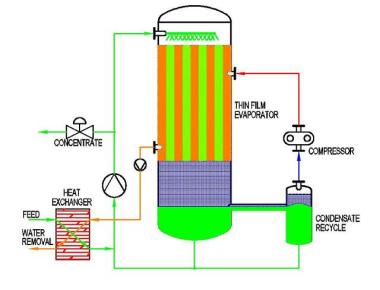

An integrated MVR evaporator plant engineered for energy-efficient evaporation, concentration, and crystallization across chemical, food, and environmental applications. By mechanically recompressing secondary vapor and reusing its latent heat, the plant delivers low OPEX, high recovery, and stable 24/7 operation.

Secondary vapor is mechanically compressed to raise saturation temperature and reused as the heating medium. Optimized Δ T/LMTD, circulation velocity, and residence time maintain high heat-transfer coefficients and consistent condensate quality.

| Parameter | Typical Range* |

|---|---|

| Operation | Continuous, 24/7 (vacuum duty) |

| Electric use (MVR) | ~15-40 kWh per ton of water evaporated |

| Fresh steam demand | Very low after start-up (backup/ancillary only) |

| Turndown | 50-100% with stable ΔT and quality |

| Materials | SS316L / duplex; Ti/Hastelloy on request |

Can

the

plant

integrate

with

existing

membranes?

Yes.

RO/NF

pre-concentration

commonly

precedes

MVR

to

lower

energy

per

unit

water

removed.

How

is

scaling

managed?

Optimized

ΔT/LMTD

and

velocity,

antiscalant

dosing,

material

selection,

and

scheduled

CIP

with

fouling

indicators.

What

condensate

quality

is

achievable?

Low

conductivity/TOC

suitable

for

reuse

after

polishing;

quality

guards

ensure

consistent

compliance.