| Price | USD18,000-USD65,000 |

| MOQ | 1sets |

| Delivery Time | 45-60working days |

| Brand | Hanpu |

| Place of Origin | China |

| Certification | CE ISO |

| Model Number | 3*2m |

| Packaging Details | standard exported wooden case |

| Supply Ability | 50-200sets per months |

| Condition | New | After sale service | Provided |

| Place of Origin | China | Tape | Evaporator |

| Size | 3*2m | Packaging Details | standard exported wooden case |

| Material | SS | Plate thickness | 1-3mm |

| Model Number | 3*2m | Supply Ability | 50-200sets per months |

| Certification | CE ISO | Name | Plate Heat Exchanger Machinery from China |

| Brand Name | Hanpu | Brand | Hanpu |

| Price | USD18,000-USD65,000 | Delivery Time | 45-60working days |

| Minimum Order Quantity | 1sets |

3*2m Stainless Steel Industrial Plate Heat Exchanger Machinery from China

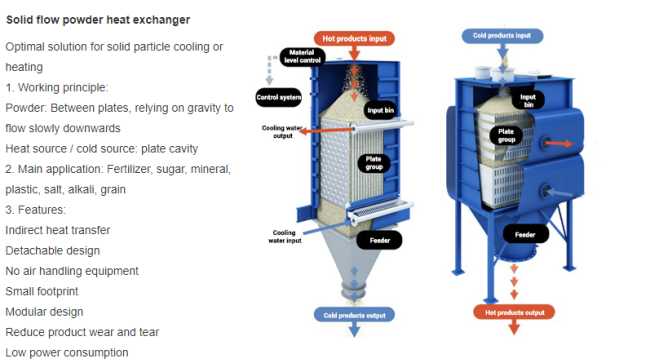

Techology

Two sheets of steel are overlapped and welded by laser. Laser ring welding is used in the middle of the sheet and two laser welding seals are used around the edge.Injecting high-pressure liquid between plates makes the plates expand and deform under pressure, forming a hollow plate heat exchanger with uneven surface.

Pillow plate heat exchanger is a kind of plate heat exchanger assembled by inflated pillow plates, the material of pillow plate can be SS304, SS316, SS316L, DSS, TA2..etc, the sharp, plate thickness, working pressure can be customized to meet your exact requests.

Plate type

Double-sided drum pressure, generally used as immersion heat exchange element.

Feature

1. Suitable for various media: steam, water, oil, etc.

2. Fully welded, no gasket design, no leakage, high working pressure, high working temperature,

3. Special sharp, working pressure, size can be customized

4. Wide flow channel design, the medium can efficiently transfer heat through the flow channel

5. The advantage of double embossed pillow plate is turbulence, improve the heat transfer efficiency than traditional jacket

6. Easy to install in the outer wall of the storage tank and equipment

7. Modular design, compact equipment, small footprint, easy installation, cleaning and maintenance

8. It can meet the requirements of pharmaceutical and food-grade environmental use condition

Specification

| Name | Pillow plate heat exchanger |

| Size | 6*2*2m |

| Thickness | 1.0mm |

| Material | SS304 |

| Embossed | Both sides embossed |

| Working pressure | 120psi |

| Temperature | 180 ℃ |

| Usage | Evaporation in black liquor field |

| Application |

Black liquor, Juice, Milk, Vacuum salt production line, Beer fermentation |

Types

Certificate

Our service:

1.12

months

guarantee

period

from

machine

arriving

date.

2.

Abundant

spare

parts

in

stock

are

available

to

provide.

3.

Our

technicians

could

be

dispatched

for

overseas

service.

4.

7*24

hours

technical

consultation.

5.

Your

workers

could

get

trained

both

in

our

factory

and

yours.

6.

Routine

tracing

till

the

machine

work

properly

will

be

done

timely.

7.

We

will

remind

you

to

do

the

normal

maintenance.

8.

Your

suggestions

or

any

comments

&

reflection

would

be

treated

in

priority.

9.

Marketing

team

will

visit

you

during

our

visit

in

your

country

if

you

require

About us

Jiangsu

Hanpu

Mechanical

Technology

Co.,

Ltd.

is

a

company

mainly

produce

pillow

plate

and

its

related

products,The

company's

production

base

is

located

in

the

Huangqiao

Industrial

Zone

of

Taixing,

covering

an

area

of

300

acres.

The

companies

involved

are

in

the

industry

of

new

material,

new

energy,

medicine,

chemical,

environmental

protection,

food,

and

beverage,

etc.

Jiangsu

Hanpu

is

an

internationally

engineering

company

that

integrates

technical

consulting,

design,

procurement,

construction,

installation

and

driving

into

one,

providing

engineering

EPC

general

contract,

project

management,

engineering

supervision

and

other

services.

The

company

is

Committed

to

be

the

first

and

world-renowned

technology

and

technology

engineering

company

in

Asia,

providing

cutting-edge

technology

and

one-stop

solutions

for

the

world's

industries.

Tag: Pillow plate heat exchanger for sugar, Pillow plate heat exchanger for vacuum salt production line, Pillow plate heat exchanger for beer project