| Price | 160000 |

| MOQ | 1set |

| Delivery Time | 90days-150days |

| Brand | Hanpu |

| Place of Origin | China |

| Certification | ce,iso |

| Packaging Details | Packing in wooden case |

| Payment Terms | L/C,D/A,D/P,T/T |

| Supply Ability | 3sets/per month |

| Brand Name | Hanpu | Payment Terms | L/C,D/A,D/P,T/T |

| Place of Origin | China | Price | 160000 |

| Delivery Time | 90days-150days | Minimum Order Quantity | 1set |

| Packaging Details | Packing in wooden case | Supply Ability | 3sets/per month |

| Certification | ce,iso |

Reuse latent heat via mechanical vapor recompression to cut utility demand, stabilize quality, and lift evaporation throughput.

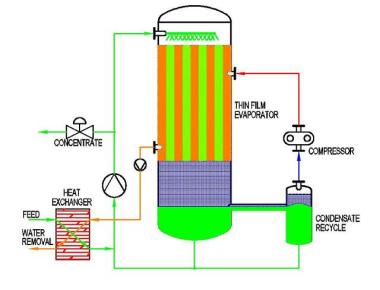

In evaporation, energy and usable capacity often trade off. By compressing secondary vapor and sending it back to the heating side, an MVR system lets the same heat do more work, balancing energy use, footprint, and scalability.

Feed enters the evaporator and boils. The generated secondary vapor is compressed (centrifugal / high-speed turbo / Roots) to a higher pressure and temperature, then routed to the shell side as the heating medium. Vapor/liquid separation follows; condensate is recovered while non-condensables are vented under vacuum. Periodic CIP keeps surfaces clean. PLC control holds evaporation rate, vacuum, surge protection, and energy optimization.

Key Components: Evaporator body, vapor compressor, vapor-liquid separator, main heater, preheater, condenser, vacuum system, CIP skid, instrumentation (T/P/flow/conductivity/level), PLC/HMI/historian.

Back-of-the-envelope relations:

Industrial

Wastewater

/

ZLD

Pretreatment

Concentrate

high-salt

or

organics-laden

streams

to

lower

final

solids

burden.

Lithium

Brine

&

Chemicals

Tight

control

of

concentration

steps

with

seamless

handoff

to

crystallization.

Dairy

&

Food

Heat-sensitive

products

benefit

from

small

ΔT

and

controlled

residence

time.

Pharma

/

GMP

Hygienic

materials,

validated

cleaning,

and

complete

batch

records.

Representative industries served by MVR evaporation systems.

Provide upfront: feed rate, initial/target solids, BPE, viscosity-temperature curve, allowable ΔT, scaling factor, corrosives (Cl⁻/F⁻/H₂S), annual operating hours, and utility boundary conditions.

Common materials: SS316L, duplex 2205/2507, titanium & Ti‑Pd, Hastelloy (selected by corrosion chart vs. budget).

Compressor selection:

Automation: adaptive evaporation rate & concentration, vacuum/surge control, ΔT protection, sequenced CIP, energy KPI dashboards.

| Criterion | MVR Evaporator | Multi-Effect (MEE) | TVR |

|---|---|---|---|

| Fresh Steam Dependence | Very low (mostly electric) | Medium to high | Medium |

| Start/Stop & Load Following | Good | Fair | Fair |

| Maintenance Complexity | Medium (compressor-centric) | Medium | Low-Medium |

| High-BPE / High-Salt Suitability | Staged designs handle it well | Needs more effects | Limited |

| Typical Total Cost of Ownership | Medium-High (shorter payback) | Medium | Medium |

Feed: 50 m³/h at 8% TDS → Target: 35% (mother liquor to crystallizer)

Train: Two-stage MVR in series + preheater + online CIP

Takeaways: Dramatically reduced fresh steam and cooling water; continuous run ≥ 20 days then single CIP; tight quality variance.

Generic example only. Final design must be confirmed by lab data and heat/mass balance.

Why

is

an

MVR

evaporator

more

energy‑efficient?

By

compressing

secondary

vapor

and

reusing

its

latent

heat

for

boiling,

MVR

slashes

fresh

steam

demand.

Electricity

drives

the

compressor,

keeping

energy

levels

matched

to

the

duty.

Is

MVR

suitable

for

high-salinity

or

high‑BPE

feeds?

Yes.

With

staged

design,

extra

heat-transfer

area,

and

tuned

ΔT/velocity,

MVR

is

common

in

ZLD

pretreatment

and

salt

crystallization

front‑ends.

How

often

does

the

compressor

need

maintenance?

Intervals

vary

by

model

and

load.

Focus

areas

are

bearings,

seals,

and

surge

protection

control.

Good

setpoints

and

condition

monitoring

extend

service

windows.

Can

the

system

meet

GMP

or

food-grade

requirements?

Yes.

We

offer

hygienic

materials,

smooth

weld

finish,

drainability,

validated

CIP/SIP,

and

documentation

aligned

with

your

quality

system.

Can

MVR

integrate

with

crystallizers

or

membranes?

Absolutely.

Common

trains:

pre‑concentration

MVR

+

forced‑circulation

crystallizer,

or

MVR

paired

with

NF/RO

to

optimize

overall

energy

use.