Industrial

MVR

Evaporator

-

Zero

Liquid

Discharge

for

Sugar

&

Starch

Syrup

Engineer-to-order

Mechanical

Vapor

Recompression

(MVR)

evaporator

for

sugar

juice,

molasses,

and

starch

syrup

concentration

with

integrated

Zero

Liquid

Discharge

(ZLD)

options.

The

system

recycles

latent

heat

by

mechanically

recompressing

secondary

vapor,

delivering

low

OPEX,

stable

°Bx/DS

control,

and

minimal

effluent

for

sustainable

operation.

Key

Benefits

-

Energy

Efficiency:

Electric-duty

MVR

slashes

fresh

steam

use

after

start-up.

-

Product

Quality:

Vacuum/low

ΔT

evaporation

protects

color,

flavor,

and

DE;

tight

°Bx/solids

control.

-

ZLD

Readiness:

Condensate

polishing

for

reuse;

concentrate

routed

to

crystallizer/dryer

for

solids

discharge.

-

Hygienic

Design:

Food-contact

stainless

steels,

drainable

layouts,

optional

CIP/SIP.

-

High

Availability:

24/7

automatic

operation

with

redundancy

and

predictive

fouling

monitoring.

Process

&

Thermal

Economy

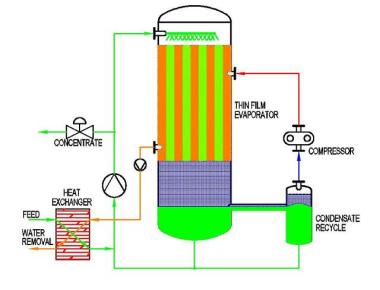

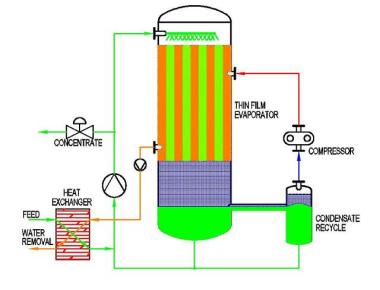

Secondary

vapor

is

mechanically

compressed

to

raise

saturation

temperature

and

reused

as

the

heating

medium.

Optimized

Δ

T/LMTD,

residence

time,

and

circulation

preserve

sucrose/invert

balance

and

DE,

while

enabling

deep

concentration

for

syrup

finishing

and

ZLD

schemes.

Materials

&

Hygiene

Wetted

parts

in

SS316L/duplex

(electropolish

on

request);

sanitary

connections,

food-grade

elastomers,

sloped/drainable

piping;

validated

CIP/SIP

supporting

HACCP/ISO

22000.

Process

Overview

--

Sugar

&

Starch

Syrup

ZLD

-

Feed

prep:

clarification/filtration,

pH

trim,

degassing

to

minimize

color

pickup

and

scaling.

-

MVR

evaporation

(vacuum):

falling

film/forced

circulation

with

tight

ΔT

for

gentle,

efficient

concentration.

-

Condensate

polishing:

filters/RO/AC

to

meet

reuse

(process/CIP)

or

discharge

limits.

-

Finishing/ZLD:

syrup

to

target

°Bx/DS;

mother

liquor

to

crystallizer/centrifuge/dryer

for

solids

discharge.

-

Automation:

PLC/HMI

recipes

for

crop/seasonal

variability,

alarm

interlocks,

historian,

remote

support.

Key

Components

-

MVR

evaporator

(falling

film

/

forced

circulation)

with

vapor-liquid

separator

-

Mechanical

vapor

compressor

(turbo/Roots)

with

VFD

-

Preheaters,

main

heater,

condensers,

vacuum/NCG

handling

-

PLC/HMI/SCADA;

instruments

(T/P/flow/cond/level/°Bx

or

DS)

-

CIP/SIP

skid;

condensate

polishing

filters/RO;

optional

aroma

capture

Performance

&

Sizing

|

Parameter

|

Typical

Range*

|

|

Operation

|

Continuous,

24/7

|

|

Electric

use

(MVR)

|

~15-40

kWh

per

ton

of

water

evaporated

(duty/CR

dependent)

|

|

Product

temperature

|

Low-temp

vacuum

duty

to

protect

color/DE

and

reduce

inversion

|

|

Sugar

syrup

(°Bx)

|

e.g.,

60-75

°Bx;

tighter

spec

via

inline

°Bx/viscosity

control

|

|

Starch

syrup

(DS/DE)

|

e.g.,

70-85%

DS;

DE

preserved

with

gentle

ΔT

and

residence

time

|

|

Condensate

quality

|

Polished

for

reuse

(process/CIP)

per

site

standards

|

|

Materials

|

SS316L/duplex;

Ti/Hastelloy

available

for

corrosives

|

*Performance

depends

on

feed

composition,

viscosity/fouling

tendency,

compression

ratio,

and

heat-exchanger

design.

FAQ

Can

one

line

handle

both

sugar

and

starch

syrup?

Yes--recipe-based

setpoints

(ΔT,

residence

time,

pressure)

and

sanitary

changeover

enable

multi-product

operation.

How

is

product

quality

protected?

Vacuum

boiling

lowers

temperature;

uniform

thin

film

and

tight

ΔT

minimize

color

formation

and

inversion/degradation.

How

does

ZLD

integrate?

Condensate

is

polished

for

reuse;

mother

liquor

proceeds

to

crystallization,

centrifugation,

and

drying

for

solid

discharge.

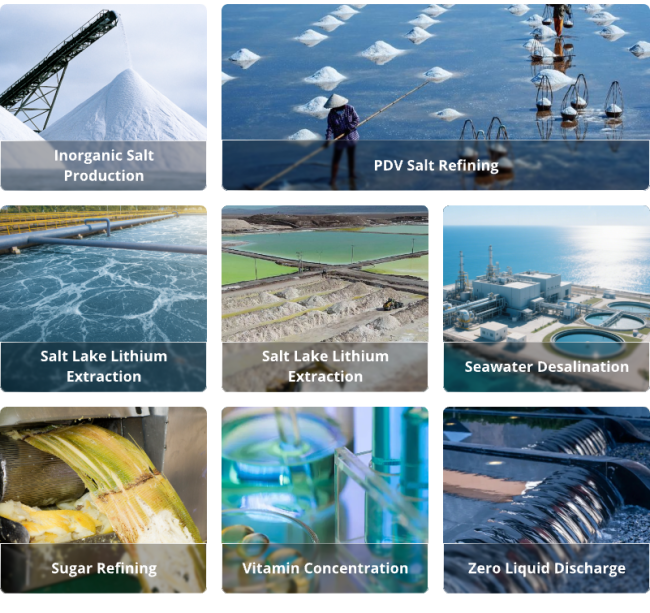

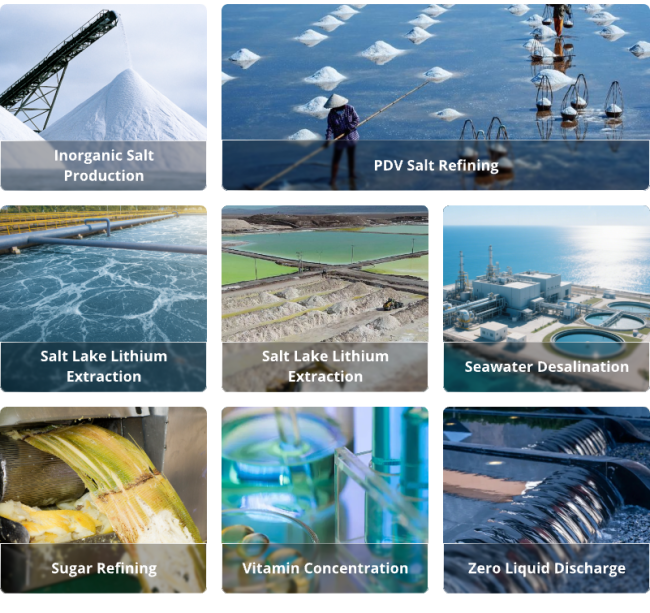

Application