| Price | Negotiation |

| MOQ | 1 set |

| Delivery Time | 15-90 Working Days |

| Brand | Jinwang |

| Place of Origin | Made in China |

| Certification | CE, ISO9001 |

| Model Number | LP-300H |

| Packaging Details | Wooden Case Packing |

| Payment Terms | L/C, T/T |

| Supply Ability | 1 set per month |

| Place of Origin | Made in China | Shape | High-speed rail |

| External Dimension | 3450×2245×2030mm(L×W×H) | Power Source | ~220V 50Hz/3KW |

| Packaging Details | Wooden Case Packing | Air Source | 0.5-0.7MPa |

| Material | SUS304 | Model Number | LP-300H |

| Scope of application | 50-1000ml | Supply Ability | 1 set per month |

| Certification | CE, ISO9001 | Weight | About 1000kg |

| Brand Name | Jinwang | Payment Terms | L/C, T/T |

| Price | Negotiation | Delivery Time | 15-90 Working Days |

| Capacity | 100ml:≥18000bottles per hour | Minimum Order Quantity | 1 set |

| Bottle Diameter | Round bottles:Φ40-95mm Bottle Height 80-240mm | Model | LP-300H |

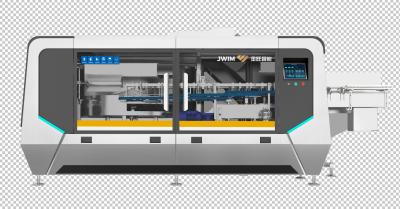

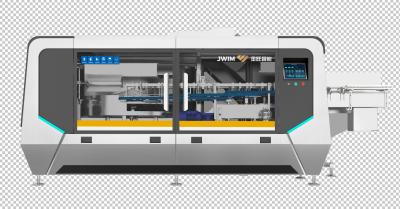

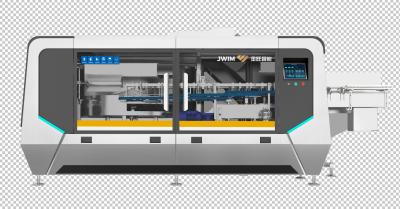

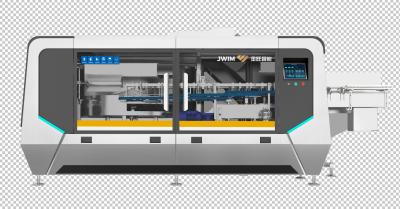

18000bph Automatic Bottle Unscrambler Machine 50-1000ml Round Bottle Compact Easy

1. Introduction of Automatic Bottle Unscrambler

The LP-300H automatic bottle unscrambler is suitable for any kind of round bottle with a speed of over 18000BPH.

Our bottle unscrambling machine consists of a bottle loading machine, a bottle unscrambler turntable, a bottle reject component, a bottle unscrambler component, an inverted bottle rejecting component, and an electrical box. A large number of disordered bottles are put into the bottle unscrambler turntable by the bottle loading machine and are transferred to the unscrambler part through the conveyor belt so that the bottles can be conveyed upright to the user's conveyor belt.

The machine is best suitable for bottle production lines, suited for production like Cosmetic, Agrochemical, Pesticide, beverage, dairy, household products, personal care, pharmaceutical, motor oil, Edible and Lube oil, pharmaceutical, Nutraceutical and vitamin industries.

2. Technical Parameters

| 1 | Unscrambling Speed |

100ml: ≥18000bottles per hour *speed will be affected by the bottle size, bottle material |

| 2 | Bottle Diameter | Round bottles:Φ40-95mm Bottle Height 80-240mm |

| 3 | Air Source | 0.5-0.7MPa |

| 4 | Power Source | ~220V 50Hz/3KW |

| 5 | External Dimension | 3450×2245×2030mm(L×W×H) |

| 6 | Weight | ~1000Kg |

3. Electric Allocations of 50-1000ml Bottle Unscrambler

| No. | Name | Brand |

| 1 | PLC | Schneider |

| 2 | Touch Screen | Schneider |

| 3 | Frequency converter | Schneider |

| 4 | Count Photoelectric | SICK |

| 5 | Switching power supply | Schneider |

| 6 | Solenoid Valve | FTEC |

| 7 | Circuit Breaker | Schneider |

| 8 | Intermediate relay | Schneider |

| 9 | Alarming Light | Schneider |

| 10 | Exhaust Fan | SUNON |

| 11 | Turbo Reducer | UCAN |

| 12 | Motor | UCAN |

4. Features of Bottle Unscrambler Machine

a. High Speed: over 18000 bottles/h.

b. The whole machine adopts a high-speed rail appearance with a strong sense of technology, beautiful and high-grade.

Operating Status

Standby Mode

Shutdown Alarm Status

c. Compact structure, simple operation, good universality for 50-1000ml bottles.

d. Do not need to change the mold when changing different size of bottles.

e. The bottle loading machine adopts a new mechanism, and the bottle opening is wide enough to ensure the efficiency of bottle loading.

f. Equipped with coordination sensor, inverted bottle removal function, and automatic bottle elevating function, efficient and accurate.