| Price | negotiation |

| MOQ | 1 set |

| Delivery Time | 15-90 work days |

| Brand | JWIM |

| Place of Origin | China |

| Certification | CE,ISO,GMP |

| Model Number | CCG5000-12TS |

| Packaging Details | wooden cases |

| Payment Terms | L/C, T/T |

| Supply Ability | 1 set per month |

| Air supply | Clean dry compressed air supply | Place of Origin | China |

| Air pressure | 0.6-0.8 Mpa | Packaging Details | wooden cases |

| Power supply | 380V 50Hz | Model Number | CCG5000-12TS |

| Supply Ability | 1 set per month | Certification | CE,ISO,GMP |

| Name | 1-5L Liquid Detergent Filling Machine | Brand Name | JWIM |

| Payment Terms | L/C, T/T | Accuracy | ±5g(1000mL) ±10g(5000mL) |

| Price | negotiation | Delivery Time | 15-90 work days |

| Capacity | 1800 BPH | Minimum Order Quantity | 1 set |

| Filling range | 1L-5L | Machine weight | 1850 kg |

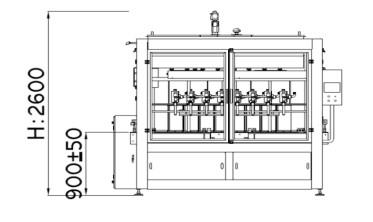

| Power | 2.2KW | Machine size | 3000×1210×2600mm |

1800 Bottles Per Hour 1-5L Liquid Detergent Filling Machine with 12 Filling Nozzles

Introduction of 1-5L liquid detergent filling machine:

CCG5000-12D Intelligent High Viscosity Filling Machine is suitable for packing various kinds of high viscosity material. The whole machine is in-line structure, using servo motor drive and volume metering filling principle to achieve high accuracy of filling dose. With PLC control and touch human-machine interface, the whole machine is easy to operate and intuitive.

Parameters of 1-5L liquid detergent filling machine:

| 1 | Capacity |

3000ml≈1800

bottles/hour |

| 2 | Suitable size |

Round

bottle:Φ80-140mm

Height140-340mm |

| 3 | Volume | 1000-5000mL |

| 4 | Accuracy | ±5g(1000mL) ±10g(5000mL) |

| 5 | Feeding port height | 2400mm |

| 6 | Feeding port diameter | Dn40 |

| 7 | Nozzle diameter | Φ26mm |

| 8 | Minimum bottle opening size | ≥Φ30mm |

| 9 | Air pressure | 0.6-0.8MPa |

| 10 | Power | ~380V 50Hz/2.2KW |

| 11 | Machine dimension |

3000×1210×2600mm(L×W×H) |

| 12 | Weight | About 1850Kg |

| 13 | Weighing feedback, the maximum range is 6Kg, if the material proportion is more than 1.2, it should be customized according to the actual situation. (Optional) | |

| S/N | Name | Brand | Remarks |

| 1 | Servo system | Schneider |

|

| 2 | PLC | Schneider | |

| 3 | Counting sensor | Sick | |

| 4 | Touch screen | Schneider |

|

| 5 | Solenoid valve | SMC |

|

| 6 | Circuit breaker | Schneider | |

| 7 | Converter | Schneider | |

| 8 | Alarm light | Schneider | |

| 9 | Buttons | Schneider |

|

| 10 | Proximity switch | LEUZE |

|

| 11 | Pressure switch | SMC |

|

| 12 | Switch power supply | Schneider |

|

| 13 | Cylinder | SMC |

|